How to Gain Service Access to Whirlpool Kenmore Kirkland Washers

Instructions for Disassembly

These instructions pertain to the various direct drive machines marketed under various brand names.

Specific instructions detailing the repair and or replacement parts will be detailed in additional articles regarding the replacement of lid switches, pumps, motor, coupler, timer and water valve. These are all do-it-yourself repair jobs and can be done by the home handyman. The instructions are specific and you will be able to have a high degree of success.

These instructions can be followed by anyone who wants to do their own repairs:

- Safety First - remember to follow all safety precautions.

- Follow the instructions and study the photos.

- Where ever I say be cautious, follow my advice, I don't want you to hurt yourself.

- Good luck and don't feel afraid to ask questions, I will respond as soon as I can.

Whirlpool, Kenmore, etc.

Whirlpool, Roper, Estate, Kitchen Aid, Kirkland

These are the Whirlpool or made by Whirlpool machines that have a direct drive system and these directions are specific to them:

Whirlpool makes many other brands: Kenmore, Roper, Estate, Kitchen Aid, Kirkland, and others. This comprises about 30% of the market, followed by GE with about 25%. An additional 20% is made under the Kenmore Sears brand name, but is manufactured by the major makers.

Whirlpool has also taken over various other brands : Admiral, Amana, Jenn-Air, Magic Chef, and Maytag. These are not direct drive machines.

All top loading machines that have a direct drive system are similar for repair procedures. If your washing machine does not have a belt, then it is a direct drive machine. Belt driven machines are completely different and have other solutions.

Don't Make these Mistakes

Common mistakes made by do it

yourselfers: (Safety Procedures)

Machine cannot be accessed from the back or bottom. Access in this manner will take way more time, defeats the design for service, and most probably will damage your machine.

Machine needs to be serviced in a minimum of space.

Reassembly requires that the case be locked in, this is critical to proper operation.

Hold down clamps are re-installed up side down.

Damage is done to the water filler through improper placement of case.

Hoses and clamps improperly re-installed.

Check for Clearance

Determine Work Area

Step 1: Unplug the Washer

Step 2: Determine the work area, you need about 6 inches on either side of the machine, and about 36 inches in front of the machine. Clear area above the machine. If this is not available, then the machine may have to be moved.

Service access to this washing machine is gained by removing the case. This process requires enough room to remove the case and replace the case. Clearance in front of the case and on the sides is required.

Remember the clearance requirements and check them carefully, the machine is very difficult to move after the case is disconnected.

Raise the Control Panel

Raise the Control Panel

Step 3: Remove the two hold down screws on the washer control panel top. Those are located on the timer top an either side on the bottom of the timer panel. Different models have slightly different access to the screws. These instructions are for top loading machines only. Some models have plastic molded end pieces on the control panel. These can be removed by pulling on the top part in a forward motion, these snap out and snap in and are not attached in any other way. Under them are the hold down screws. Still other models have the hold down screws coming in from the back and this is less common.

Step 4: Raise the control panel, it is hinged and will rotate up and toward the back. It should be rotated out of your way.

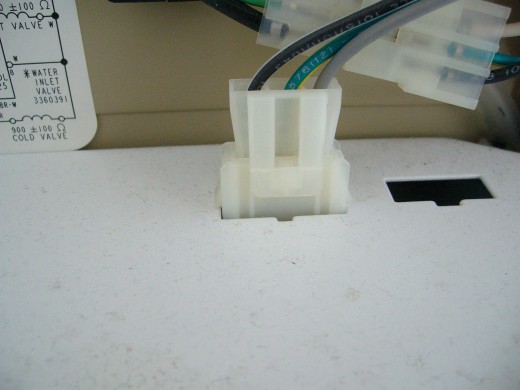

Step 5: The lid switch is connected to the control panel with a plug in wire harness. Unplug that harness found on top and in the back of the case.

Step 6: Remove the spring clips on either side of the machine. These can be removed by using a screwdriver and prying slightly on the clip. Pay attention to the placement and configuration of the clips, it is possible to replace them upside down, if you do that, you will have considerable difficulty removing them.

Remove the Case

Step 7: The case can be removed by tilting forward and lifting slightly. Move the case out of the way.

Pay attention to how the case connects to the base. This is important to the reassembly process. Notice the tabs on the base, and the slots in the case. These have to be matched up in order to reassemble the machine.

Also, pay attention to the front of the case and how it slides under a lip on the base in a tilted position. This lip must be positioned correctly for reassembly.

Notice the water fill device found at the top and rear of the case. This plastic filler can be easily damaged especially in the reassembly process.

Once the case is disconnected from the base, it can be easily damaged, move it by opening the lid enough to place your hand in the opening and lift from the front by tilting back. Move the case to a level position. Do not stack items on it, or lean on it, too much weight or pressure from the side may cause severe damage to the case. Take your time and make sure the case is in a safe secure position.

- What kind of Washing Machine should I buy?

In order to pick the best brand and type or washing machine, you need to take a variety of things into consideration. How often do you use the washer? Do you open the washer often during the cycle? Are... - Does it cost more to run a washer and dryer at the same time? How can you save on your energy bill?

There are several reasons why an electrical appliance may cost more to operate at one time as opposed to another time. Many electric providers have rates available for different times of the day. During... - DoItYourself Washer Repair Made Easy: No Spin

Click on Safety to review and follow safety precautions. Washing machines all have a lid or door device that either locks the lid or door in place during the spin cycle or stops the spin cycle if the lid... - How to use a multi meter or Volt Ohm Meter (VOM) to easy Do It Yourself Repair

What is the difference between resistance and continuity? Resistance is, in nontechnical terms anything that prevents the free flow of electricity through a device, wire, switch, splice, etc. For an...