Fabric Dyeing.Video on Dyeing.

Jet Dyeing Machine.

Fabric Dyeing.

The fabric processing department is one of the best departments in a cotton textile mill and its also a well kept secret department from technical persons of other departments and merchants who sell the fabric in bulk and also buy from the mills in bulk.They are some how allowed inside the departments which is not in the interest of the mills.The point is if the merchants can make out what type of dyestuff the mill uses they can make out how good the color fastness will be,the other factor are many like whether the fabric is half bleached or full bleached,if it is singed or not,if it is given the proper finish including anti shrinkage treatment.The mills therefore keep visitors away from this department.

The fabric to be dyed comes to the dyeing department after it gets treated to singing,scouring and bleaching.A batch is usually in 5000 meters for one color.

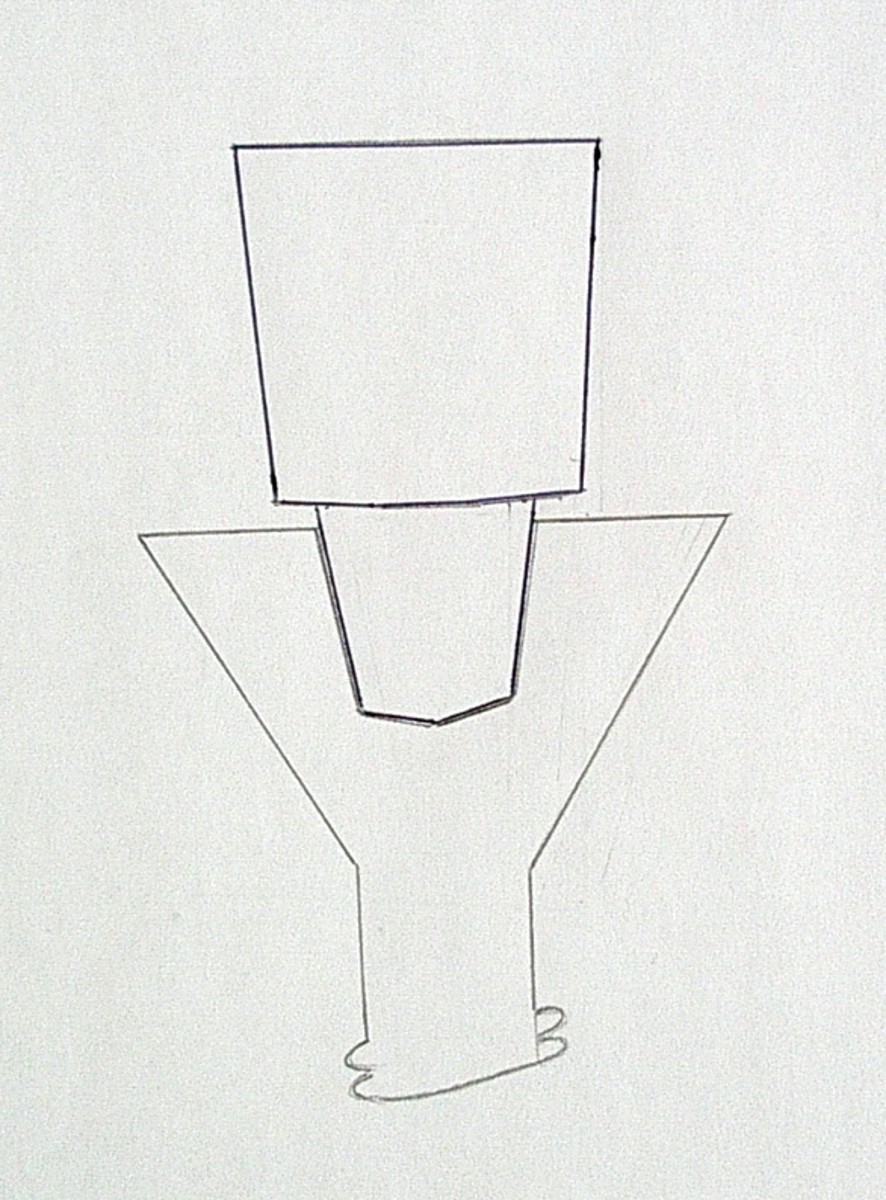

The dyestuff that is to be applied to the fabric is prepared after noting down all the colors and chemicals that are used and is always kept in stainless steel tanks with connections to the main dyeing machine and once the machine is started the process is automatic or manual as the case may be depending on the type of dyeing machine in this case its Jet dyeing and the fabric goes inside the dyeing machine in rope form and gets laid in circular formation under the machine and traverses in such a way that the entire fabric takes up all the dyestuff that is prepared.The fabric then comes out of the machine in rope form which is converted to open width.In Jigger dyeing machines the cloth in open form goes from one roller to the other in a 'V' shaped tank which contains the dye liquor at the bottom where a roller inside the dye liquor takes the cloth from one roller and the other roll winds up after certain dyestuff gets in and the process is completed rotating the cloth from one roll to other till the required shade is obtained.

The fabric then undergoes any after treatment like dye fixing agent is needed.Once this process is completed the fabric goes to Drying Machine called as Stenters which is equipped with stainless steel hot drying cylinders which drys the cloth equally on both sides as the fabric goes in zig zag path over and under these cylinders which are normally 18 to 24. The fabric also gets its width fixed to required width by use of chain of clips or pins which hold the fabric in required width.

The Cloth comming out of the Stenter goes for final finishing like Sanforizing or anti crease resistance treatment.This process is carried out for all apperal fabrics.

The final stage is marking of textile mills name and quality particulors of the fabric and packing in roll form or in folded form depending on the quality of the fabric.

The folded fabrics are packed in Bale form and again markings are made over the Bales to identify the information required.