Manufacturing Processes and Methods Process

Manufacturing Process Selection

The selection of a manufacturing process is done very much on the basis of a manufacturer choosing the process that best suits his needs. Consideration must be given to a number of factors before deciding on a manufacturing method and 3 primary ones are quality, flexibility and cost.

Quality

This can be tricky to define, but it really refers to whether a product meets specification? A process that consistently fails to produce items that are in specification is clearly inappropriate for the task in hand. But this factor also highlights the need to get the specification right and not to over specify unnecessarily. Producing products to unnecessarily tight specifications can lead to the wrong manufacturing process being selected and will invariably lead to increased production costs.

Flexibility

Flexibility is about how easy it is to adapt the manufacturing process for required changes to the product, whether that is in terms of shape, materials or finish. A flexible process means that changes can be made relatively easily. An excellent example of a manufacturing process that is highly flexible and can be easily adapted is CNC machining.

Costs

Operating costs refer to the investment that needs to be made when setting up a process and can involve both the cost of capital equipment and labour charges. There are different ways of dealing with capital costs where they are required. Some companies (assuming you are outsourcing, not always the case) will charge for the provision of necessary capital equipment as a one off cost or in some cases the costs can be amortized over the production schedule i.e. the price per unit is made more expensive to cover capital costs.

Sometimes there are no obvious capital costs, for example a specialist vendor might be employed that has already invested in the required equipment and offer their services in producing products at a quoted price per unit. Clearly the capital purchased in order to provided the service was a capital outlay which the supplier made, so you could consider this as an amortized option in which your decision was simply whether to use that particular vendor or not.

Manufacturing Processes

Manufacturing Processes for Design Professionals - 5 Stars

Other factors that affect the selection of a manufacturing process

The selection of a manufacturing method is all about resolving problems. The problems that need to be resolved relate to the product specification and what is required from a product to ensure that it meets the required specification.

So before choosing a manufacturing process the product design specification needs to be in place. A product design specification is generally a dynamic document that may start life as an idea which needs to be converted into a salable product. Or alternatively it could be considered the skeleton upon which a full body of information can be grown in order to produce a highly detailed and well considered account of what a company needs to produce to take an idea through many development stages to become an innovative commercial product.

See the table below for a list of factors that need to be considered when creating a Product Design Specification when it is heavily influenced by marketing requirements.

Another and inextricable factor that influences the choice of a manufacturing process is the materials selection.

The physical properties of the materials either rule them into consideration for a product or conversely rule them out, this is very often done on a common sense basis in relation to the PDS requirements. Utilising a hierarchical structure, it is possible to narrow down the choice of materials, that can satisfy all requirements, to a few front runners. This statement applies equally to manufacturing process choice. Once a material that can meet specification is selected, there will be a natural culling of available processes that can be used for the material chosen.

Unique and innovative use of materials can be used to gain a relative advantage over competing products in terms of cost, performance or other factors defined in the Product Design Specification.

So the selection of material is critical both in terms of the manufacturing process chosen and the product design specification. It should not be forgotten that the manufacturing process chosen can also affect the physical properties of the material. For example a high strength steel that is supplied in bar from will be significantly different to a high strength steel that has been cast.

It is also possible that the development of new manufacturing processes may be required to realise the objectives of a product design specification. Where this is the case, it becomes as important to protect the intellectual property rights of the new process as it does the product itself.

So in summary, the manufacturing process selection criteria is very much dependent on the Product Design Specification and the material choices made, but it goes further than that. It also depends a great deal on the quantities required and the level of investment that will be needed to meet production targets

Factors to be considered for a Product Design Specification

Factor

| Comments

|

|---|---|

Performance

| What must the product be capable of?

|

Environment

| Where does it need to operate and what are the conditions under which it must meet its performance requirements e.g. temperature.

|

Target Production Cost

| An existing market will greatly influence this factor.

|

Competition

| Nature and extent of existing competition

|

Quantity & Manufacture

| Will heavily influence the type of manufacturing process and the materials chosen for the required shape

|

Materials

| Again will heavily influence the type of manufacturing process and should be chosen in order to achieve the required shape.

|

Quality & Consistency

| What are the market expectations, to fall below these expectations would be disastrous.

|

Standards

| Product should conform to existing standards unless it is strong enough to create new standards e.g. Compact Disc

|

Patents

| Be wary of infringing existing patents and consider taking out new patents to protect innovative ideas.

|

Packaging & Shipping

| Packaging needs to send the right message and should be suited to shipping options.

|

Aesthetics & Ergonomics

| Consider user interface and attraction to target consumer base.

|

Market Constraints

| Price limitations, life expectancy, likely volumes etc.

|

Company Constraints

| Does product fit business strategic objectives?

|

Technology Resources

- Materials Selection versus Manufacturing Processes

Material selections can determine what manufacturing processes are available, form can determine what materials can be used and manufacturing processes can determine what form can be created. So what you... - Manufacturing Processes - Surface Treatments

Examining and explaining the use of the manufacturing process for surface treatment of industrial components. - Manufacturing Processes - Vapour Deposition

Surface engineering processes include both chemical vapour deposition CVD and physical vapour deposition PVD - Manufacturing Processes - Joining Techniques

Adhesive bonding and mechanical fastening with rivets or nuts and bolts. - Manufacturing Processes - Friction Welding

Friction welding as it is commonly described is actually more akin to a forging process. It is typically used to join dissimilar metals or thermoplastics. - Manufacturing Processes - Brazing and Soldering

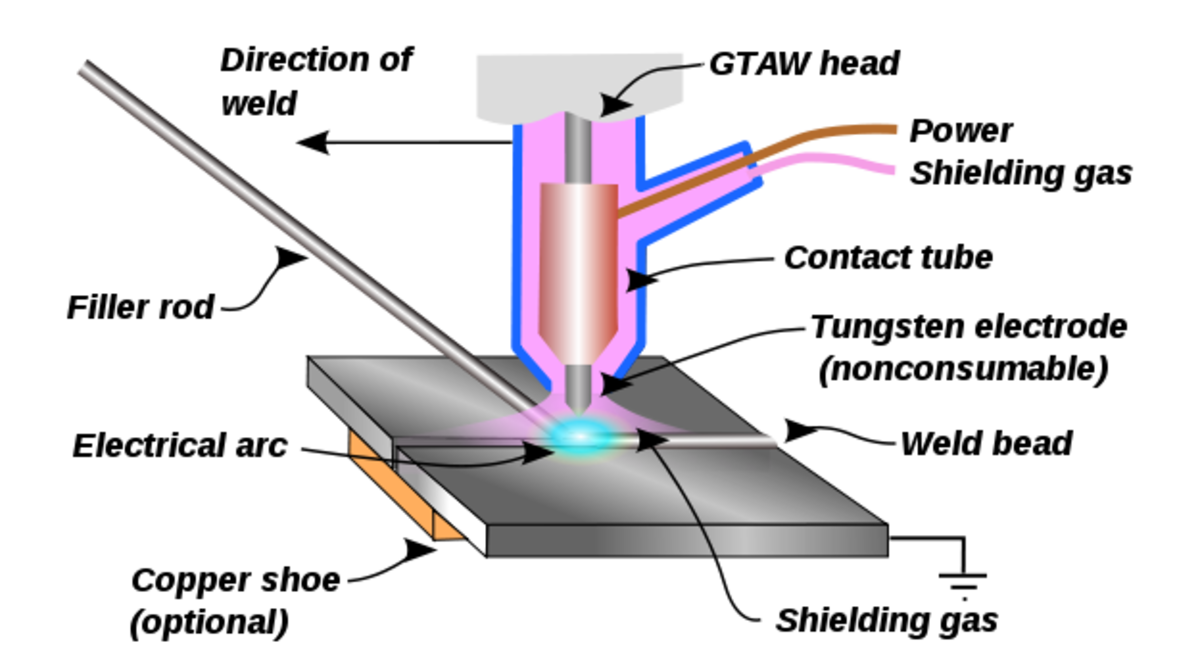

Brazing and soldering comes under the manufacturing processes category of joining. The process in both cases involves introducing a low temperature alloy into a controlled gap between metal surfaces. - Manufacturing Processes - Fusion Welding

Fusion welding belongs to the general manufacturing processes category of joining. One of the original welding techniques used was gas welding the best known of which is called Oxy- Acetylene welding. The... - Casting Process Problems

The main problem to overcome in a casting process is porosity, of which there are 2 types - Manufacturing Processes - Sand Casting

Sand casting comes under the general category of casting as a manufacturing process and is a permanent pattern process.In other words the sand moulds are produced using a reusable pattern that is removed... - Manufacturing Processes - Investment Casting

Investment casting comes under the general category of casting as a manufacturing process and uses expendable moulds and patterns.This process is sometimes referred to as the lost wax process and is one of... - Manufacturing Processes, Full Mould Evaporative Pattern Casting

Full mould casting, otherwise known as full mould evaporative pattern casting, comes under the general category of casting as a manufacturing process and is an expendable mould and pattern process.... - Manufacturing Processes - Gravity Die Casting

Gravity die casting is a simple casting process which utilises reusable metallic moulds. The process is primarily used for simple shapes with some basic coring possible. It is mostly suited to casting light... - Manufacturing Processes - Pressure Die Casting

Pressure die casting is a process that fits under the general category of casting as a manufacturing process. It utilises a permanent mould where molten metal is forced into the die cavity through a system of... - Manufacturing Processes - Squeeze casting

Squeeze casting fits in the general category of casting as a manufacturing process. Casting has been around for approximately 6000 years, so squeeze casting is a relatively new development.being introduced... - Manufacturing Process-Centrifugal Casting & Rotational Molds

Centrifugal casting fits under the general category of casting as a manufacturing process and utilities a permanent mould. Typically this process is used for the production of long, hollow components that... - Manufacturing Processes - Injection Moulding

The injection moulding process fits under the general category of casting as a manufacturing process. This may seem surprising as the process is dedicated to the production of plastic, rubber and composite... - Manufacturing Processes - Reaction Injection Moulding (RIM)

This is a permanent mould process that fits in the general category of casting as a manufacturing process and is sometimes abbreviated to the RIM Process. The general mode of operation of this process is to... - Manufacturing Processes - Single Point Cutting

Single point cutting fits in the category of machining as a manufacturing process. It involves the removal of metal from a workpiece using cutting tools that only have one primary cutting edge. Typical... - Manufacturing Processes - EDM Electrical Discharge Machining

Wire Electrical Discharge Machining fits in the category of machining as a manufacturing process. It involves removal of material from a workpiece using spark discharges. This is achieved by connecting the... - Manufacturing Processes - Grinding Machines

Grinding machines come in many different forms and types but generally fit under the category of mechanical machining as a manufacturing process. In principle all grinding machines operate in a similar... - Manufacturing Processes - Pressing and Sintering

Pressing and sintering is a powder processing process that falls in the general category of forming under the manufacturing processes umbrella.The powder is pressed in closed dies to form a green compact that... - Manufacturing Processes - Forging

The metal forging process comes under the category of forming as a manufacturing process. It involves the forming or shaping of bulk metal between dies which mirror the shape of the component or section of a... - Manufacturing Processes - Sheet Metal Forming

The sheet metal forming process comes under the category of forming as a manufacturing process. There are a number of sheet metal forming methods available which all consist of some form of deformation of the... - Manufacturing Processes - Blow Moulding

The blow moulding process fits in the general manufacturing processes category of 'forming'. A heat softened hollow plastic blank, sometimes referred to as a 'parison' is clamped between two mould halves. Air... - Manfacturing Processes - Rolling And Metal Forming

Metal rolling is manufacturing process that falls under the general category of forming. It facilitates the continuous forming of bulk metal between two rotating roller tools. It is a 2 dimensional process... - Manufacturing Processes - Superplastic Forming

Superplastic forming as the name suggests falls in the manufacturing processes category of forming. The process works under closely controlled conditions of temperature and strain rates which allow certain... - Manufacturing Processes - Extrusion Process

Extrusion fits under the general category of forming in manufacturing processes. The term applies to a variety of processes that involve confining a material in a container and applying a force to push the... - Manufacturing Processes - Vacuum Forming

The vacuum forming process comes under the general manufacturing processes category of forming. The process involves producing components that are formed by heat softening plastic sheet and forcing it against... - Statistical Process Control versus Acceptance Sampli...

There are two types of product quality control approaches that are going to be compared and contrasted in this article, namely: Acceptance Sampling Statistical Process Control. (SPC) The purpose of... - Search Engine Friendly Directory

Website Joint is a free human edited quality web directory. We provide permanent featured, regular, express and free submissions for your website. - Manufacturing Processes - Fusion Welding

Fusion welding belongs to the general manufacturing processes category of joining. One of the original welding techniques used was gas welding the best known of which is called Oxy- Acetylene welding. The... - Manufacturing Processes - Fusion Welding

Fusion welding belongs to the general manufacturing processes category of joining. One of the original welding techniques used was gas welding the best known of which is called Oxy- Acetylene welding. The...