Woodworking Planes - Basic Types of Planes for Working Wood and Their Uses

Woodworking planes or hand planes are still in use by many woodworkers even with the advent of power tools of today which can do the same job faster. Often the result obtained with a woodworking plane is better and exhibits the qualities one looks for when identifying pieces of fine craftmanship.

Hand planes used for woodworking have evolved over many years. They have been found among artifacts left by the ancient Romans, and were also believed to have been used by the Egyptians in making certain furniture items. While the original concept of the plane hasn't changed much, the design was refined and greatly improved by Leonard Bailey, an American who is generally considered the inventor of the modern woodworking planes. Bailey's designs were purchased by Stanley, and incorporated into some of the most sought-after hand planes by collectors. Some of these old Stanley planes with Bailey's name engraved into them fetch several hundreds of dollars, and are no longer used as tools in favor of prized collectables.

There are many variants of the woodworking plane, but I will cover the basic parts of a plane and the basic woodworking planes that a person interested in handmade carpentry work would want in their workshop.

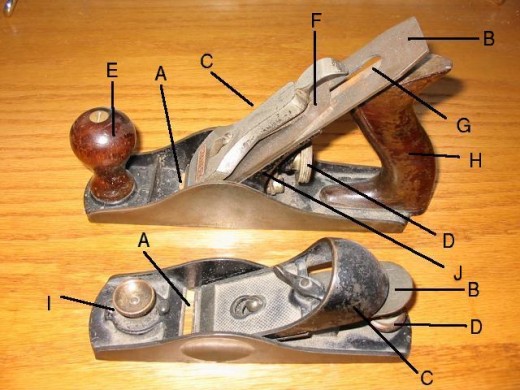

Two basic plane styles, the bench plane (top of image) and block plane (bottom of image)

Woodworking Planes Parts

A: The mouth – this is the opening on the bottom where the blade protrudes. The wood shavings also come up through the mouth.

B: The iron – this is actually tool steel, not iron, but it is the blade that actually does the work of cutting or shaping the wood.

C: The lever cap – secures the blade onto the body of the plane.

D: The depth adjustment knob – this controls the protrusion of the blade below the sole (bottom) of the plane through the mouth.

E: The knob – front handle to hold the plane securely.

F: The chipbreaker – may also be called the cap iron, it adds rigidity to the blade and forces wood shavings to break apart as they come up through the mouth.

G: The lateral adjustment lever – this moves the iron laterally in order to make a uniform depth of cut across the mouth of the plane.

H: The tote - handle in the back of the plane.

I: The finger rest knob - block planes don't require two hands like bench planes so this is where the tip of the user's index finger rests in the indentation on top of the knob. This also allows adjustment to the size of the mouth on some planes.

- J: The frog – this sliding iron wedge holds the iron at the correct angle. This is one of the advancements in modern plane design that Leonard Bailey is responsible for.

There are four major types of planes which, of course, have several variants:

The Bench Plane is a larger woodworking plane the basic parts of which are shown above with high blade angles usually around 45 degrees.

Four Types of Woodworking Planes

The Jack Plane – These are the all around woodworking planes to start a project with. They are generally found in sizes of 12” - 16” which is a good in between size for a hand plane. Primarily the jack plane is used to remove large amounts of wood. If the board is rough or uneven, then the jack plane is a logical start since it works quickly. It is not generally a finishing type of plane, although in a pinch the jack plane can be used to do the work of a jointer plane or a smoother plane.

Jointer Plane – This bench plane is used primarily to “joint” the edges of boards to make them uniform and flat so they may be joined together as in forming a wide table top without gaps between the separate boards. Jointers are typically the longest of the woodworking planes so that the long sole of the plane rides along any imperfections in the edge while the iron shaves these down uniformly.

The Lie Neilson smoother featured here is the gold standard, and while it may seem expensive, you will not find a better plane for the price.

Smoother Plane – This is another bench plane, but their primary use is on the face of a board rather than the edge. Smoothers are usually 9” -10” in length so they still benefit from riding over imperfections in the wood surface, but their shorter length make them more maneuverable. As the name implies smoother planes are used to smooth the face of a board. Usually a much finer, almost glass-like surface can be obtained by a properly sharpened and tuned woodworking plane of this type, and no further sanding or scraping would be required.

Block Plane – The block planes are smaller and have their irons set at a lower angle. They are commonly used to smooth end grain on boards, but there are many specialty versions that perform various tasks such as chamfering or curving edges, rabbeting grooves, and creating molding shapes.

If you are a woodworker looking to get back to basics or simply wanting an occasional alternative to a noisy and dusty power tool so you can finesse that piece you are working on, you really should purchase at least a good jack plane and a versatile block plane. No matter what, the job is always easier if you have the proper tool and woodworking planes are no different.

Get a set of planes together to start your woodworking off right.

Woodworking Planes Video