Parmigiano-Reggiano: the real Parmesan

Lauded as the crème de la crème of cheeses for centuries, Parmigiano-Reggiano has been more widely imitated than any other cheese. Yet none have managed to even come close to the original; not even those made just outside its traditional zone of production. It has been acknowledged as one of the great cheeses of the world with production remaining fundamentally unchanged for the last eight centuries.

This best known of grana cheese is believed to have been born in what is today the Reggio nell'Emilia, rather than the Parma, side of the Enza River. However, boundaries in Italian history changed as frequently as underwear and in those early days Reggio nell'Emilia fell within the Duchy of Parma. Thereafter the cheese was referred to as Parmigiano and it was only in 1934 that Reggiano was added to recognise the equal importance of the province of Reggio nell'Emilia when the Consorzio di Tutela (the Consortium for the Protection of Parmigiano-Reggiano) was founded. It is claimed to that the best Parmigiano-Reggiano comes from the Reggio side of the river.

The term grana (literally, 'grain') refers to a category of hard aged cheeses, made from partially skimmed cows' milk and matured for 12 to 24 months. As the name indicates, these cheeses have an internal granular structure. In Italian slang, the word 'grana' also means 'money' or 'trouble'. Rather appropriate, when you think about the cost of Parmigiano-Reggiano and the intense rivalry between it and its arch rival Grana Padano which is produced in 27 provinces of Pianura Padana which fringe the Parmigiano-Reggiano area. Other grana cheeses include Grana Lodigiano from the province of Lodi and which Alexandre Dumas incorrectly identified as Parmesan (the French word for Parmigiano) in his Grand Dictionnaire de Cuisine, and Grana Bagosso from the Bagolino zone.

So, what makes Parmigiano-Reggiano so inimitably special? This is essentially a raw milk cheese which is cooked, and its success is a complex combination of terroir and productions methods, all strictly policed by the Consorzio since its formation and, since the 1950s, regulated by legislation. Further, regardless of adherence to these requirements, the final product must meet exacting standards before it can be classified as Parmigiano-Reggiano.

The zona tipica (defined area of production) for Parmigiano-Reggiano comprises the provinces of Parma, Reggio nell'Emilia, Modena, Mantova on the right bank of the Po river and Bologna on the left bank of the Reno river. Once swampland, this became a rich agricultural region in the thirteenth and fourteenth centuries when it was drained and irrigated. Cows of this region are renowned for producing the richest milk in Italy thanks to the highly nutritious fodder available. However, today there are no cows wandering the pastures; rather they are kept in stalls where they enjoy a sort of bovine room service with the farmer bringing the food to them. No chemicals or additives are permitted in the production of Parmigiano-Reggiano which is proudly proclaimed as the result of nothing more than 'milk, rennet and fire' (and some salt). This strict rule also extends to the feed which must be free of sprays; the feed mix is regulated and checked regularly by Consorzio inspectors.

Collectively Parmigiano-Reggiano is big business (some 2.9 million wheels were produced in 2009), but production remains highly fragmented. There are only some 650 small dairies (caselli), each producing anywhere between 4 to a maximum of 10 wheels a day. Science and technological advances have changed certain aspects of production: until 1984, production was only permitted between 1 April and 11 November, in line with the natural lactation period of the cow. Cheeses made outside this period are termed vernengo, not Parmigiano-Reggiano. Year round milking became possible as a result of artificial insemination. However, the cheese remains stubbornly resistant to mass production; refusing to harden or mature under such conditions, and even worse, developing swelling (an indication of bacterial rot). One possible explanation of this recalcitrant behaviour is that each dairy sits within a micro-ecosystem which is optimal for the milk in that small area with its own distinctive and homogenous bacterial flora that suffers if mixed with those of other areas.

The Art of Parmigiano-Reggiano

Like many artisanal cheeses, Parmigiano-Reggiano production is more art than science. As scientist Dr Leo Bertozzi states: "in my opinion, fine cheese is 30% the milk and 70% the skill of the cheesemaker." A Parmigiano-Reggiano cheesemaker (casaro) serves a 10 to 14 year apprenticeship after which he embarks on a lifetime's work without any holidays until retirement. The casaro's skilled judgement is called upon through every stage of the production.

The cheese is made from the milk of two successive milkings. The evening milk stands in stainless steel trays for at least 12 hours during which time cream comes to the surface and fermentation begins. The next day part of the cream is skimmed off and used to make butter. (The resultant butter is said to be more aromatic and flavoursome than that obtained by normal centrifugation.) Determining the amount of milk to be skimmed off is part of the casaro's skill. The aim is to leave as much fat in the milk as its protein content can support because the higher the fat content, the greater the cheese's aging capacity. (Protein levels vary with seasons.)

This partially skimmed milk is then blended with fresh milk from the morning's milk and poured into huge, bell-shaped copper-lined vats. (Whilst these vats were once solid copper, today they are usually made of cast iron with a copper lining.) Copper is important because it not only acts as a very efficient heat conductor but it also causes an acidic reaction with the milk. It takes about 500 litres of milk, which equates to the daily yield of about 40 cows, to make a single wheel of Parmigiano-Reggiano.

The blended milk is then slowly heated. Whilst it is heating, the siero innesto or starter whey is added. This is the whey from the previous day's cheesemaking which has been left to ferment overnight to develop lactic acid. (The amount to be added depends on the acidity of both the whey and the milk and perfect balance is crucial.)

The milk is continuously stirred with a paddle, nowadays electrically powered where it was once done by hand. Once the milk reaches 33ºC the heat is turned off but the liquid continues to swirl around the vat. Rennet is added for coagulation to occur within 12 to 15 minutes: the amount depends on the level of protein and the pH of the milk to occur. The casaro watches over the coagulation process like a hawk, constantly testing the curds to see if they have reached the critical point to be broken up.

As soon as the curd is deemed to have reached the requisite point of coagulation, it is then manually broken up into tiny cubes with an instrument called spino. Modernisation has replaced this original thorn brush (from which this instrument gets its name) with a steel contraption that resembles a giant egg whisk, but this curd-breaking process 'rottura della cagliata' has yet to be mechanised. The casaro labouriously works the spino every which way to achieve the requisite tiny grains for a compact cheese.

During the breaking up process, the mixture is slowly reheated to around 45ºC to firm up the curds and facilitate the separation of whey. Again this process is closely monitored by the casaro as the behaviour of the milk will change from one day to the next. When the temperature reaches 45ºC, the heat is then increased to quickly take the milk to precisely 55ºC and the curds are allowed to cook very briefly. At 55ºC the temperature is high enough to kill off any potentially harmful bacteria without destroying the beneficial organisms that are responsible for flavour development.

After the heat is turned off, the curds form a mass at the bottom of the vat. Different cheese makers allow this mass to rest for different lengths of time. Most rest it for 20 to 30 minutes, some leave it longer in the belief that the longer resting time makes for a more compact cheese. At the end of the resting time, the massive curd ball is lifted out of the vat and slipped into a 'hammock' of cheesecloth to drain off the whey. A portion of the whey is kept and fermented to be used as a starter the following day. The rest of the whey is used to clean out the vats or is fed to pigs for the production of the renowned prosciutto di Parma.

The drained mass is either cut in half or left whole (two is the maximum number per vat), each wrapped in cheesecloth and gently kneaded. Each curd mass is then set in a large cylindrical wooden mould (fascera) on large draining tables, the casaro gently pressing it to expel any remaining whey. It is weighted down with a heavy wooden slab that forces out more whey as well as slowing down the cooling process. Each hour, the curd mass is turned and every second hour, the cloth changed.

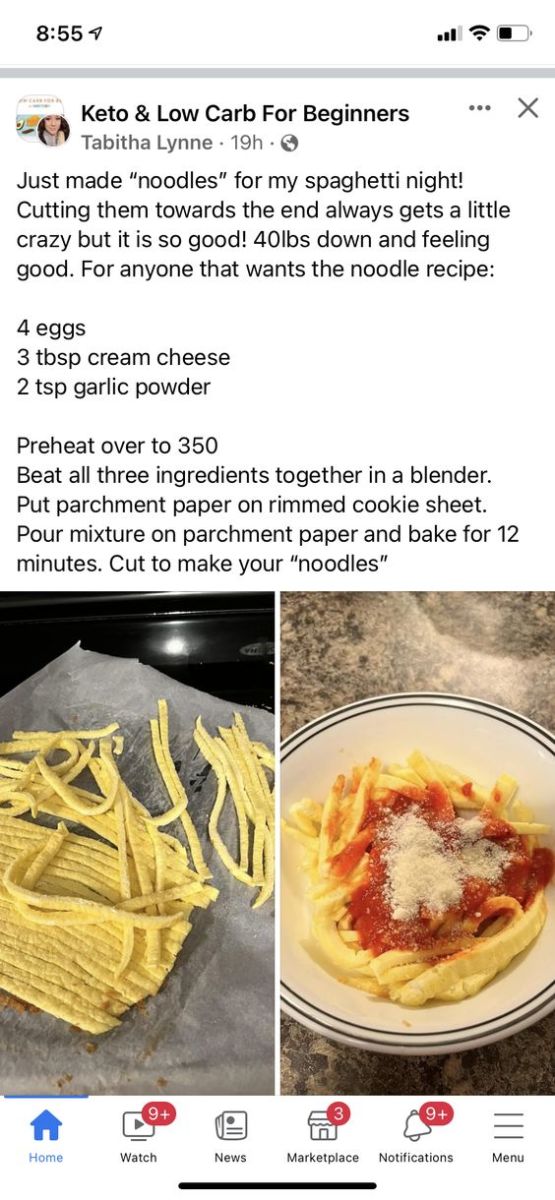

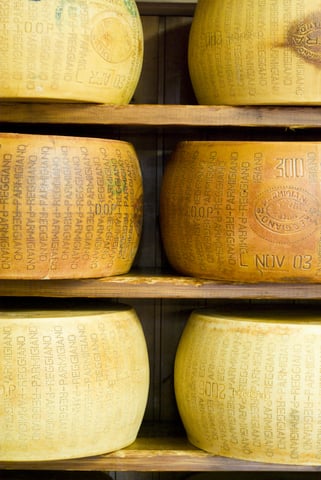

After several more hours, the curd mass will be quite firm and it is then taken out of the fascera. The cloth is removed and the mass is fitted with a stainless steel matrix band which indents the word Parmigiano-Reggiano in tiny pin-pricks on the exterior. Also indented are the cassello's code number and the year and month of production. The bands that give each potential wheel of Parmigiano-Reggiano its 'birthmark' are closely monitored by the Consorzio to preclude counterfeiting. Such markings, together with detailed records kept by the casaro, ensure than any problems can be traced back to each individual producer. The newly formed cheese is left to drain for several days, periodically turned ruing that time after which it will have firmed up sufficiently to hold its characteristic barrel shape on its own without distortion. The restricting corsets are removed and the cheese spend the next 20 to 25 days immersed in a salt bath during which it is turned every day to ensure an even penetration of salt.

Once out of its brine bath, the cheese is left in a warm (about 20ºC) place to drain and 'sweat' out further liquids before it starts its long residence in the cascina - a storehouse with large wooden shelves, also known as a cheese bank. Given the value of their contents, cheese banks are kept under tight security. Robberies of such banks have been known to occur although one would have thought that disposal of the spoils would be difficult, if not impossible, as these cheeses are akin to clearly identifiable marked bank notes.

During the aging process, the cheese continues to be lovingly tended - inspected, turned, brushed and rubbed down regularly. The Consorzio inspectors also start making their checks. The slightest flaw such as a dent in the crust will result in a cheese being rejected. The worst ailment is bacterial rot as indicated by swelling of the cheese. The inspectors tap the cheese with a small hammer called a martello, and based on the sound, are able to determine whether there are any holes in the cheese. A needle-like instrument called ago is inserted to check the fragrance of each cheese. The degree of resistance encountered when inserting the ago into the cheese also provides an indication of its internal structure.

Any cheese found to fall short of the requisite standards is marked with Xs to obscure the words Parmigiano-Regginao. Termed 'scarto' or 'grana da pasto', these rejected wheels are sold for a fraction of the price of Parmigiano-Reggiano in the domestic market. (They are never allowed to be exported.) The rejects don't go to waste though. As the late Elizabeth David noted in her Italian Food: "Special dishes have been devised to make use of the new cheeses which, delicious as they are, are considered not good enough to justify the long maturation periods. One of these dishes, fonduta alla Parmigiana, is made with alternate layers of sliced Parmesan, white truffles, and grated Parmesan, melted in a small pan in the oven."

Those that pass inspection are fire-branded with the Consorzio's seal but only after 12 months have elapsed from the time of making. There is also an additional export quality mark ("Parmigiano-Reggiano EXPORT") which is affixed to cheeses with a minimum of 18 months aging.

Gradings for Parmigiano-Reggiano

There is only one Parmigiano-Reggiano but there are literally hundreds of Parmesans. Unfortunately when the international agreement to formalise the definition and qualifications took place in 1951, limitations were only placed on the use of the word 'Parmigiano-Reggiano' but not 'Parmesan'. Hence, the multitude of imitations, often sawdust-like, being sold as Parmesan.

True Parmesan - Parmigiano-Reggiano - is pale straw in colour with clean crystalline flakes of amino acids that gives the sensation of angels dancing on your tongue. Not all Parmigiano-Reggianos are equal either. There are in fact four grades: the highest is Reggiano Extra or Testa.. This is followed by Scelto, then Sotto Scelto Bello and last of all Sotto Scelto.

Parmigiano-Reggiano is also categorised by age: vecchio (2 years old), stravecchio (3 years) and stravecchione (4 years). In the past, a cheese could be aged up to 20 years or more, improving with each year. However, the milk from which the cheeses are made today is not considered to have the protein and fat content necessary to sustain such lengthy aging. A change in the type of cows, from the traditional 'red cows' (Vacche Rosse or Razza Reggiana) to the northern European breed Frisona since World War 2, underlies the decline in aging potential of this cheese. Whilst the Frisona yield more milk (their local nickname is 'milk machines') than the Vacche Rosse, the protein content of the milk of the Frisona is much lower and thus cannot sustain as much fat in the cheese making process. The lower the fat content, the lower the potential for ageing. There are a few producers however, who continue to make their cheese from Vacche Rosse milk and their product, which obviously is more expensive, carries a special mark of two cows drawing a cart in recognition of the superior qualities of the product.

Care & Handling of Parmigiano-Reggiano

A wheel of Parmigiano-Reggiano is never cut. Instead, the cheese is 'broken' using two special almond shaped knives. Cutting it destroys the delicate crystalline structure of the cheese that is so unique and important for enjoyment of its texture. Individual wedges should be 'cut' so that they retain enough rind to afford some protection of the cheese as well as provide evidence that it is indeed the genuine article.

Once broken and exposed to air, Parmigiano-Reggiano, like any other cheese, will gradually lose flavour and moisture. A solid wedge from a freshly broken wheel, wrapped in cheese paper or better still, in a hemp cheese bag (available from fine cheese retailers) and stored in the butter compartment or lowest rung in the refrigerator, should remain in excellent condition for up to three months. Never buy pre-grated cheese (the damaging exposure to air is accentuated) unless is it grated before your eyes and you intend to consume it in the next day or so. Also, ensure that you buy from a supplier with a high turnover to ensure that your wedge comes off a freshly broken wheel.

Enjoying Parmigiano-Reggiano

Parmigiano-Reggiano, like all grana cheeses, has wide cooking applications although it is best known as a grating cheese. Even the rind can - and should - be used as a flavour enhancer when making soups and stews. Freshly grated Parmigiano-Reggiano is the backbone of the classic pesto sauce. In Italy it is termed formaggio di rifinitura, which literally translates as 'cheese of a finishing touch', reflecting its use as the final touch in soups, pastas and risotto, salads and other first and main courses. However, its role is to enhance rather than fight with or drown out other flavours. Indiscriminate heavy-handed use over pasta dishes is a common sin, the worst being its use in seafood pastas. Parmigiano-Reggiano generally does not sit well with seafood although oily fish such as sardines and anchovies are exceptions to the rule. It is also tricky to match with wild mushrooms.

Beyond being a grating cheese, it is an excellent table cheese. Indeed, Parmigiano-Reggiano, preferably served as a chunk to be broken at the table with its own appropriate knife, is ideal not only as a cleansing finish to a meal but also as an elegant started with a dry, sparkling wine.

A wise man once said that "life is too short to drink bad wine" and a wiser woman added "and eat bad cheese." Why settle for wannabe parmesans? Get your Parmigiano-Reggiano from a good retailer who will ensure that you have a properly cared for hunk of this wonderful cheese - and have those angels dancing on your tongue!