Is Outsourcing Overseas to China a Lean Decision?

Outsourcing overseas vs Lean Manufacturing

Is outsourcing overseas to china a lean decision, or any other country come to that? Having decided to write in the Niche of my choice relevant to my last 25 or more years of work experience I reviewed some of the other hub-pages relevant to my subject. I found a comment on a "lean manufacturing" hub that said that outsourcing overseas to India was a lean management decision, an idea that the author agreed on whilst agreeing that it was a poor one for the US economy.

Now I don't see this as a poor decision for the US economy or any of the other western economies that are outsourcing both production and services to low cost economies such as India and China, I see it as potentially devastating! I will explain my reasoning behind this in some detail shortly.

I also do not see this as a lean decision, it does not matter if you define lean as being waste reduction or if you define it as making the customer value flow at the pull of the customer, this decision violates everything about lean! So what are the alternatives to outsourcing?

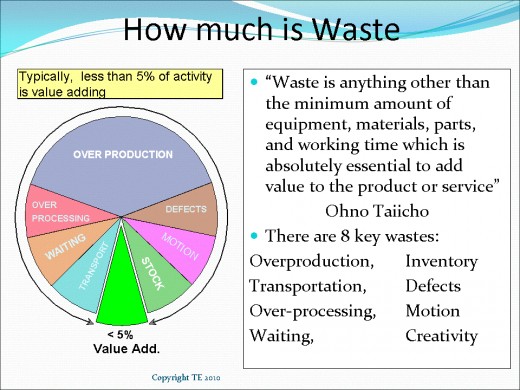

Only 5% of Actions Add Value

Ousourcing Overseas to China Vs Lean Manufacturing - A focus on Waste

Let us consider the decision to outsource against a definition of lean as being one of purely waste reduction, let us compare the reality of outsourcing against some of the seven wastes that are the focus for reduction;

Firstly the wastes of Inventory and Overproduction, the deadliest sins of lean, by subcontracting your production out to China you have to forecast your demand, you have to have an economic quantity for shipping, you have to allow for the time taken for shipping, frequencies of deliveries, potential delays due to weather, customs etc. I am sure that you can think of 101 reasons for increasing the size of the batch that will be produced and the stock that will be held locally to allow for any potential problems that may occur. The cost of this batch comes from your cash, or you have to borrow to fund it (or your supplier does, but this WILL be added to the price you pay.) Outsourcing does not reduce your inventory or reduce your batch sizes, it increases them significantly with the costs associated.

Excessive Transport Costs and Environmental Impact

The waste of Transport, a fairly obvious one, you have to transport your goods, firstly to the port, then by ship, then from the port again. This has a very significant cost, currently offset by the much reduced production cost. But how long will it be before this cost increases to the point it is more than the difference between your old manufacturing cost and the reduced one? Fuel prices are increasing, climate change levies being implemented, increased taxation, increased insurance costs etc. In addition to the costs there is the environmental impact and the social impact of the related effects, whether you agree with global warming being driven by our activity or not, you are still using up limited resources faster than we need to.

Delays and Poor Quality

The waste of waiting, waiting for your product to be delivered, delays in customs and other reasons. Waiting for decisions and actions, delays due to distance, time zones, and language differences.

The waste of defects, this is a problem that is often highlighted with supply from China, product not meeting specifications and requiring rework or replacement (more delays for the previous paragraph). I know a few engineering companies that have lost business from their main customer due to their outsourcing to china, they are now doing more business than ever doing rework and replacement parts for these same customers and others that are being supplied from China. They have found a very profitable niche for themselves! I will touch on the issues surrounding the overseas labor in the next section.

I can't think of any waste that has been reduced by outsourcing the production or service overseas, maybe someone can tell me what I am missing if they think that this is a lean decision!

China Outsourcing

Outsoucing Overseas to China Vs Lean Manufacuring - A value stream view.

In this section I shall compare the issue of lean against a more holistic view of lean, not just against a way of reducing waste.

There are three main parts to lean in my mind, Just in Time manufacturing, Respect for and involvement of your employees, and drive for continual improvement (Kaizen) towards perfection.

JIT and Outsourcing

Let us consider the decision to outsource against that of the principles of Just In Time manufacturing, the principle of creating the value that the customer wants, when they want it at the right price without it being delayed or caught up in inventory.

The delays and caught up in inventory are straight away out of the window as already discussed, we have multiplied the amount of inventory by a large factor and created many potential delays. Are we giving the customer value, in some cases not, some companies have reduced customer choice to gain the cost savings, many of the companies have lost flexibility, if the customer wants something slightly different they can no longer supply it. I know that there are some companies that have considered these possibilities and made allowances for them but they are in the minority.

Price: is the consumer really going to be happier with paying a lower price if there are other sacrifices that they have to make (more about this later). Price (or cost) is really the only reason that companies are outsourcing, either to be able to compete on cost or to increase profits (or both). The reality is that most companies if they do make savings on costs still do not pass those savings on to consumers by reducing prices.

One of the other principles of Just In Time is to get closer to your customer, hence Toyota opening plants all over the west and using local suppliers to those plants. They don't have many (if any) suppliers from one country supplying another unless the products are not available in those countries! We are moving production just about as far away as possible!

Employee Involvement and Outsourcing

Let us now consider respect and involvement of employees, this was one of the major improvements that Toyota felt was required over Ford's original production lines. Ford's management were the thinking few, whilst the workers were the muscle, not required to think, just to do the job. The workers relied very much on Ford for their income and survival at the time, but that has changed a huge amount over time, think about the hierarchy of needs! Part of Toyota's success is very much based on their people.

If the employees are low paid, poorly treated, with poor conditions they will not be best disposed to doing their best work, they will also not be looking to improve the company for which they work. As time passes in some of these countries, wages will improve, peoples perception will improve and overall things will improve for these companies, but with an associated increase in wages towards those in the west and hence an increase in costs of those products.

Now consider China, with a state controlled workforce, will they allow demand for labor and cost of living improvements drastically affect wages to the point where they are no longer an option for outsourcing? There are two ways to look at this with two different impacts, the first is, no, they keep the wages down, thus poor morale and working conditions and a workforce that will not work towards improving their products and ensuring quality. The second is one of wait; what do I mean by this, if they wait for several years it will not matter if they raise prices, once all of the skills, knowledge and equipment is there in China and lost from the west how can we start back up again? We will lack the skills and equipment to start manufacturing again, that is until the Chinese companies open plants in the US and UK to reduce their transport costs so they can reduce their costs while supplying those markets!

Continual Improvement

The continual Improvement aspect of Lean I have covered above and the subsequent need to raise conditions and moral of the workers and thus the wages and associated costs.

So did I find anything here that was slightly lean about outsourcing, I don't think that I did!

Outsourcing Cost Savings; A short Term or a Long Term View

I know that many companies have not considered the long term impact of their decision to outsource their production and services overseas. They have taken a very short term view of the cost of manufacturing overseas vs here in the west. Many have also vastly underestimated the actual costs of manufacturing overseas in the rush to follow the rest of the flock!

Consider the costs of financing extra inventory, the rapidly rising costs of transport and the associated costs, the costs of the many quality problems and delays. These have been considered in hindsight in many cases and some companies are now trying to bring back their production before they lose the skills and capability to do it!

Erosion of Cost Savings

In the long term the costs overseas, which ever country, will rise causing the savings to be eroded, it is just a matter of opinion of which will remove the savings first, the transport costs or the countries cost of living increase.

Then what, move to the next low cost economy; Africa? Maybe we should think why China is investing so heavily in Africa, is it because they see it as their next market or that they realize that it is their next competitor, so they best "own" it! Where do we go for our low cost product after that, we will be held to ransom, they can name their price if they hold on long enough!

So whether the outsourcing is a saving depends if you look at for next year, maybe 5, or if you look at the next 10, 15 or 20 years, once we hit that point it is too late! We will have Chinese companies producing throughout the west and our companies will cease to exist!

Outsourcing to China

The "Social" cost of outsourcing overseas to China.

Outsourcing our production overseas has had the effect of many thousands of people losing their employment, the associated drop in tax revenue from both the individuals and the business has led to a reduction in the availability of funds to government. Not just the loss of tax revenue of the companies that have closed or reduced in size but also those that are losing business due to the extra people becoming unemployed and the associated reduction in available disposable income!

The increased number of unemployed results in extra costs to the state, supporting these people and health care etc.

Where does the extra money come from? Savings within government? That will very simply mean putting more people out of work! So where can we get the extra money, raise the business and individuals taxes to support the extra costs; more cost to the company, goodbye to the savings they made!

Add to this the environmental aspects and fuels costs etc. the future looks very bleak if we continue down this road.

The service industry will replace this I keep hearing, but manufacturing is how we generate cash, we export we make a net gain for the country, we export we lose. Mose service industries just recycle the cash that is available in the system. We must have a manufacturing industry or a service industry that services overseas (but we are outsourcing our services too!)

What about the Customer?

The main reason for any company outsourcing is to improve its profits, they have little or No thought for the impact that their decision will have on the customer.

Any change or improvement you make should be to benefit your customers, in the long run these changes are more likely to help you grow your business!

Outsourcing Alternative

Alternatives to Outsourcing Overseas to China - Implement Lean Manufacturing

STOP outsourcing overseas, it is not the answer. It will not be a sustainable long term way to make improvements in your business. you will lose the skills, knowledge and equipment to be able to easily start again far quicker than you think!

Learn how to implement Lean Manufacturing so that you can find ways to sustainably reduce your costs whilst focusing on providing value to the customer. Most studies show that we only add value 5% of the time in our businesses, the potential savings we can make without outsourcing to China, India, etc. are huge if we look and use some common sense and ingenuity!

Outsourcing offshore to China video

Outsource overseas or find an alternative?

Should Western companies outsource overseas to cut costs or should they work harder to find ways to cut costs here in the west such as Lean Manufacturing?

Outsourcing offshore - China Manufacturing