Lean Manufacturing Consultants

What is a Lean Manufacturing Consultant

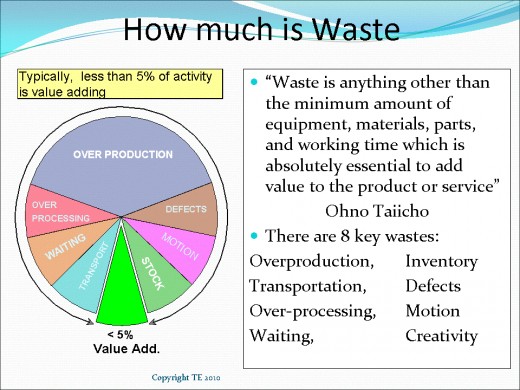

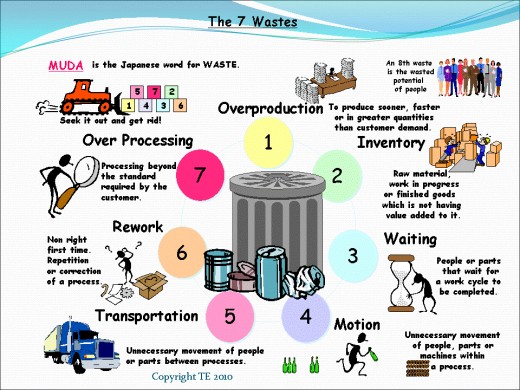

A lean Manufacturing Consultant is a business improvement specialist working with the philosophy known as Lean Manufacturing. He can help improve your business processes and implement lean systems within your company. The overall aim being to increase profit, and create flow through Just in Time principles and remove waste through identifying the seven wastes within your processes.

This Hub will discuss;

Why you need a Lean Consultant,

Where you can find a Lean Consultant

How you can Hire a Lean Consultant

How you can become a Lean Consultant

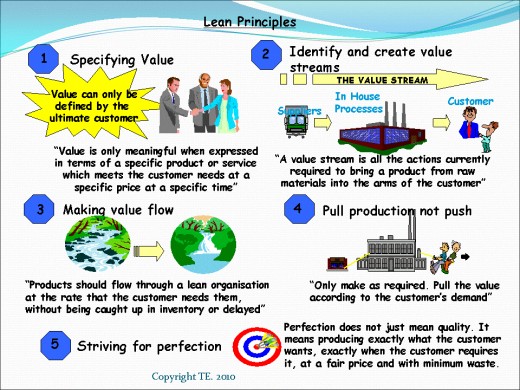

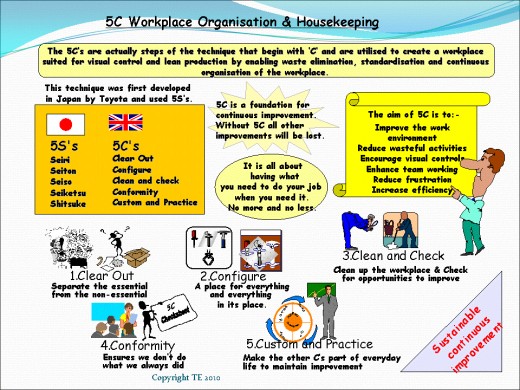

What is lean Manufacturing? Lean is both a philosophy and a collection of well proven tools that have been around for many years. The history of lean manufacturing goes back many years, but it really became what it is today when the various tools were brought together within Toyota and it became the Toyota Production System (TPS).

There are many Benefits of lean manufacturing, lean can reduce your lead times, improve your efficiencies, reduce inventory and work in progress, reduce transport requirements, improve quality, reduce floor space, improve morale, etc.. Lean Manufacturing when implemented will prevent waste (seven wastes) in your business leading to greater competitiveness, lower costs and thus higher profits.

Any good lean consultant should be able to save you at least ten times as much as you will pay them if not considerably more. I have had one client double the amount paid for consultancy because of the significant and immediate savings that were made.

Lean Consultant Images

Why do you need a Lean Manufacturing Consultant?

Lean Manufacturing Consultants are very important when discovering how to implement lean manufacturing within a company, you need to have a good understanding of the philosophies and tools behind lean, something that can be only gained through many years of implementing it. This experience is something that is difficult to accumulate and it is unlikely that if you are looking to implement lean manufacturing that you have anyone within your organization with the necessary lean skills.

Lean is not something that you can readily learn from a book or from attending a few courses within your local hotel, it requires experience and practice. Many of the Consultants around today have learned their skills within a lean organization such as Toyota and then gone off to practice their skills in other industries and companies as both employees and then consultants. Take myself for instance, I worked in three different automotive component manufacturers implementing lean for around 12 years before moving into consultancy for 2 Universities, a major commercial consultancy and then working for myself. In all I have experience of working in many hundreds of companies across many different industries!

Someone that has worked on so many improvement projects with a full understanding of the various tools available can help guide your teams through the many roadblocks that they will face when trying to improve your business. The Lean Manufacturing Consultant will also understand how to motivate and involve your employees and how to impart as much knowledge as possible.

A lean manufacturing consultant can also give an impartial and un-biased view of your business, they are not hampered by loyalties or office politics so can speak freely and make suggestions for the good of the business as a whole. They are also focused on the lean project, not the day to day problems of the business.

Benefits of Lean Manufacturing Consultants

Finding a Lean manufacturing Consultant

Searching on the internet is probably the easiest way to find a lean manufacturing consultant, a general search will tend to turn up the large national consultancies, whilst including your location or general area within your search terms may help you to find more local lean consultants.

Search also for business directories for your location in which your local manufacturing consultants may advertise, many business people have websites and businesses that are named after themselves so it is almost impossible to find them with a search unless you know in advance who they are!

Use local advice services and your local banks, also local networking groups. In this manner you will be able to both find them and hopefully also get feedback on their abilities and performance.

Lean Consultant outcomes

Hiring a Lean manufacturing Consultant

Going about hiring a lean manufacturing consultant is an area in which you need to take great care, a consultant is expensive to hire and if you get it wrong not only do you lose the money but you also run the risk of devaluing any future attempt to introduce lean manufacturing.

Hiring a lean manufacturing consultant is just like hiring any other employee, you need to create a shortlist based on the CVs, their sales pitch, background and experience. Then you need to interview them to see if they match what they have told you. Most consultants will be happy to come in for a full day to review your business and give you a detailed proposal as to what they can offer your business with an analysis of your return on the investment.

Check their references, ask them to provide a list of contacts and companies that they have worked with that they will be happy for you to talk with. If possible visit the companies to see first hand what has been implemented ans take the opportunity to talk to people at different levels in the organizations. If there are things that people feel have not gone so well of have not be sustained ask why.

Becoming a Lean Manufacturing Consultant

Becoming a lean manufacturing consultant may seem like a glamorous job, high wages, always traveling, different companies to work in, a new challenge every few weeks and so on, but the reality is often very different.

Depending on whether you are employed or self-employed can make a big difference to what you do. A lean consultant working for a large consultancy can expect a lot of travel and high stress assignments for sophisticated clients with high expectations, if you manage to get a job with one of these consultancies then you will probably spend a few years assisting before you are given responsibility for a full project. Wages are not always very high, similar to what you would earn as an equivalent employee in a large company, until you prove yourself as a lead consultant and your reputation starts bringing in clients then you can begin to earn from your bonuses..

Working for yourself as a lean manufacturing consultant is risky, especially if you only have a small amount of experience, or all of your experience is within one company that you used to work for. Getting business is a full time uphill struggle unless you have worked hard at making contacts through networking, even then you will have a big job at converting sales. The more you do the easier it will become and the higher you can charge as your experience and reputation increases. Once you have some good successes under your belt you can use this to generate sales more easily, but working on your own you will find that you will go through periods of almost no work whilst you work on filling your work pipeline and then intense periods of work during which you can do no sales work which then leaves you with an empty diary after a few months.

I found that when starting out as a lean manufacturing consultant I had to offer free time to companies to win the business, but once my foot was through the door and I had proved myself it was possible to then start to get well paid and regular projects. Once you have a regular satisfied client base you can then relax a little and work on adding just a few extra clients every year or so as the others start to reduce their reliance on you.

Lean Manufacturing Consultants

Benefits of hiring a Lean Manufacturing Consultant

Lean Manufacturing Consultant Links

The following are useful links for business support and lean manufacturing resources.

http://www.ifm.eng.cam.ac.uk/ Institute for Manufacturing

http://www.thecqi.org/ Chartered Quality Institute

http://asq.org/ American Society of Quality

http://www.nam.org/ American National Association of Manufacturers

http://www.bis.gov.uk/ UK Department for Business Innovation and Skills

http://trade.gov/ International Trade Administration USA

http://www.mas.bis.gov.uk/ UK Manufacturing Advisory Service

http://www.businesslink.gov.uk/bdotg/action/home UK Business Link

http://www.business.gov/ US Business Link

http://www.smmt.co.uk/home.cfm Society of Motor Manufacturers and Traders

http://www.aiag.org/scriptcontent/index.cfm Automotive Industry Action Group

These Links will help you to find more information regarding lean manufacturing consulting to help you improve your business by implementing lean manufacturing.