Types Of Welding

Welding is a process which involves joining of two materials using metals and thermoplastic.

There are basically three types of welding:

- Arc welding

- MIG welding

- TIC welding

These are further divided into different types.

Arc Welding

In this type of welding the concentrated heat of an electric arc is used to weld metals. A metal provided by and electrode is added to the parent metal which can be any metal using the electrical arc.

Direct or alternating current for the arc may be used depending upon the metal being welded and the electrode being used.

Arc welding is of following types:

- Electroslag welding

- Fluxed core arc welding

- Gas metal arc welding

- Plasma arc welding

- Shielded metal arc welding

- Submerged arc welding

Electroslag Welding

In this type of welding, a filler wire that forms the arc is used to make a weld metal which is deposited in the space between two metal plates that are to be joined. To enclose the pace between the plates water cooled copper dams are used.

Types Of Steel

- Types Of Steel And Uses

Steel is basically an alloy of iron and carbon with a small percentage of other metals such as nickel, chromium, aluminum, cobalt, molybdenum, tungsten etc.

Flux Cored Arc Welding

In flux cored arc welding a tubular electrode is used which is filled with flux. This flux is less brittle as compared to other coatings used in the electrodes of arc welding.

The fluxes used in this type shield the weld arc form the environment.

Gas Metal Arc Welding

Gas metal arc welding is a comparatively simpler method than the above mentioned arc welding types in which an inert gas or a combination different gases shield the welding zone and prevent any sort of oxidization in the weld puddle.

The gas metal arc welding is also very economical.

Plasma Arc Welding

In the plasma arc welding electrodes and ionized gases are used which generate and extremely hot jet of plasma on the metal plates which are supposed to be welded.

Shielded Metal Arc Welding

This method of welding is the oldest and the simplest type of welding and is also very versatile. The electrical arc in this type of welding is produced by touching the tip of the electrode with the metal plate and withdrawing quickly. Balancing and maintaining the arc during welding is very important.

To ensure a good weld, the slag formed at each turn must be removed in order to prevent accumulation oxides and nitrites.

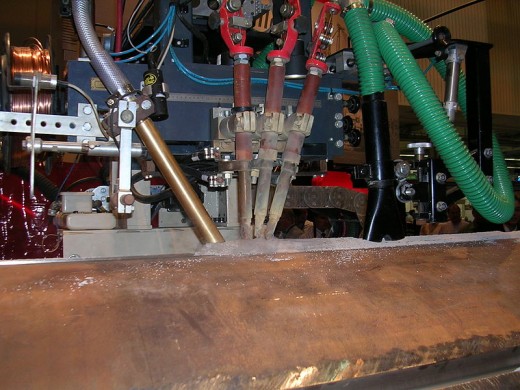

Submerged Arc Welding

In the submerged arc welding a granular flux is added into the weld zone which forms a thick layer, protecting and shielding the molten slag. This flux also prevents the sparks and acts as a thermal insulator.

The process is however restricted to the welding done in the horizontal position and is mostly used for plate steel welding in semiautomatic or automatic configurations.

Types Of Cranes

- Cranes

Crane is a huge tower to which trolleys and pulleys are attached and is used to lift extremely heavy objects. Cranes are either attached to movable vehicles or are fixed to the ground.

Types Of Building Materials

- Building Materials

Houses are a basic need for every human being. From caves to modern well built houses; houses are fulfilling the need of shelter and protection humans in every age.

MIG Welding

The MIG welding which means metal inert gas welding is a method of welding in which an aluminum alloy wire, electrode and the filler material is used.

The filler material used is a metal which is constantly added during the welding and without it the welding is not possible.

The process is also called a semi-automatic welding as all the welding parameters in type of welding are controlled by the welding machine.

In the MIG process a direct current power source is used. The positive electrode used removes the oxide layer formed on the aluminum surface.

There are two types of MIG welding:

Conventional MIG

In the conventional MIG constant power source of DC voltage current is used.

The conventional MIG has a limited range of arc current or the heat input because of which, using this process a material with a thickness of more than 4 mm can not be welded.

Pulsed MIG

In the pulsed MIG the DC power source is used at superimposed periodic pulses of high current. When the current levels are low, the arc is maintained without transferring the metal. And when the level is high the metal is sprayed during the welding.

TIG Welding

In the TIG welding or the tungsten inert gas welding a permanent electrode which is non -melting is used.

In this type of welding the filler material is added separately because of which the process is very flexible. The process can be carried without the filler material unlike the MIG.

The alternating current is used for this process. However the direct current can also be used but mostly AC is used.

Types Of Shock Absorbers

- Shock Absorbers And Its Types

Technically speaking a shock absorber can be defined as any mechanical device that on receiving a shock impulse smooths it out and converts it into kinetic energy