Installing Shock Absorbers, Suspension Systems-the Do's and Don'ts

The Right Shock absorber

The Basic Principles

There are a lot of different methods used in every garage these days for removing and fitting shock absorbers and i have seen a few of them, air guns been used, heavy grips, wrong sized sockets, yet still not many places even today fit shocks correctly.

Its not hard and only takes that extra 10 mins to do a perfect job not a bodge job.

The following basic principles must be checked and identified before fitting shock absorbers.

- Make sure that the correct replacement units are available before removal (sometimes this can be difficult to make sure they are the correct units, just have a good visual look at both old and new units) but it is important that you identify the similarities between both new and old units as some may look the same but maybe slightly different.

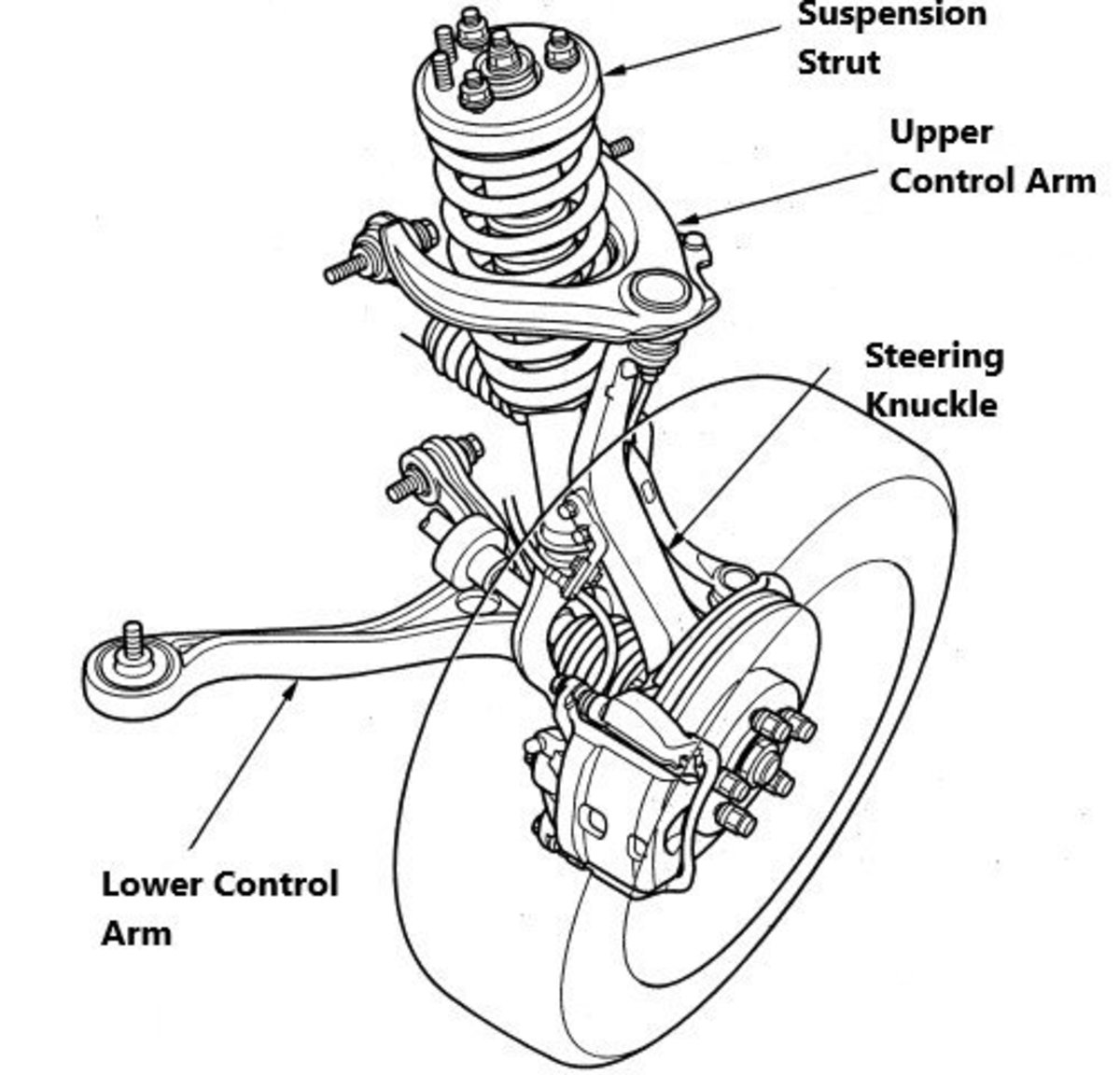

- Mark the position of the upper and lower mountings in relation to the vehicle body and other suspension components before removing semi-strut and McPherson strut assemblies (this prevents future camber or tyre wear issues).

NO air Impact guns

New Battery Powered Torque Gun

Milwaukee Impact Wrench

with the motor industry changing there is a lot more battery powered impact tools being used to make it easier and faster, however although air impact guns I wouldn't recommend I have experience and recommend a safer impact type of gun that deliverers certain torque setting to allow better removal and fitting of parts on vehicle with confidence

click below to find out how much you can save to invest in one...

Air Guns / Correct Tools

Depending on weather you are working in a garage where you have compressors with air lines of if you are in your garage at home or driveway but have a smaller compressor recommend you use only hand tools (unless removing wheel nuts these can be over tightened but always put them back on by hand and tighten with torque wrench, most vehicles usually have a torque of 100-120 newton meters).

Using them is a NO, also when removing or refitting shock absorer piston rod devices, This can spin the piston rod which overheats causing damages to the seal.

It can also loosen the piston retaining nut inside the shock absorber unit, causing the shock absorbers to knock.

tightening the mounting nuts/bolts with an air gun during installation can seriously damage the mounting parts.

CORRECT USE OF TOOLS

Always use the appropriate tools safely. Never grip or damage the polished piston rod with the pliers or grips, this can leave marks on the piston, which can cause damage to the rod seal and could cause oil leakages.

The obvious is that you will need the appropriate tools which with most popular types of struts is as follows:

- An impact socket set from sizes 10mm - 21mm and a heavy duty ratchet, a 3/8 metric size would be easier but could be handy to have a 1/2 metric size if you have some tight tough nuts or bolts (on some vehicles you may need a 22 or 24mm, if you are replacing shock absorber inserts i.e Vauxhall, Peugeot or Citroen's you may need to disconnect the drive shaft in which you may need a 30,32 or even 36mm)

- A spanner set 12-21 mm (a ratchet spanner set would be easier and could save time)

- A set of Allan key torque sockets

- A ball-joint splitter and large mallet or hammer

- Penetration fluid spray/ WD-40

- A set of heavy duty lever bars

- One main importance a spring compressor or spring clamps

Priming New Shock Absorbers

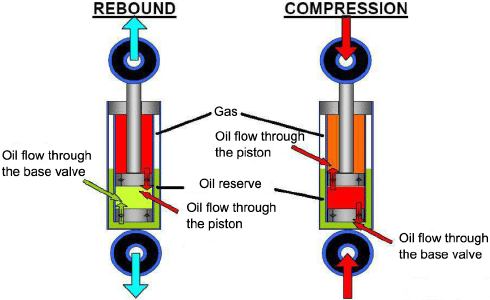

ALWAYS prime new shock absorbers, to do this you need to push down on the shock absorber (on some shocks it can be awkward so wear a thick pair of gloves). With oil based shock absorbers you wil need to pull the piston back out of the shock do this several times, if it's a gas shock, when you push down it will rise automaticlly again do this several times before installation.

Shock Absorber Inserts

Shock Absorber Inserts

When replacing a Shock absorber insert (cartridge), pour some oil in the empty strut (about 30cc) before fitting the new insert.

This oil will enable heat to be dissipated from the insert, during its operation.

Correct Fitment Procedure

Always replace missing or damaged dust shields/gaiters when you replace shock absorbers.

Telescopic shock absorber mountings and semi-strut/strut-insert piston rod nuts MUST be finally tightened or torqued when the vehicles weight is on the road wheels/ground.

Front wheels must be in the straight ahead position.

© 2011 i_rock_41