THE TRANSPORTATION OF RUBBER BY SEA

Collection of Rubber sap

The Rubber plantation

The rubber is naturally produced from rubber trees. Originally the rubber trees were endemic to South America. The Britishers introduced the rubber trees to many other Countries such as Sri-Lanka, Malaysia, India, Thailand & Indonesia during the British colonial period.

The Rubber block

The packed Rubber blocks

The Plywood box

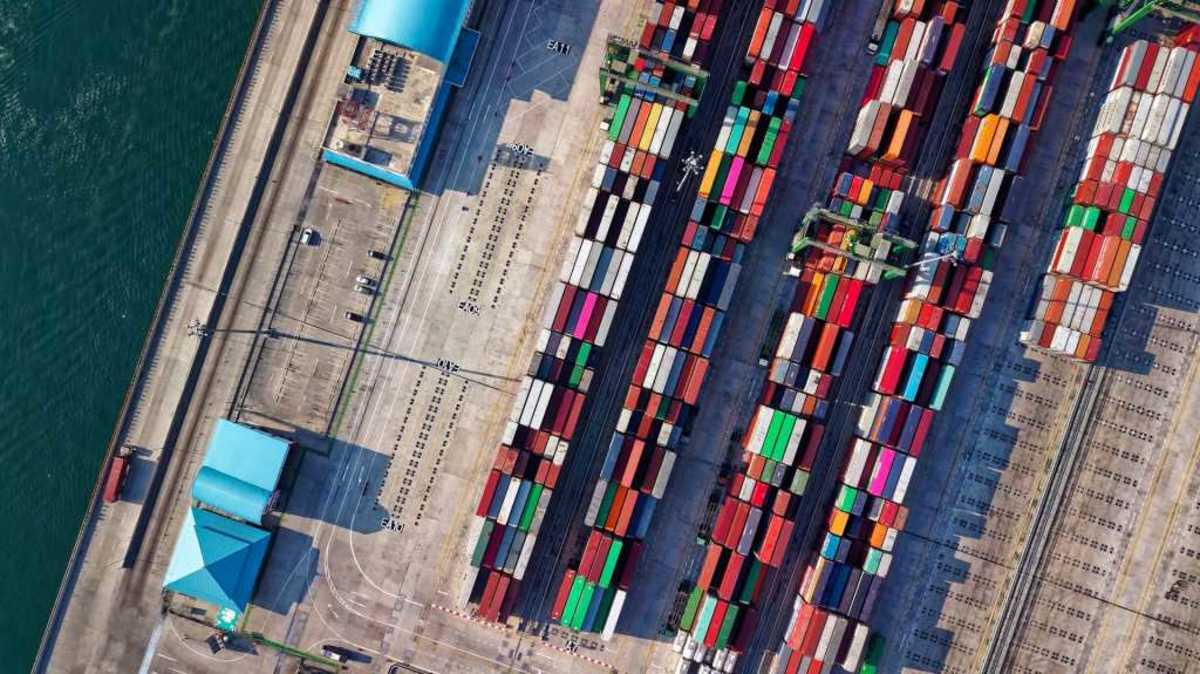

The latex (sap) is directly collected from trees & the collected latex is processed to create block rubber .Then the block rubber is wrapped with polythene & packed in the plywood boxes. These plywood boxes containing rubber blocks are transported inside containers most of the time. These containers are shipped by container vessels.

Sometimes these plywood boxes containing rubber blocks are transported by General cargo vessels. The general cargo vessels carry various cargoes. At these times special attention must be paid for rubber blocks.

The rubber blocks can be damaged by heat. The plywood boxes containing rubber should be placed well away from heat sources. Through ventilation should be carried out to avoid accumulation of heat.

Rubber can taint the edible cargoes such as tea & coffee. If these cargoes are carried with rubber they should be laced well away from rubber.

The rubber will get damaged when it comes to contact with any kind of oil (cooking oil, fuels), grease etc. Particular attention must be paid for this factor when handling rubber.

The rubber block becomes mouldy when it comes to contact with water. Especially if the Cargo sweat or ship sweat occurs it can damage the rubber. The ventilation must be carried out accordingly. The block rubber packets with mildew should be rejected.

Since the rubber blocks are transported in plywood boxes special attention must be paid for crushing. The plywood can crush very easily. The other cargoes must not be loaded on top of plywood boxes. If to be loaded proper dunnage must be used.

In some countries the labourers use Talc powder to prevent rubber sticking while carrying. The Talc should be used in limited quantities only.

Sometimes rubber is shipped in cases, bales & bags etc. Though the rubber is mostly shipped as blocks, there are situation where they are shipped as sheets & crepe. The crepe rubber is sticky & subject to cold flow. The crepe rubber is most of the time used to make shoe soles.

Finally special attention must be paid if bagged rubber is lifted by crane, thus it can slip very easily.

The rubber sheet

The General Cargo ship