How to Stain & Finish Wood- Pro Secrets Tutorial

Pro Secrets Tutorial- Staining & Finishing By Veritas Innovations

- Know your material in detail

-

Sand, Sand, Sand...

-

Pre-Treatment

-

Make Your Work Shine

Mind the details...

Getting a fine Finish is an easy thing to do, but it takes patience, and a lot of it! You have to remember that he finish is only going to turn out as good as you prepare it! A few easy evaluations will provide you with the information you need to begin your process!

Remember...

Your piece Will only turn out as good as you prepare it!

Know Your Material in Detail

What Material ar you Dealing With?

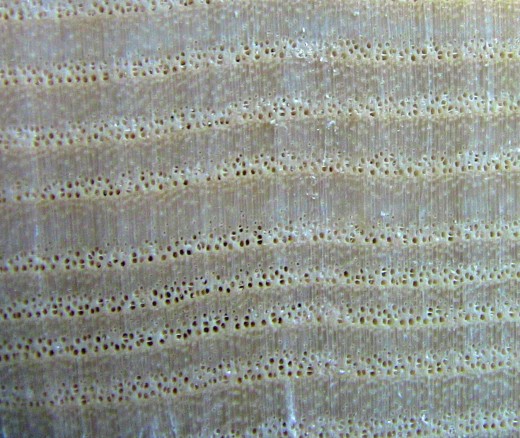

Every aspect of your finish is going to be effected by this factor. For instance, Oak is much easier to professionally finish than White Pine would be. The reason being that Oak is a much harder wood than White Pine. Its pores are smaller and much closer together, resulting in the "hardwood" label associated with it. The closer and tighter the pores are.... the harder the wood will be. In general hardwoods have very close pores which result in a tight grain structure. Close pores and tight grain usually come along with much straighter grain patterns.

White Pine on the other hand, has very loose, haphazard and separated pores which would lead us to the deduction that it is a soft wood with large pores that are further apart with a spiradic grain pattern.

To illustrate this, imagine that you had two different bundles of drinking straws. The first, a bundle of large drinking straws tied loosely with some string. The second, a bundle of coffee stirring straws cinched very tightly together with wire. As you manipulate the bundle of large straws, you note that it flexes very easily, you can't pull them apart relatively easily and when you twist the bundle the straws spread very far in all different directions and angles. This bundle displays the characteristics of soft woods, with the exception being that while the pores of the wood are relative to the straws, they are all connected and not individual units like the bundle os straws. Imagine your stack of large straws again but this time imagine that they weren't individual units and that they are connected at every point that they touch. As you twist the bundle and they spread apart in all different directions, the holes in the ends get very large , very mis-shapen and un-uniform. this represents what we call "end grain" in wood. The sides of the straws represent what we call "flat grain". This bundle displays characteristics of softwoods.

As you manipulate the bundle of coffee straws bound with wire, you immediately notice that they are heavier. When you try to flex them, they barely bend, you can barely spread them apart, and when you twist, they spread apart very little in a much more uniform pattern than the first bundle you examined. This bundle displays the characteristics of hardwoods.

Knowing the characteristics of your materials, is one of the most important steps in putting a fine finish on your product.

Hardwood vs. Softwood (Grains)

Take a Look at the Grain Difference

To the right is an example of flat grain in Oak. A Hardwood "Coffee Straw" Type Grain.

Below, you can see how much bigger, and wavy the flat grain on this White Pine is. Softwoods like this have loose, wavy and un-uniform " Large Straw " Grain Patterns.

Sand, Sand, Sand...

Now that you have pretty good understanding of hardwoods, softwoods, and their physical differences and characteristics, you may ask, " What difference does it make?".......

Simple answer......Everything!

The information that we have about our material enables us to deduce what steps need to be taken to turn a great looking product out! Considering the characteristics of hardwood, we know that the pores are very small and very close together. This means two things for our piece...

- The stain or paint will fill the pores quickly and uniformly when we get to that point. It also means that we wont have to sand as much to prepare for our stain laquer or oil, as opposed to a softwood.

- It also means that we should be able to start our sanding process with a smoother grit paper like 150 grit.

In the case of softwoods and its characteristics tells us a few things about finishing.

- The very loose and sporadic structure of the grain causes the pores to be very open and will take some prep wok in order to get it out the door looking great! When we look at a concave object like a bowl, its depth is apparent by the shadows and increased surface area as compared to looking at a plate which has very little dimension.At the same time, if you were to flatten the bowl out, it would very close to the same size as the plate in many cases! While the hardwood grain is much like the plate, the softgrains are similar to the bowl in relationship to depth. We need to close up the grain of our softwood to prevent our stain or other low viscosity product. Our sanding process is what starts closing this pourous grain. This makes a smaller entrance to the pores, and depending on the viscosity of our stain, oil, laquer, or even paint, our entry hole will allow the product to penetrate very little , or a lot! This is a monumental factor that will fluctuate the quality of finish using stains, and other low viscosity products.

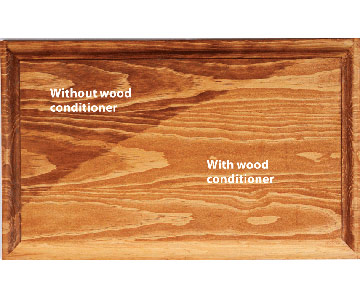

- While our goal is to close the grain as much as possible, we will also want o fill the grain, remember that softwood grain is like a bowl, and will show contrast due to depth. If you are staining ur oil rubbing, you will want to use a quality sanding sealer. This will not only raise the flat grain upwards, but it will penetrate into the wood and partially fill the pores so that penetration will be limted as far as depth, which will help to make your finish turn out with a uniform contrast instead of blotching up.To close the pores further we will use a wood conditioner, which will top of those pesky pores.

We've Settled On Varathane As Our Sanding Sealer

An Example of Yellow Pine With and Without Sealer and Conditioner

This is Our Conditioner of Choice

Sanding......

Sanding allows us to close the grain, make the piece smoother or rougher according to preference, and reveal more or less grain definition according to preference.

Sanding also directly determines how many coats of a product like laquer it will take to get a glassy finish. Typically in sandpaper choice, the higher the grit you finish at, the more definition ot "popping" grain you will have, and the fewer coats of laquer, varnish, or clear coat you will have to apply to get that silk feeling, and mirror like quality.

Like we mentioned before, we should be okay starting with, a number like 150 grit on hardwoods, where we may want to start with 80 grit paper on a softwood.

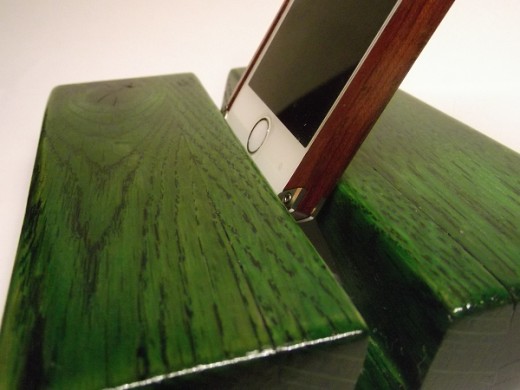

Typically , sandpaper grits comes in incremental grit jumps of 40 in lower range numbers like 40 and 80. It then advances to jumps between 20-100 as they go higher in number from, 80,100,120,150,180,220,320. From there, increments advance between 100-200 intervals. Depending on the finish quality you desire and the factors listed above that are dependent on the grit used, you can create hundreds of unique finishes. For now, we are going for a silky smooth, mirror shine finish as it is the most intense. We, at Veritas Innovations, produce the exact look, texture and shine that our clients are looking for incorporating our extensive knowledge of finishing techniques and top of the line equipment. When we're finishing one of our retail products, as opposed to a custom designed and built piece for a client, we preferr producing a silky texture with a dazzliing glass appeal! For these pieces, we usually end our sanding process at 600 grit (for hardwoods) and 800 grit (for softwoods). Most people preferr to end somewhere around 220-320 depending on their material which will produce a perfectly fine finish. Advancing above 320 grit as we do at Veritas, is for an entirely different reason. Once you get above 320 your not closing the grain, as much as you are smoothing it ou, laying the grain down to an extreme amount, and improving the clarity of the grain, which will be magnified by a quality sprayed on clear coat or epoxy, but well save that for another post...

Always sand with the grain, whether your using a block or a random orbit sander, and we would advise sanding to your desired level on the flat grain, but sanding 100 grit higher on the end grain. Think back to our straws, the length of the straws was the flat grain, and the open end of the straw was the end grain. To maintain the most uniform tone throughout your finish, sanding the end grain to a higher grit is a BIG help as the end of the board will be the most likely to soak in and be much darker than your flat grain due to all of the pores being open.

We Recommend This...If You're Looking...

Notice the difference in the pores between end grain and flat grain below

Pre-Treatment of your piece....

No matter how smooth and clean your prized piece is after your thorough sanding, sealing, and conditioning step....The reality is that it IS NOT. In fact, it could be more dirty! While you made it look so much nicer and smoother than before, there is residue from the paper and dust particles from sanding still left in the wood....In fact its been rubbed in and embedded. Getting rid of this, is a simple task but the difference in wood definition is cataclysmic after a clear coat or laquer is applied.

Water raises the grain in wood, and sfter using our sanding sealer and a good wood conditioner, we might be out of the woods........BUT were not going to chance it! Use a non water based solvent like alcohol, mineral spirits or laquer thinner and apply it generously to your piece, then wipe it bak off using a cheesecloth. Allow sufficient time for the product to fully evaporate back out of your piece and gently wipe the entire surface off with a Tack Cloth to finish.

This is the point in the process where our products get moved to a sealed,negative pressure, spray booth with filtration.

In any case, when you have completed a detailed cleaning, you will want to handle your piece with sterile gloves FROM HERE ON OUT! You have to remember that the oils in your skin WILL transfer to your piece if not protected. This especially effects stain as it cannot properly penetrate if there is any oil on the surface of your product!

For the general homeowner and a do it yourselfer, this isn't economical, but, there are some options. We would recommend making a sealed space to finish your product. The easiest and cheapest way to make this enclosure is to make a small box frame out of pvc tubing and fittings, stretch some 6 Mil Plastic over it, seal all seams of the plastic with duct tape, and cut an "L" shape about 5 feet tall and 2 ft wide as an improvised door. If you're in the garage or outside, and want to go further, you can mount a box fan in one side of the finishing booth, making sure to point it outward. If you do this, you will need filtration in the opposing side that the fan is in. Grab a good sized quality furnace or ac filter from the hardware store and mount it in the opposing wall to the fan. This will give you good filtered air ventilation in your booth at negative pressure. Just make sure to seal your door shut as you enter and leave the booth.

The controlled environment of a booth is an advantage in finishing for a few reasons:

- It protects your piece from airborne dust from the time you finish cleaning it, until the piece is finish coated and dry

- It protects your piece during and after applying your laquer, clear coat or other finish. Bugs seem to be magnetized by finish products.....

- I you've went all of the way, and included air filtration and a fan for negative air flow, your booth will ventilate itself as you spray on that fine finish. You should still use proper equipment when spraying in your booth.

- As you spray, a product, it is forced together right before the tip of the gun, and blown apart just after exiting past the tip (in HVLP spray systems) . This is known as atomization. Molecular sized particles of the product you are spraying are not seen, but they are there! The negative airflow of your booth draws clean air through the filter and the fan draws that air along with the atomized product and pushes it outside of the booth, reducing the chances of your finish being tainted by a dusting of these small (almost instantly drying) particles settling onto your perfect finish coat causing an overspray effect and hazing your finish.

- In the case you are applying a waterbourne finish product, the booth will effectively create constant clean airflow over your piece evaporating the water out of the product faster for a quicker setup time.

Depending on your product ant the technique you use, you might extract a masterpiece out of your booth after its dried.

If your going for a high end finish and have used a prouct that can be wet sanded, you may choose to cut and buff to that mirror shine!

In Conclusion...

Finishing a product properly is not hard to accomplish, but it is hard work, We hope the information provided will give you the extra bump you needed to finish your project at the highest of quality. If you think we've missed anything, or you need any further guidance or tips, we're always here for you! Feel Free to comment below or contact us directly at info@veritasinnovation.com. Were just getting started online, and are excited to teach, as well as learn from the communities that we love providing services to! We would love to see your finished product, feel free to send us a photo at photo@veritasinnovations.com so that we can feature it on our Community Finishes Page!

Give us some Feedback!

Which topic could we post about, thet would help You?

Feel Free to Rate this Post !

© 2014 Jesse Skipper