Tips for Good Process Piping Design

Proper design of piping at the outset of any project results in good quality piping which is not only easily installed but can also be handled easily once it is installed and commissioned at plant site. In this article I have listed some important points that should be taken care of while designing a piping system.

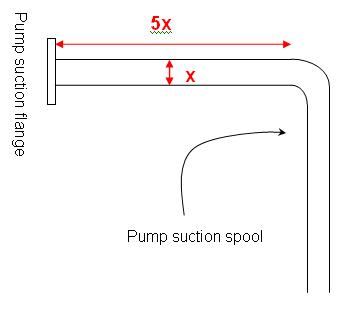

Allow straight run of at least 5 times pipe diameter before pump suction

Flow at the suction of piping must be as smooth as possible. A turbulent flow at pump suction leads to poor operation or even cavitation.

In order to reduce turbulence a straight run of pipe is necessary at pump suction and its length should be at least five times the pipe diameter.

Visualize the piping as it will be installed

A piping designer should also give consideration about how easily the piping will be installed in the field. Accessibility of piping is also an important factor to be considered. Sometimes valves need to be replaced and in some instances spools need to be removed for cleaning.

Lets consider a case which shows how good design will enable the easy handling of piping in the field.

Piping has to be installed for a pump that takes suction from a pit about 4 meters deep. Piping should go 3 meters into the pit and line size is NPS 6. The service will play a key role in selection of pipe material. Lets say service contains particles large enough to get stuck in foot valve and the suction spool is expected to be removed time and again to clean the foot valve. Service allows the use of either carbon steel or PVC. The weight per unit length and total weight of the spool is as shown in table:

Comparison of Carbon Steel and PVC pipes

Carbon Steel

| PVC

| |

|---|---|---|

Weight /unit length (kg/m)

| 28.26

| 0.0525

|

Total weight of spool (kg)

| 85

| 0.1575

|

The above figures show that installing a PVC pipe is way much better than using carbon steel pipe because of lesser weight. Pipe can be easily hauled up for cleaning if PVC is selected as pipe's material.

Pipe sleeves for underground piping

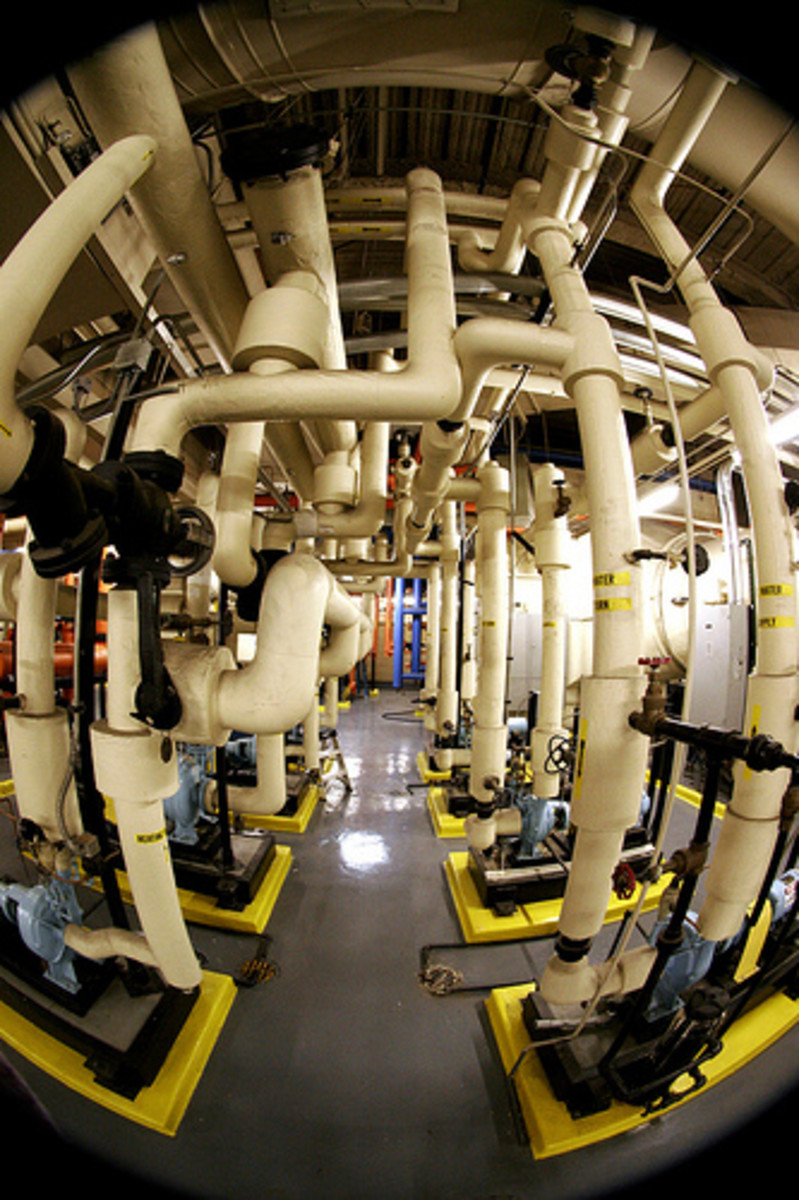

Process facilities generally have pipe racks on which piping runs. These pipe racks allow the piping to be laid out over roads as well, leaving sufficient space for vehicles to pass below. But there are instances when pipe rack is not available at a particular location or it is not feasible to use pipe rack for piping. In such cases underground piping has to be done. In process plants cranes weighing up to more than 10 tons travel on roads. This load is born by the soil under roads.

If we just dig a trench and lay the piping then every time when any heavy vehicle passes over that road, the pipe will also have to bear the load. In order to avoid any pipe leakage due to crushing load of the vehicle a pipe sleeve is used. Pipe sleeve is simply a pipe of heavy schedule pipe and its size is approximately 2 to 3" larger. This sleeve is inserted such that load is now born by the sleeve and not the pipe itself.

Provide proper supports for valves and heavy piping

Proper supports should be installed at regular intervals to prevent sag in piping. Although there are some standards that mention minimum spacing of supports between pipe runs, many a times designer's own judgement is required in placement of supports.For heavy piping e.g. pump discharge piping where NRVs and gate valves are also installed the spacing between supports can be reduced significantly. As a general rule, piping should not sag much.

Another reason for providing pipe supports is to reduce vibrations generated by rotary equipment e.g. pumps.

Don't let foundations stop your underground piping

I am not proposing that you blow out everything that comes in your (piping's) way :-)

What I am suggesting is that foundation drawings should be consulted before designing underground piping of an existing facility. In case if foundation drawings are not available sufficient space should be left around foundations to lay piping so that when soil is excavated hidden portion of foundation doesn't hinder laying of piping.