Motorcycle Brake Rotors

Motorcycle Brake Rotor

The Purpose of Brake Rotors

Motorcycle brake rotors serve two purposes in the braking system. First, brake rotors provide a flat surface for the brake pads to create the necessary friction for stopping. The second, and just as important, is the dissipation of heat. Anytime friction is present, heat is developed. Brake fade is typically caused by heat, and can significantly reduce the effectiveness of the brakes. In addition, motorcycle brake rotors that do not dissipate heat well will warp and breakdown prematurely. When rotors warp, brake pads will skip on the surface and cause dangerous vibration, along with decreased braking power.

Morcycle Brake Rotor Basics

Brake rotors are typically manufactured from iron or stainless steel. Both provide good braking surfaces, but stainless steel rotors come with some significant benefits. Stainless steel rotors offer greater durability than iron. Being resistant to rust helps lengthen the motorcycle rotor’s life and helps keep the aesthetic value. Brake rotors can be polished or chromed, but remember that polishing the surface may actually reduce the ability to create friction.

One Piece and Floating Rotors

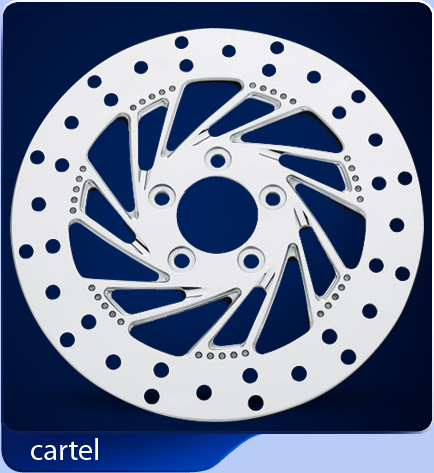

Motorcycle brake rotors are vented to help dissipate heat. Venting refers to the holes or slots machined into the contact surface. These vents allow provide more surface area for cooling and actually vent gases produced by the heat. A new type of brake rotor is becoming popular for performance motorcycle applications. Floating rotors use a two piece design. This two piece design incorporates a hub (interior ring) fastened to a friction plate (exterior ring). By fastening the hub via slotted holes, the friction plate is allowed to expand and contract independently of the hub, reducing warping under intense heat.

Matching Wheel and Rotor

Choosing Brake Rotors

Brake rotors come in a variety of choices for customizing your motorcycle or chopper. Rotors are available for both right-hand and left-hand applications, and some wheel manufacturers actually make rotors that match their wheel choices. This is a simple way to add considerable style to your custom chopper or motorcycle. Brake rotors are also offered in different diameters. Larger diameter rotors will dissipate heat better because of the increased surface area.

Brake Rotor Maintenance

Brake rotors should be inspected periodically because they will eventually deteriorate. Check for uneven wear, warping and fractures. Uneven wear can be caused by worn pads or malfunctioning calipers. Warping and fracturing are caused by the extremes of heating (expansion) and cooling (contraction). Maintaining a smooth, flat surface, will extend the life of the brake pads and help insure good stopping power.

Reference: Chopper Fundamentals 101 © 2007