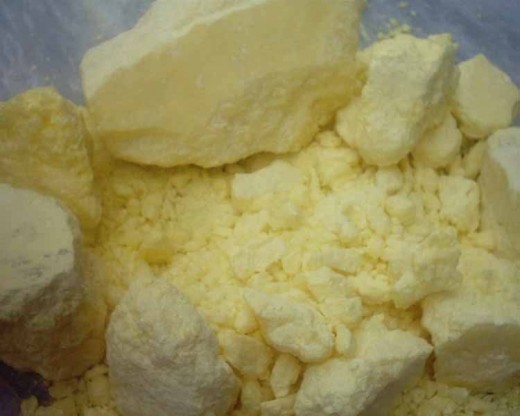

SULFUR CARGO

Sulfur is naturally found as mineral, mainly on volcanic regions. It is also a byproduct in petroleum industry. Sulfur is amber yellow in color. It is used for many purposes. The most important use of sulfur is in the manufacture of sulfur compounds such as sulfuric acid, sulfites, sulfates, and sulfur dioxide. Sulfuric acid is one of the most important industrial chemical. It is not only used in the manufacture of sulfur-containing molecules but also in the manufacture of numerous other materials that do not contain sulfur, such as phosphoric acid. Sulfur is also used in manufacture of fertilizers. Sulfur is also employed in the production of matches, vulcanized rubber, dyes, and gun powder. In a finely divided state and frequently mixed with lime, sulfur is used as a fungicide on plants. The salt Na2S2O3·5H2O commonly called hypo, is used in photography for fixing negatives and prints. When combined with various inert minerals, sulfur forms special cement used to anchor metal objects, such as railings and chains in stone.

Generally Sulfur is carried as bulk in bulk carrier vessels. Molten sulfur is transported in specially designed tankers equipped with heating coils in the tanks. Normally these tankers are type III chemical tanker vessels.

Dry sulfur does not react with steel, but because of the dust, Sulfur is loaded as wet Sulfur which is highly corrosive. Though the bilges are pumped out regularly, sulfurous mud remains in cargo holds. The corrosion can be divided into two types. They are acidic corrosion & electrochemical corrosion.

The acidic involves sulfuric acid, but corrosion is significant only after when pH reaches the value of two & less. Electrochemical corrosion is directly between the iron & sulfur, forming Ferrous sulfide, otherwise known as Makinawite. This is the main reason for corrosion while carrying Sulfur as cargo.

The other risk factors involved with Sulfur is, that it can emit Sulfur dioxide gas when heated. It can also emit Hydrogen sulfide. Good ventilation is important while carrying sulfur in cargo holds. Sulfur is flammable so precautions should be taken.

The measures to minimize the corrosion by Sulfur as follows. Good paint coating can remove the contact between iron & Sulfur. Lime washing should be carried out specially in cargo holds & inside bilges. Lime wash prevents corrosion by two methods. First it acts as physical barrier & secondly as an alkaline neutralizing barrier. Upon discharge of Sulfur cargo holds should be thoroughly washed, bilges to be pumped out several times. The rusted places should be chipped as soon as possible & painted.