Coil Spring Design Suspension

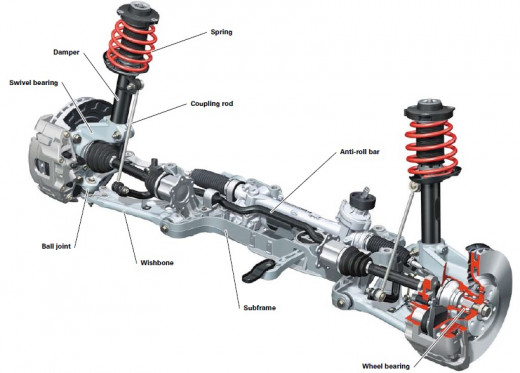

A Basic Suspension System

The suspension system And Its Function

Over the years there have been many types of spring suspension systems that have been developed, using a variety of different types spring designs and structural members, as well as different kinds of dampers/shock absorbers

.

Front suspension,obviously must deal with not only the motion of the suspension assembly caused by road irregularities, but also the steering motion. front wheel drive complicates the suspension geometry even more, because drive shafts must adjust and wheels change angles during turns.

Rear suspension can be much simpler by comparison in all but most sophisticated rear-wheel steering set ups (i.e 4x4,rear wheel drive mp-vs). the track of the rear wheels is a relative constant.

As we get deeper in spring design suspension components and how they work, remember that a vehicle in motion is more than wheels turning.

As the tyre rotates, the suspension system is in a dynamic state of balance and is continuously compensating and adjusting for changing driving conditions.

THE COMPONENTS OF THE SUSPENSION PERFORM SIX BASIC FUNCTIONS;

- Maintain correct vehicle road height

- Reduce the effect of shock forces

- Maintain correct wheel alignment (tracking)

- Support vehicle weight

- Keep the tyres in contact with the road

- Control the vehicles direction of travel

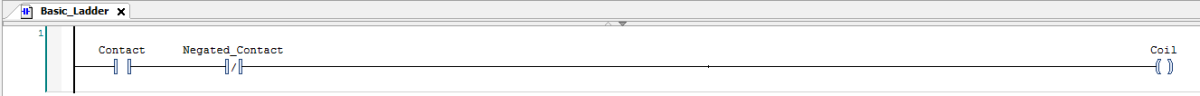

click on the link below to watch a coil spring design in motion

Suspension in Motion!

Spring Design suspension

Road springs are made from spring steel and absorb the vertical (up and down movement) shocks from road irregularities.

They are generally three types of road spring design;

- Leaf springs

- torsion bar

- Coil spring

The most simplest suspension spring is the leaf spring. These were originally used on horse drawn carts.

The modern leaf spring is made from tempered steel and may nearly flat or slightly curved.

Depending on the load being carried, it may also have a number of leaves laminated together or maybe in the form of a single leaf.

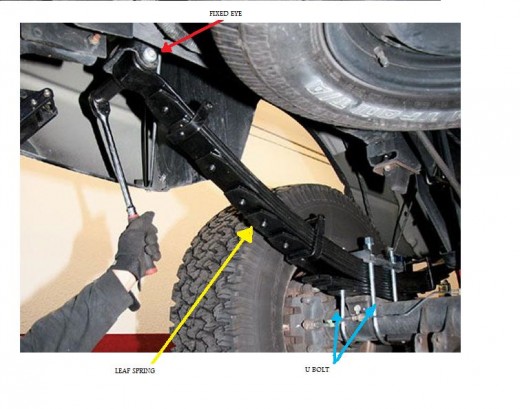

AS the leaf spring resists sideways movement it is often used to locate a one-piece back (rear) axle. the leaf spring is bolted to the vehicle at each end, and the axle is clamped near the centre with large U bolts.

One end of the leaf spring is attached directly to the chassis through a "fixed eye" whereas the other end of the leaf spring has a swinging shackle to allow the spring to alter its length when flexing.

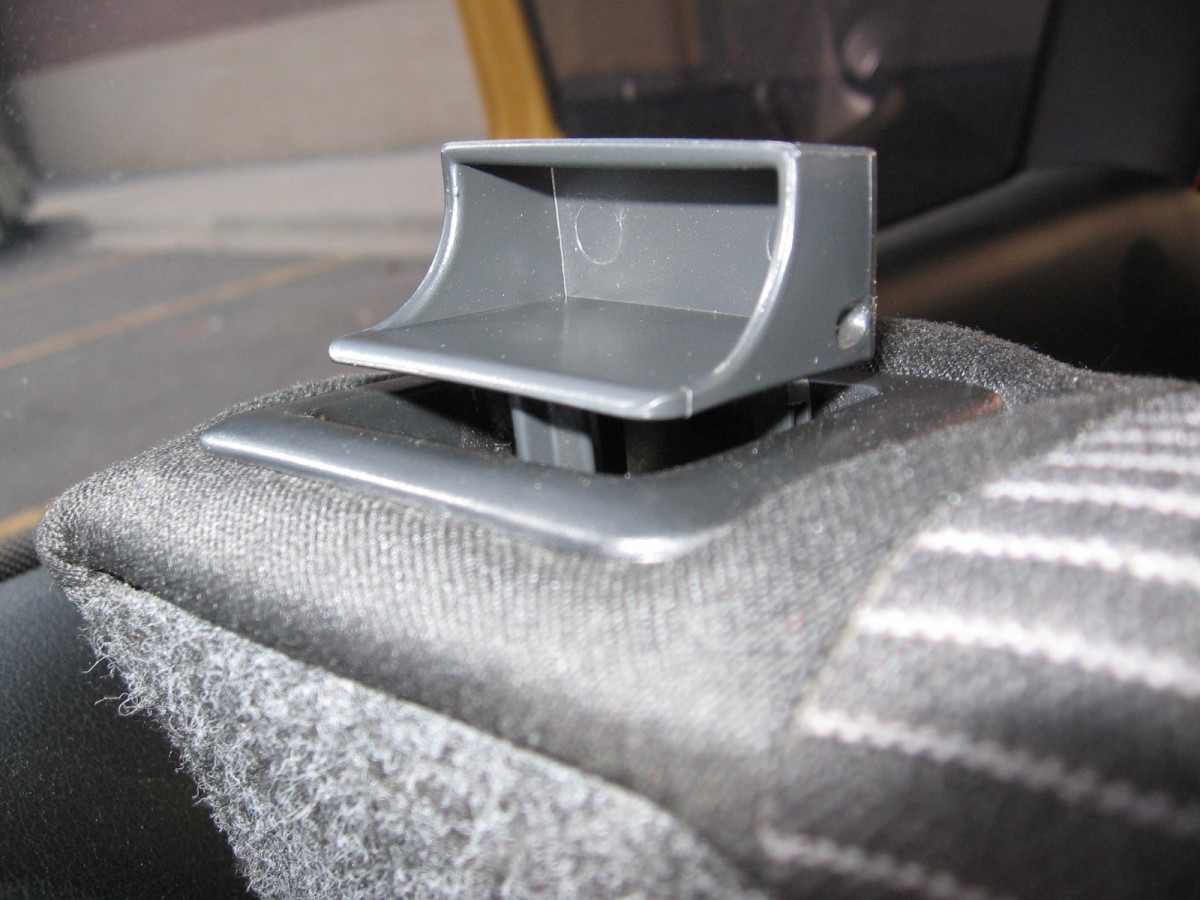

Leaf Spring and Axle

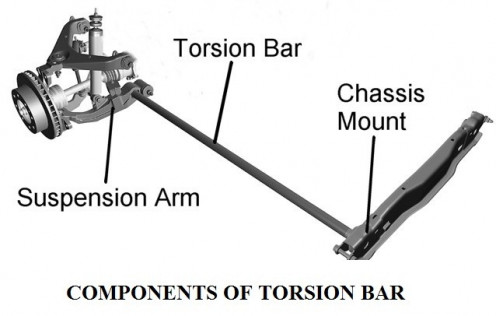

Torsion Bar

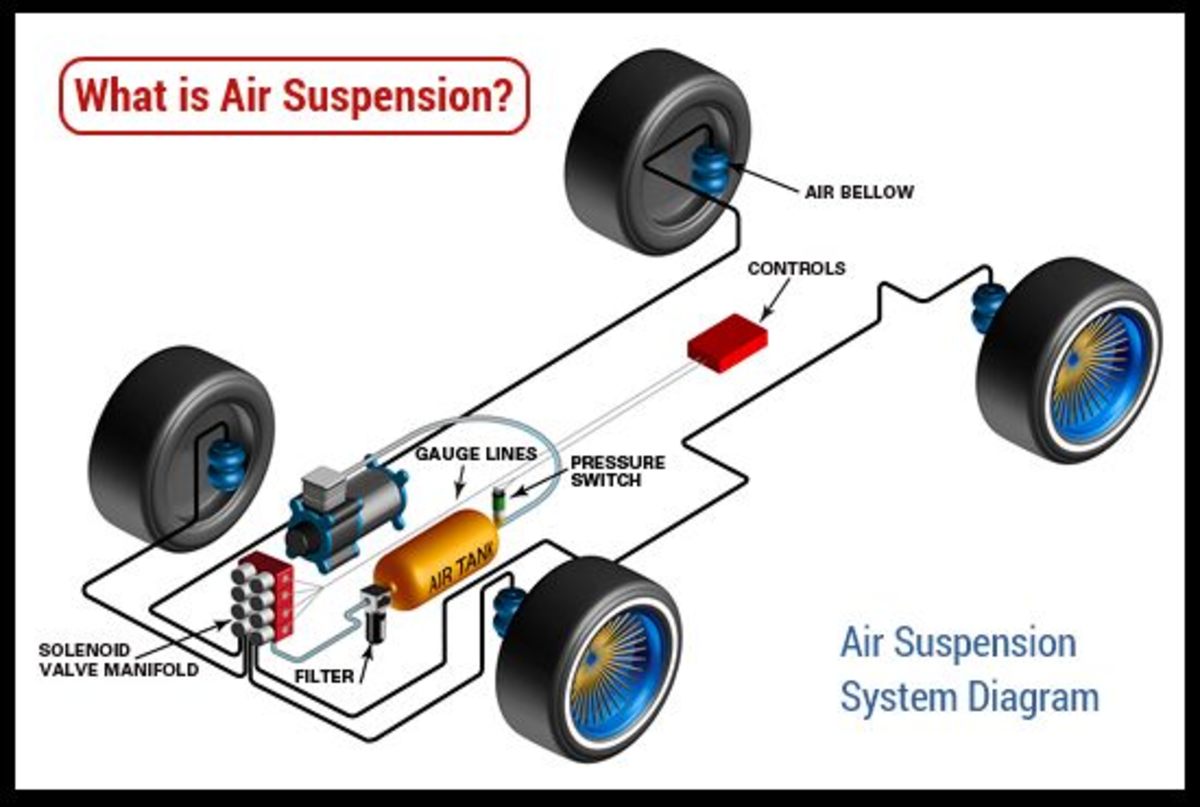

The Coil Spring Design

The coil spring design is used on the majority of vehicles because of its high capacity and compact size, in effect, a torsion bar wrapped in a spiral, and also absorbs loads by twisting the metal.

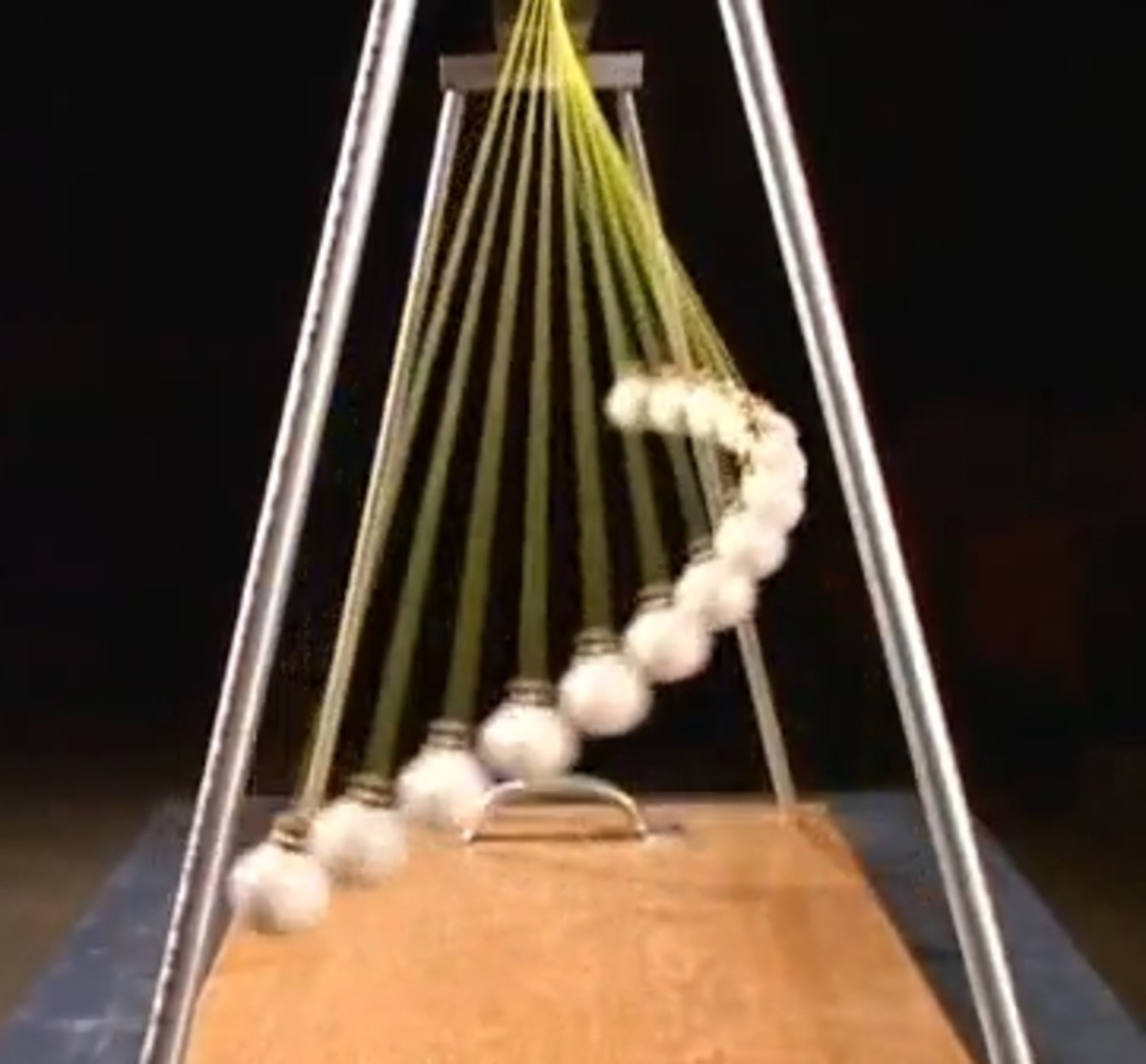

While a torsion bar stores energy when twisted, the coil spring does the same with an up and down movement(vertical). It has been found that the most efficient energy storing shape for a given weight of spring is circular and that the coil spring is the best of the three types of spring.

If the vehicle is over loaded the coil spring can become so compressed that the coils start to contact each other, this is called COIL BOUND or COIL CLASH.

Used on their own, coil springs would allow the body of the vehicle to bounce uncontrollably over an undulating (bumpy) road; therefor the majority of the suspension systems are fitted with dampers (shock absorbers)to control the spring movement.

every coil spring is different in size and possibly shape depending on the vehicle its fitted to.

it has now become popular to adjust coil springs to adapt the ride height and handling of a vehicle. This can make a vehicle look better and handle better due to being lowered to the ground but also it could wear out other suspension components that are put under further stress because of this , research properly before lowering you vehicle .

to find out about accurate parts for your vehicle at good prices

click HERE

Coil Spring on a Vehicle