- HubPages»

- Games, Toys, and Hobbies»

- Toys for Kids»

- Building & Construction Toys

Lego Technics Gear Machines

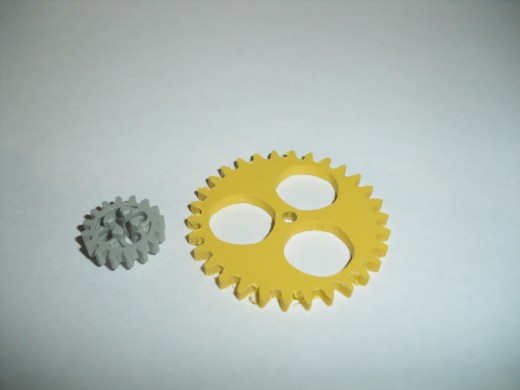

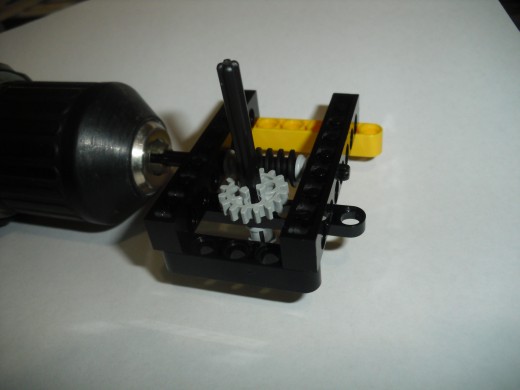

The gear on the left is a Lego Technics component, made of acrylonitrile butadiene styrene (ABS), while the gear on the right, the yellow one, is a custom made, built at home gear, milled from polyvinyl chloride (PVC). The homemade gear interfaces with the Lego brand gear, allowing a more direct pathway to certain gear ratios, which would otherwise have been very difficult to implement.

This is my first attempt at making a machine with Lego Technics. With no particular idea in mind, I decided to build a worm gear to spur gear mechanism to convert a high speed motor (a DeWalt drill) to a low speed high torque output. It works great, I wish I had more of these toys, but can't find where to buy them locally.

It is apparent that with a great many Lego Technic parts, universality can be achieved, meaning anything can be built. And if for some reason a machine cannot be built, such as a gasoline powered internal combustion engine, simply for the reason that ABS plastic cannot withstand the heat, the machine may be simulated by a Lego Technic based computer employing pneumatic valves for logic gates. In otherwords, if not physically possible, it is still always virtually possible.

In some situations, like building a wind up clock, or a differentially analog computer, custom made components that supplement the natural abilities of Legos would great help reduce part counts.

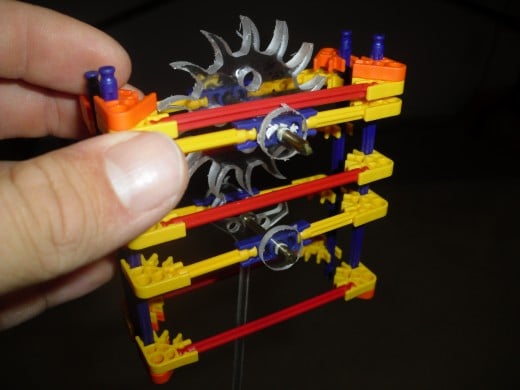

This machine, pictured above, uses a custom made pair of clock parts called an escapement wheel and the pendulum (with anchor attached). When driven by a power source, such as a wind up spring, an electric motor, or a wound up weight, the escapement wheel transfers power to the pendulum, which incidentally causes intermediate motion of the escapement wheel. This phenomenon, known as the process of escapement, causes the unwinding of the clock to occur at a predictable rate, meaning the clock keeps time, while simultaneously mechanically driving the gear train to display hours and minutes.

Specialized machines like these can in fact be built from Legos alone, or K'Nex, but doing so requires extra parts, and possible imperfection due to limited degree of precision which can possible be obtained. The escapement wheel's teeth have a very specifically calculated angle which helps maximize power efficiency (how long the clock can tick from a given spring) and how accurately it will keep time. Poorly cut teeth will lead to poorly tracked time. For this reason, these parts should be custom made, but this may be illegal in certain Lego contests or simply cause distress in the Lego purist. Regardless of opinion over the matter, the science of the matter dictates, custom parts allow for advanced mechanisms. The Legos (or K'Nex) provide an efficient platform for quickly prototyping design ideas and can be useful in the professional workplace.