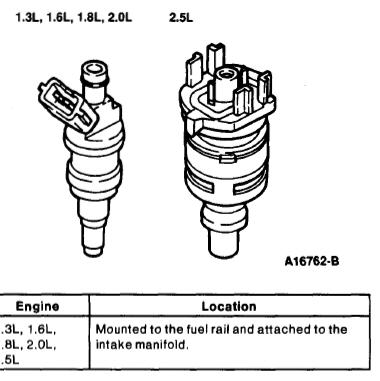

Testing for 1991-94 Mercury Capri Fuel Related Issues

The following will help determine if you need to replace a fuel pump or injector in your 1991-94 Mercury Capri car. The tests are from the Ford service manual used by their mechanics to determine if these items are causing fuel related issues, such as, hard starting, injector issues, adequate fuel pressure.

CHECK FUEL INJECTOR ELECTRICAL SIGNAL

Powertrain Control Module (PCM) Computer.

Check the electrical continuity of the injector between each injector and the PCM as

follows:

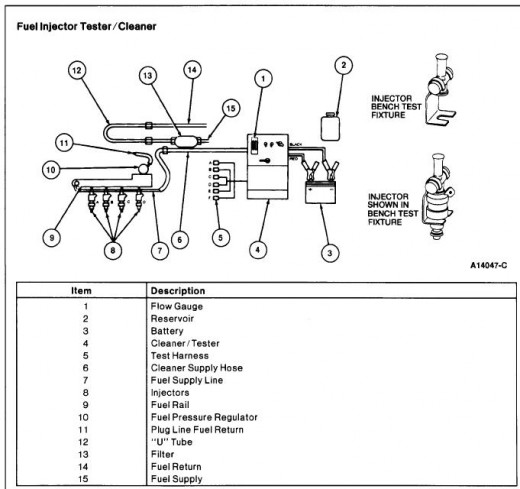

- Disconnect the fuel injector lead and insert the continuity checker from a Fuel lnjector Tester/Cleaner

- Start or crank engine.

- Observe whether the continuity checker blinks (showing a completed circuit for the injector being tested).

Repeat the check for each injector. Do all injector circuit leads show

continuity?

CHECK for 12 volts at each injector wire with key ON.

CHECK FUEL INJECTOR RESISTANCE

Disconnect the electrical connectors from the injectors. If necessary, remove the fuel

injectors to gain access to the injector terminals.

Measure the electrical resistance across the terminals of each injector.

Is the resistance of each injector approximately 12-16 ohms (20°C [68"F])?

CHECK FUEL INJECTORS (CLEANING AND LEAKAGE)

With the Fuel lnjector TesterICleaner still installed on the fuel system, note any significant pressure loss due to injector leakage when the tester pump is turned to OFF.

Check each fuel injector individually for leakage as required, using the fuel injector bench tester and the fuel injector bench testing procedure associated with the Fuel lnjector Tester1 Cleaner. Verify that each injector leakage rate is within specification ( 1 drop in 2 minutes maximum).

CHECK FUEL PRESSURE REGULATOR VALVE SEAT LEAKAGE

Observe the vacuum gauge for at least 10

seconds. Does the vacuum drop lower than 254

mm-Ha (10 in-Hal in 10 seconds?

CHECK FUEL PRESSURE REGULATOR PRESSURE LEAK DOWN

Connect the vacuum hose.

With a Fuel Pressure Tester installed, run the engine for a minimum of

30 seconds.

Stop the engine and observe the fuel pressure after 5 minutes.

Is the fuel pressure greater than 147 kPa

(21 psi) after 5 minutes?

CHECK POWER SUPPLY TO FUEL PUMP

Key OFF.

Disconnect the fuel pump connector at the fuel

pump assembly. Jump the fuel pump test terminal to ground.

Key ON.

Measure the voltage on the following wires at

the fuel pump connector.

Is the voltage between 10-14 volts?

Other test Specifications to meet

Fuel Pump Outlet Pressure (Maximum Output, Key ON, Engine Off)

1.6L 441-588 kPa (64-85 psi)

Fuel Pump Pressure (Fuel Pump Terminal Grounded, Key ON, Engine Off)

1.6L 255-289 kPa (37-42 psi)

Fuel Pump Pressure (Key ON, Engine Running, Pressure Regulator Vacuum Hose Connected)

189-231 kPa (27-34 psi)

Fuel Pump Pressure (Key ON, Engine Running, Pressure Regulator Vacuum Hose Disconnected)

1.6L 249-297 kPa (36-43 psi)

Fuel Pump Volume

1.3L, 1.6L, 1.8L, 2.0L, 2.5L 167 cc (5.5 ounces) in 10 seconds

Fuel Pump Check Valve Leakage 2 psi maximum in 3 minutes

Fuel lniector Leakaae 1 drop maximum ~ 2 minutes

Fuel Injector Resistance 12-16 ohms

Fuel Pressure Regulator Pressure Leakdown 34 kPa (5 psi) maximum in 60 seconds

Fuel Pressure Regulator Vacuum Leakage at Valve Seat 10 in-Hg maximum! 10 seconds starting with 20 in-Hg vacuum