Automotive Manufacturing Process

Automobile manufacturing is a time consuming process and requires a variety of units and technicians to work in cohesion. Ideas for new car models are dependant on the unmet motoring needs of the people. However, the job of visualising an automotive model which will be popular among a generation five years in the future is no easy task. The designers initially start brainstorming on a concept car which would be functional and have some fresh element in it as well.

The designing stage involves the designers to use computer simulations and sketches for getting that design and ergonomics which would finally be realized in the form of the final model. The sketches and computer aided designs assist the designers in chiselling out a clay model, which would subsequently put under the microscope for further corrections. The styling experts are then summoned for modifying the clay model further. The ergonomics and streamlining work is left to the aerodynamic engineers who test the model on various parameters such as studying air-flow and feasibility studies on crash tests. Only when all the specialists unanimously accept the design, it’s passed on to the next stage of automotive production.

The tool designers are the technicians who are put into play next. Cutting edge tools are ether assembled or manufactured for shaping the car in the assembly plant. Most often virgin steel is the preferred material for making automobiles, however petroleum based products such plastics and vinyl are used in conjunction with steel too. As such, components made from petroleum based products have an advantage-they’re comparatively light. As a result, in the last few years we’ve seen automobiles which are more fuel efficient owing to their lighter weight.

The automotive assembly plant is the place where the car is finally created. However, the components of the car are most often supplied from various corners. There can be about five thousand individual suppliers who are assigned the job of supplying specific parts of the automobile. The suppliers are a combination of outside suppliers and company owned parts suppliers. The components are transported to the plant through railroad or trucks. Generally, the components pertaining to the chassis and the ones for the automobile body are unloaded in two different areas.

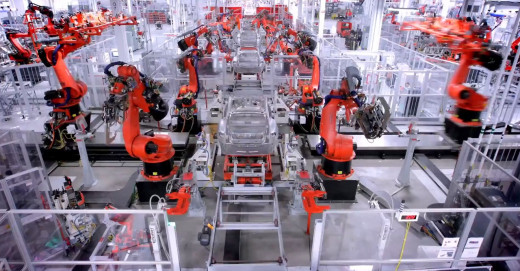

The chassis is constructed from the ground up. The frame comes first, which is tightly attached to the conveyor and then it starts moving down the line. Initially, the front and rear suspensions are clamped onto the frame, followed by gas tanks, rear axles and drive shafts, gear boxes, steering box components, wheel drums, and braking systems which are installed sequentially. During this stage, an off-line operation mates the automobile’s engine with its transmission. The technicians use robotic arms for installing the heavier components inside the frame’s engine compartment.

After this primary stage of production completes, workers manually install the radiators. Presently, the top of the line automotive assembly lines deploy robots for wrenching bolts or lifting the heavy components.

After that, the components of the car body which have been shipped are removed from pre-staged shipping containers and placed on the floor. The largest of the components is the floor pan on which various other small components are welded. Other components include the quarter panels, the front and rear door pillars, roof and side panels which are either welded or clamped to the frame. This job is usually rendered by robots, since it requires a degree of accuracy and tolerance to harsh environments like smoke, gases and weld flashes which is impossible for human workers to handle. Finally, the work on the automotive body is complete as the fully assembled doors, deck lids, hood panel, fenders, trunk lid, and bumper reinforcements are installed one by one. The robots are complemented by workers with pneumatically assisted tools during the body making process.

2013 Mercedes C Class Production Process

If given an offer, which auto manufacturing plant would you visit?

Thereafter it is time for the paint job. Prior to the spray painting, the vehicle goes through yet another inspection stage wherein all traces of scratches and dents are removed in a brightly lit room. This stage is named the Body in White operation. After repairs, the automobile shell is put through an undercoat dip (E-coat) where the primer is applied. The shell’s then dried and spray-painted by robots (Although some manufacturing plants still use workers for painting with a brush). The painting stage comes to a close when the body is passed through a baking oven (It’s temperature reaching 135 degrees Celsius) which cures the paint and the automobile is all set for the interior assembly.

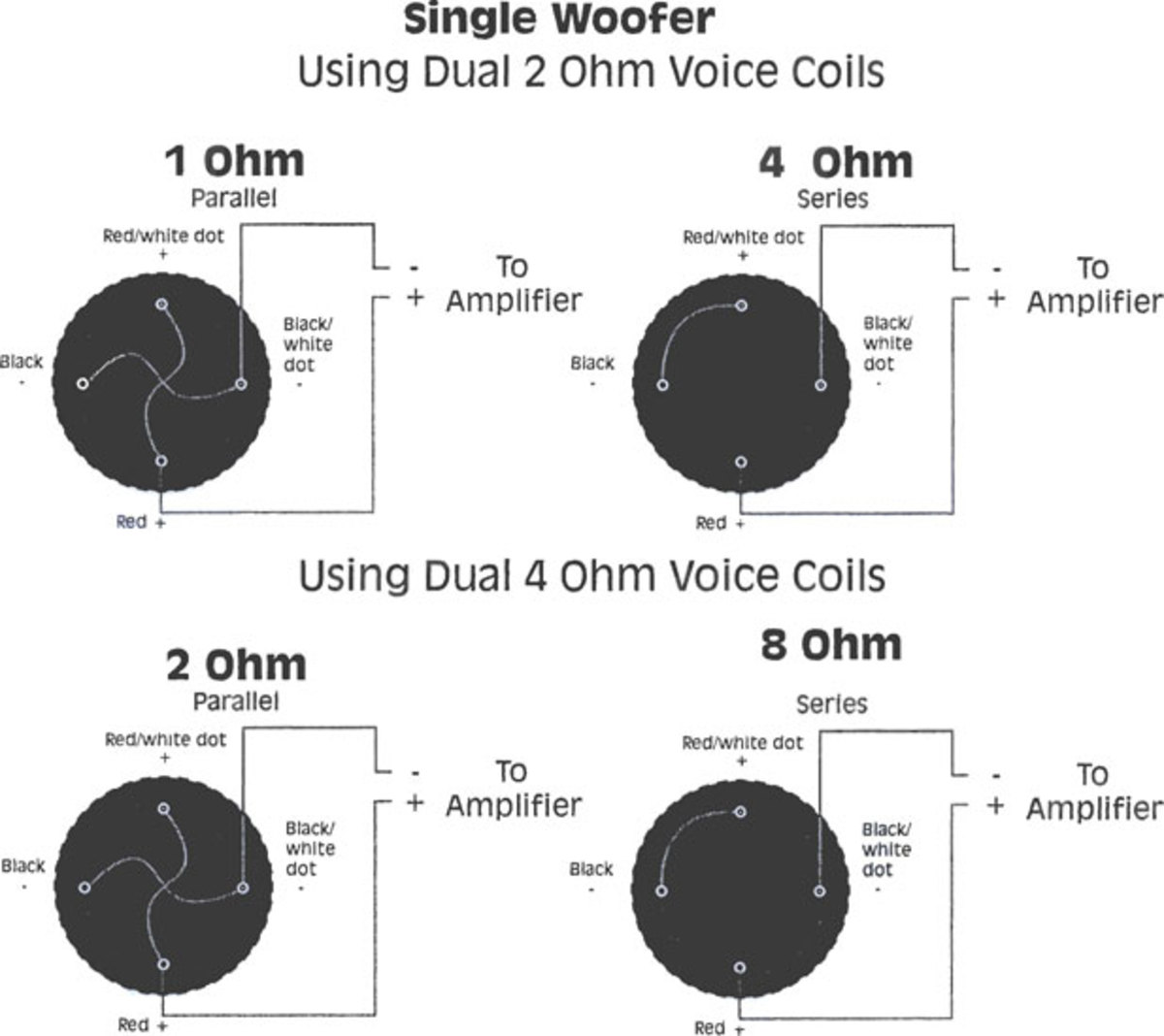

In the interior assembly, workers assemble the interiors such as the instrumentation and wiring systems, dash panels, interior lights, seats, door and trim panels, headliners, radios, speakers, all glass(Other than the automobile windshield), steering column, wheel, body weather-strips, front and rear bumper fascias ,vinyl tops, brake, gas pedals and carpeting. The windshield is generally installed by the robots using suction cups for lifting and placing them accurately. After a Water Test, the body gets set to mate with the chassis.

The next phase of production witnesses the stage where the chassis assembly conveyor and the body shell conveyor meet. The robots and workers work in unison to bolt the body on to the frame, so as to integrate them seamlessly. The automobile is still unfinished and continues down the line where final trim components, battery, tires, anti-freeze, and gasoline are added. The vehicle is now capable of being started and is driven to a checkpoint where each of it’s components such as headlights, horns and tires are double checked for safety and performance.

Each and every stage of automotive manufacturing has to go through rigorous quality control procedures. From the outside parts vendors whose component parts require to be Statistical Process Control (SPC) approved, to each individual automobile in the assembly plant getting tagged by a Vehicle Identification Number (VIN), the stringent measures ensure that the final product offers the highest safety standards and gives a zooming performance as well. The automobile is now complete, given a price label and shipped to it’s destination. Soon, the automobile will hit the road.