Increase Profit through waste reduction

Increase Profit through Waste Elimination

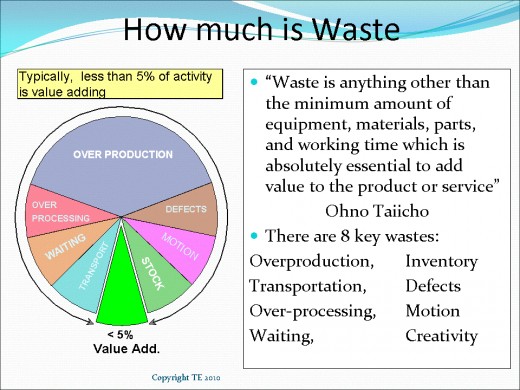

Increase profit through waste reduction if you want to make your business grow, not just follow the rest of the flock and outsource important aspects of your business overseas. If I told you that only 5% of your peoples time was spent on doing something that your customer was paying you to do you would probably tell me that I was speaking rubbish! But this is exactly what most studies show, around 95% of our time is spend doing non-value adding tasks. So why don't you try to increase profit through waste elimination, waste reduction or even waste prevention!

We spend the majority of our time conducting wasteful activities, moving stuff around, waiting for product or information, chasing suppliers, dealing with quality problems, trying to fix breakdowns and so on. The minority of our time is spent on actually doing something that the customer is happy to pay us for, adding value to the product or service that they want.

What difference will it make to your business if these wasteful activities can be reduced, if people spend more time doing what the customer really wants? It will very simply reduce your costs and therefore increase your profits.

Waste reduction is a major part or Lean Manufacturing, to find out more about lean have a look at what is lean manufacturing.

Only 5% of what we do Adds VALUE

Profit = Selling Price - Your Costs

Many companies work on the premise that their selling price is derived from their costs plus their profit and they maintain their profits by increasing the selling price when costs increase. This can be looked at as;

Selling Price = Your Profit + Your Costs

However as Taicii Ohno of Toyota was fond of telling people the selling price was actually fixed by the consumer. If you try to sell at a price that the consumer believes is to high they will go elsewhere and you will lose business. The only way to look at your companies profit is through the following equation;

Profit = Selling Price - Your Costs.

The selling price is set by the market, so the only way you can make or improve your profit is by reducing the costs within your business. This is why it is so important to remove the wastes from your business.

Value Add vs Non-Value Add

Value Add vs Non-Value Add

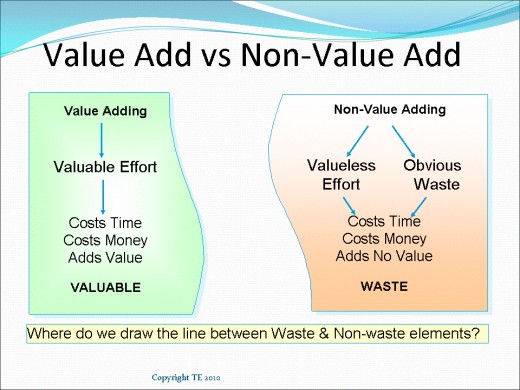

There are two parts to any work, that portion that adds value and the portion that does not, but what is “value add”?

Something adds value if it physically alters the product or service towards what the customer wants. For example; if you drill a hole in the product then that is adding value (assuming the customer wants the hole), if you then have to de-burr the hole that is a rework activity, non-value adding and therefore a waste. The customer would have expected you to use a sharp drill and have drilled a clean hole, why should he pay to have the hole “fixed” after the original operation?

So if you think about it, you are paying for every non-value adding activity in your company, the cost of each comes directly out of your profit. Each non-value adding operation you can eliminate will add to your profit.

Non-Value adding operations are waste! Something is only adding value if; it meets an explicit customer requirement and cannot be shown to be performed more economically. Implementing Lean Manufacturing can help you to reduce or eliminate these wastes.

Seven Wastes

Click thumbnail to view full-size

Reduce Cost by Removing the Seven Wastes

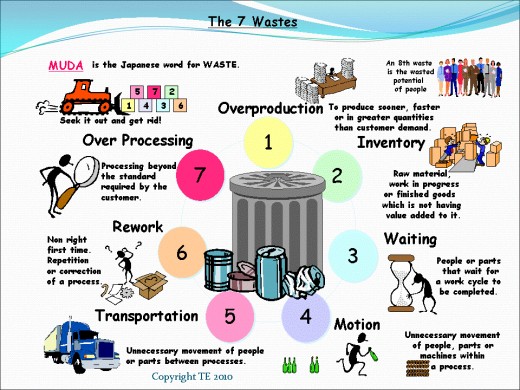

One of the Major principles of lean manufacturing is about reducing or eliminating waste. Waste is generally classified as being one of the Seven Wastes, most people when you talk about waste only consider the scrap that gets thrown in the scrap bin, but waste is much more than this;

The Seven Wastes:

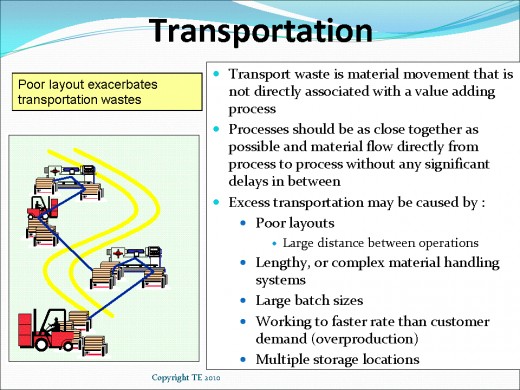

Transportation; The movement of product between different operations and locations. Required due to the production of large batches requiring fork trucks and the like to move it within the factory, made worse by the tendency to organize the factory floor into functional silos (machining, moulding, assembly, painting, etc.)

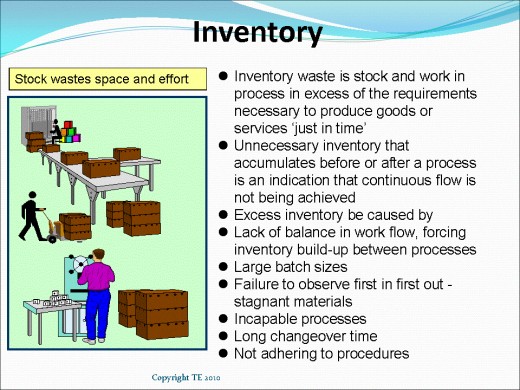

Inventory: The usually vast amounts of material held as both finished product and work in progress (wip), driven by traditional manufacturing’s tendency to run large batches to make machines more efficient and to insulate against problems.

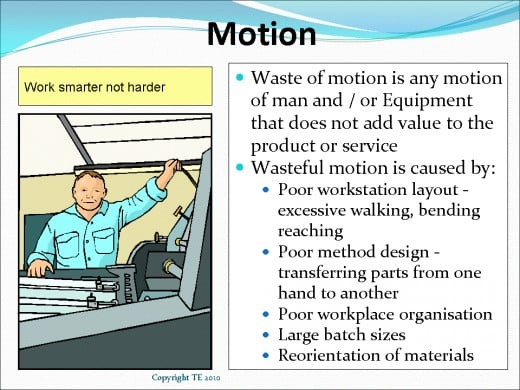

Motion; The unnecessary movement of man or machine, for instance picking up heavy items at floor level to bring to a workable height or machines that have to travel excessive distances before actual work is undertaken.

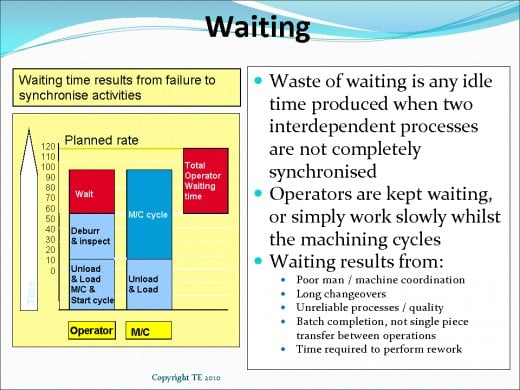

Waiting; People or machines sat idle waiting for previous operations, material delivery, information, problems to be solved and a host of other potential reasons!

Overproduction; The tendency to make product that the customer does not want or before the customer wants it leading to large amounts of Inventory.

Over-Processing; Doing work that the customer does not need, such as polishing surfaces that are never seen, specifying excessively tight tolerances etc.

Defects; The products that are created incorrectly, leading to rework, scrap, delays, paperwork, investigations etc.

A useful way to remember these wastes is the useful mnemonic TIM WOOD, Transport, Inventory, Motion, Waiting, Overproduction, Over-processing, Defects.

An Alternative is WORM PIT, Waiting, Overproduction, Rejects, Motion, Processing, Inventory, Transport.

Implementing Lean Manufacturing is the most efficient way to start to reduce and eliminate wastes in your production processes and even your office processes.

Where do we want to go?

Using Process Mapping to Reduce Costs

A full guide to simplifying work and reducing costs using process mapping can be viewed by reading; Using Process Mapping to Simplify Work.

Eliminate and Reduce Waste To Increase Profit

Once you know what the seven wastes are you can start to identify them and find ways to eliminate it to save yourself money. The easiest way to do this is to go and see what is really going on within the process you wish to focus on, never rely on what you think the process is, you are often surprised if you compare reality to what things should be!

Highlight Waste Through Process Mapping

Take a sheet of paper or a stack of “post-its”, write down each and every step of the process that you wish to review, create a simple value stream map. For example, if you were watching a simple assembly operation you could write the following, take main body from pallet (six feet away, at ground level, 100 pieces of inventory), take deburing tool from draw (operator took 20 seconds to select from other tools in the draw), de-burr six holes on body molding (40 seconds total), put de-burring tool back in draw, and so on.

Record each and every step and record important pieces of information such as time, inventory, issues – anything that seems relevant!

Once you have your process map you can begin to analyze the information, just annotate each one as to whether it is adding value or a waste, in the example above none of the things done added any value, all steps were motion or rework!

Once you have identified your waste you can try to find ways to either eliminate them completely or to minimize them, for example in the case above, bring the assembly next to the molding so that molding is passed straight to assembly not transported on a pallet in large numbers, have a simple chute to pass product directly. Maintenance on the mold to prevent the burrs, if you cant eliminate completely at least have the de-burr tool located on a shadow-board so it can be located quickly. Look at each and every waste and try to find a way to eliminate or reduce.

This should be done as a team exercise (using Kaizen principles), involve the people that run the process as well as individuals from elsewhere who may be able to bring good ideas from their areas which may be implementable in this area.

Remember, every penny, every cent that is spent on a non-value adding, wasteful step comes straight from your profit, if you can eliminate it or at least reduce it then you add to your profit, a penny saved is a penny earned! One of the biggest of focuses of lean manufacturing is that of waste elimination, learn about lean and all of its tools if you want to increase your profit and reduce costs.

If you want to learn the lean tools and methods to eliminate waste then you need to get some lean training or go out and hire a lean consultant to give you the advice and guidance that you will need.

Lean Waste Walk

Reduce 7 Wastes to increase profit

Seven Wastes Reduction to Increase Profit

Links to help Increase Profit through Waste Reduction

The following are useful links for business support and lean manufacturing resources.

http://www.ifm.eng.cam.ac.uk/ Institute for Manufacturing

http://www.thecqi.org/ Chartered Quality Institute

http://asq.org/ American Society of Quality

http://www.nam.org/ American National Association of Manufacturers

http://www.bis.gov.uk/ UK Department for Business Innovation and Skills

http://trade.gov/ International Trade Administration USA

http://www.mas.bis.gov.uk/ UK Manufacturing Advisory Service

http://www.businesslink.gov.uk/bdotg/action/home UK Business Link

http://www.business.gov/ US Business Link

http://www.smmt.co.uk Society of Motor Manufacturers and Traders

http://www.aiag.org/scriptcontent/index.cfm Automotive Industry Action Group

So if you want to increase profits through waste reduction these Links will help you to find more information regarding the Seven wastes and how to improve your business through implementing lean manufacturing and other business improvement techniques to boost your company's profits..