Motorcycle Brake Pads

Brake Pad Basics

All motorcycle brake pads are designed for one purpose; stop the bike. The concept is fairly simple and relies on the generation of friction. Friction is produced by forcing the brake pads against a rotor. When enough friction is created, the motorcycle comes to a stop. Whenever friction is created, heat and thermal breakdown will occur. This is the primary reason for creating compounds that dissipate heat well, resist thermal breakdown, and are cost effective.

Brake pads are an essential part of any motorcycle or custom chopper build, and they should be given some serious consideration. Brake pads can be made of organic, non-metallic, semi-metallic and ceramic compounds. It is crucial to understand the characteristics of these pads to best fit the application.

Three categories of brake pads will be described and compared:

- Organic and Non-Metallic brake pads

- Semi-metallic brake pads

- Ceramic brake pads

Organic and Non-Metallic Brake Pads

Non-metallic and organic brake pads are usually comprised of a mixture of carbon, Kevlar, and a binding resin. Though Asbestos has been used in the past, Kevlar has replaced Asbestos because of the health concerns surrounding it. Organic and non-metallic brake pads produce less rotor wear than metallic compounds, making them metter for chromed rotors. The trade-off is in heat dissipation. Since non-metallic and organic brake pads do not dissipate heat as well as other compounds, they are more susceptible to brake "fade." Fade describes the reduction of stopping power as the pads heat up. Organic brake pads should only be used in systems specifically designed for them.

Semi-Metallic Brake Pads

Semi-metallic brake pads (also known as metallic brake pads) are typically made of brass, copper or steel wool shavings and a binding resin. Semi-metallic brake pads dissipate heat better, thereby reducing fade, but their higher metal content produce higher rotor wear. They tend to create more brake dust and tend to be noisier than organic and ceramic counterparts.

Ceramic Brake Pads

Ceramic Brake Pads use a combination of copper strands, ceramic materials, and a binding resin. This combination of materials produces less rotor wear compared to those with steel compounds. Ceramic brake pads also have the characteristcs of superior heat dissipation and durability. noise and brake dust are reduced because of their construction. Though typically more expensive, differences in relative cost are decreasing because of increasing popularity.

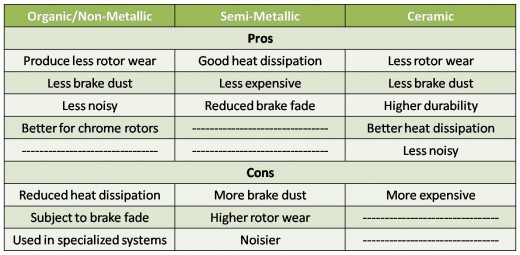

Brake Pad Quick-Comparison Chart

Reference: Chopper Fundamentals 101 © 2007