Biogas Production of Renewable Natural Gas is Now Cheaper Than Fossil Fuel Natural Gas

Introduction

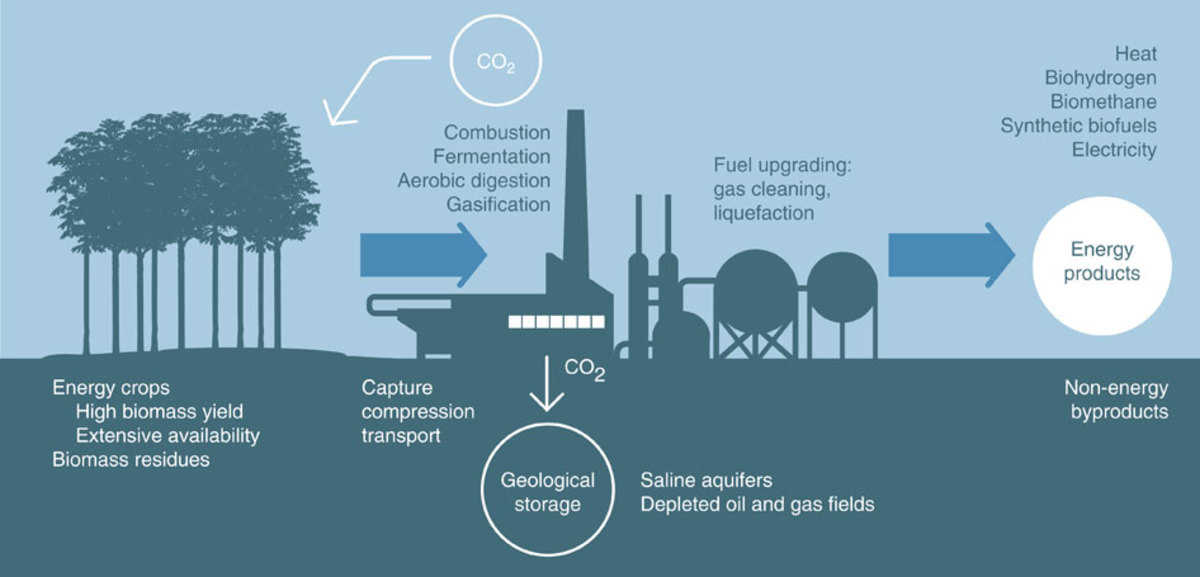

Biogas producing "digesters" are part of the new technology of Anaerobic Digestion which is rapidly being developed and will help to lower greenhouse gas emissions, and also reduce the severity of climate change.

It will provide us with transport fuels, and raw materials to make plastics etc. even after oil reserves become depleted and fossil fuels become too expensive to use for this purpose.

But, until the recent steep rise in natural gas (non-renewable gas) prices from 2021 onwards the renewable energy produced wasn't cheap.

Now it is, both due to technological advances in biogas digesters and the rise in traditional gas prices.

So the race is on for more farms to build digesters and for household food waste to be collected and digested to make a lot more "green" energy from biogas, and this is what this hub page is all about.

If you are worried about gas prices and have not yet heard of anaerobic digestion to produce methane for fuel (known as biomethane or renewable natural gas), then read this article.

Who knows, you may even find that you have a business which can benefit from having its own digester, as many are discovering right now!

Want to Really Know What is Anaerobic Digestion? Watch this 5 Minute Video to Find Out!

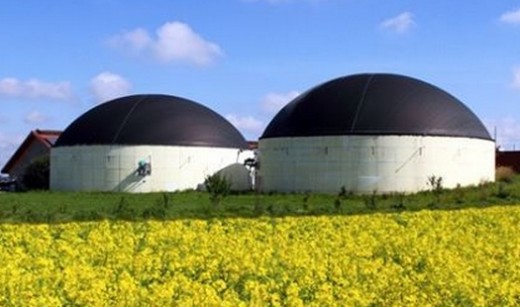

A Modern Anaerobic Digestion Plant

Background

A very popular idea currently gaining publicity is a very old concept known as Anaerobic Digestion: in which the "biogas digester" produces an energy source in the form of biogas (mostly methane).

One example is farm biogas schemes which make biogas from manure. The methane given off during the decomposition of the manure is captured and burned, providing either heat or power, for electrical generation. These promise a minor revolution in small and medium scale energy generation from methane, with a scale smaller than wind turbines, but still significant in terms of national adjustments to high oil prices.

Unwarranted Criticism of an Immature Technology

The use of anaerobic digesters to create energy, and useful products simultaneously, has been criticized for being inefficient and unstable in operation.

But, this is harsh and takes no account of that the technology of anaerobic digestion has been largely ignored and not developed at all, until the run on oil prices about in the early 2000s.

When for the first time for as long as anyone can remember, the oil price exceeded the production cost for fuel produced as methane by digestion, this old process was brought back off the shelf, and only then did development work start on using modern techniques.

A Plea for Society to Give Anaerobic Digestion Technology a Chance to Mature and Improve

This is a bit like the people who criticized the motor car for being slow while the law (in the UK certainly) required all automobiles to be preceded by a man holding a flag to warn pedestrians of approaching vehicles. Well, those "new fangled" cars that nobody wanted, soon got so much better that they beat all other forms of transport for efficiency and popularity within 20 years!

In 2008 only some half a dozen, to one dozen, AD plants had been designed, constructed and commissioned in the UK. These should be considered to be a first generation of a new breed of reactors using this technology, and there is huge potential to improve AD Plant designs. Now, in 2014 there are about 130 anaerobic digestion/ biogas plants in operation in the UK.

This is still only scratching the surface of the number of anaerobic digestion plants that can be developed from existing feedstock sources.

Tractors Can Now be Fuelled by the Biogas Made on Farms!

Developments in Biogas Digestion Systems to Produce Energy

There are many ways in which the efficiency of Anaerobic Digester bio-reactors are being improved, and the first is by using sophisticated ultrasonic technology to break up the particles and so allow breakdown of a bigger proportion of the organic content.

In some of the other processes being developed the excess liquor from the process is used to re-wet incoming biowaste as it contains useful bacterial populations. This method can produce a faster reaction then the original start-up.

It is important because on-farm Digester (Anaerobic Digestion) projects can provide needed services to farmers; develop local, renewable electrical generation; enhance environmental quality; and generate income for the community.

Other researchers have identified the fact that if you have fluctuating temperatures, then you will not be able to establish an optimum microbial population. The digester stirring system must be efficient and operational at all times to ensure that the cold, newly introduced sludge, is mixed with the warm older solids and the bacteria. This sounds easy but in a large tank with a fairly viscous sludge mass it can be surprisingly onerous on the mixing technology.

Anaerobic digestion consists of a series of reactions which are catalyzed by a mixed group of bacteria and through which organic matter is converted in a stepwise fashion to methane and carbon dioxide. Polymers such as cellulose, hemicellulose, pectin, and starch are hydrolyzed to oligomers or monomers, which are then metabolized by fermentative bacteria with the production of hydrogen (H2), carbon dioxide (CO2), and volatile organic acids such as acetate, propionate, and butyrate.

Clearly, this is a complex reaction which can be greatly improved by better knowledge gained by further academic study which can now take place given the raised awareness and importance of this technique. This will most likely yet result in big advances in how man designs and runs its new digesters.

Is Biogas Carbon Neutral? A Video Which Explains Carbon Neutrality

Increasing Use of High Efficiency Turbines for Biogas Energy

There is also potential for the methane to be burnt in efficient turbines, rather than today's ubiquitous reciprocating engines. Here the heat from turbine exhaust is used to maintain the optimum digester temperature and sustain bio-gas production.

The resultant bio-gas is collected from one such system and cleaned, then used to fire the turbines.

The results have reportedly been way above expectations, with a significant increase in production, higher yield and fewer rejects being recorded.

The digester in question is thought to qualify as a small-power production facility, which means it follows a funding schedule, enabling projects to gain rapid approval.

Providing Better Conditions for the Micro-organisms that Make Biogas

Expertise is being improved, and new products marketed, which will ensure that the micro-organisms in anaerobic digestion reactors which produce the biogas are provided with the best conditions to do their work.

These take the form of chemical additives which are designed for each biogas plant and the particular type of feedstock. One example is the additive product offered by the German Company Lukeneder, which is described in the video below.

What is the Cost of Anerbic Digestion for a Farm

Other Biogas Plant Efficiency Improvements

Improvements Which Can be Made in Developing Countries

In the developing world another angle for them is selling carbon credits from the renewable energy created by anaerobic digestion on the worldwide market. Those credits should be a source of income for as well as providing a way to readily obtain seed capital for these projects from the banks.

However, the process also produces a solid and a liquid digestate in the slurry. The use of the process would not be sustainable without an environmentally safe method of disposal, and better still preferably a 'beneficial use' of the output from digesters.

Progress in Selling the Digestate Product as Well as the Energy Output

There is certainly other evidence of progress in selling AD outputs. Another operator (Pro-Gro Mixes of Tualatin, Ore.) is thought to have contracted to market the solids material or digested fiber to the wholesale nursery and landscape industries, reportedly. It is understood to be selling between 1,000 to 3,000 yards of digested fiber, under the FiberLife brand, per month in the Willamette Valley.

But the Biggest Single Creator of Innovation is Developing AD Market and from that: Big Efficiency Improvements

The market for the digestion processing outputs is still under developed in most places. However, there are many positive signs that the work available is stimulating the creation of many new innovative companies, who's outputs will be genuinely useful in improving anaerobic digestion plant efficiency.

Some innovations are also providing new sources of additional revenue for the operators of these plants.

The adoption of manure digesters at animal operations is much more advanced in Europe than in the U.S. But, there are many successful AD plants in operation throughout the U.S.and with globalisation increasing there is now a developing AD market and with that a vibrant AD industry.

Conclusion

Digesters can be considered for a wide variety of agricultural and industrial and commercial sites. From agricultural community scale Anaerobic Digesters to supermarkets with waste food, to municipal authorities with organic waste in their collected waste streams.

There are multiple advantages to running your own biogas plant, so all businesses which produce an organic waste should now be considering the installation of a digester of one type of another.

This content is accurate and true to the best of the author’s knowledge and is not meant to substitute for formal and individualized advice from a qualified professional.

© 2008 stevelast