Plastics are Useful to Our Life - A Different Thought | How to use plastics in proper way ?

I am also with the view that plastics are harmful. But today I noticed an article related with this subject on internet. I would like to share it with you.

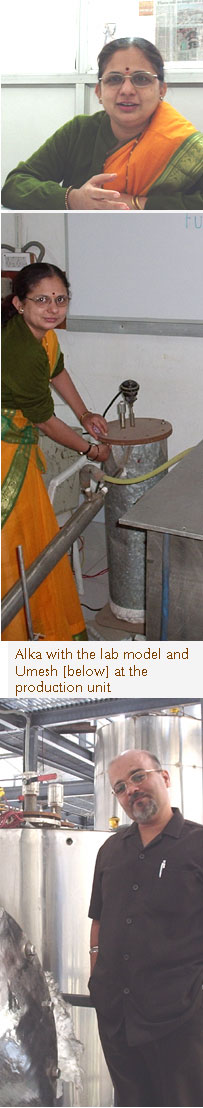

It is strange to hear Alka Zadgaonkar say, "Plastics are useful to our lives. We can't deny that."

Were she a spokeswomen for the dishonest, self-serving plastic industry lobby, that statement would be understandable. Were she a legislator we could say she was evading the issue. Her statement will likely infuriate many of us agonising over the plastic litter all around us.

But hold your breath. Alka loves plastics for an exciting reason; she is the inventor of a process that has the potential to clear our environment of plastic waste, create a million jobs in waste management, add useful, profitable products to our economy and make India a technology leader in taming plastics. Her work is breathtaking good news for this planet's environment.

Pie on the table:

We are not talking of a pie in the sky idea that is still in the laboratory. Alka and her husband Umesh, are buying in 5 tonnes of plastic waste everyday in Nagpur at prices attractive to rag pickers. They are wringing fuel oil out of that unsightly pile and selling it to industries in the Butibori Industrial Estate, on Wardha Road out of Nagpur. Production from their plant, Unique Plastic Waste Management & Research Co Pvt Ltd is sold out for the next year.

They are making money right now, and are about to scale up and buy in 25 tonnes of plastic waste a day. That production too is booked. As Nagpur generates only 35 TPD of plastic waste, they will shortly run out of raw material to grow bigger. So, a plant based on their technology may soon be playing in your town, at a factory near you.

All your questions:

Too good to be true? Let us at once address some of the questions that are already popping up in your mind. Zadgaonkar's is not a demo plant running on some government grant or subsidy. They took a commercial loan from the State Bank of India in 2005 and have already begun paying back. In fact, the government let them down and Zadgaonkars decided to flex the great Indian entrepreneurial muscle. [On that, more later.]

The process invented and patented by Alka Zadgaonkar is capable of accepting all tribes and castes of plastic waste as input: carry bags, broken buckets and chairs, PVC pipes, CDs, computer keyboards and other eWaste, the horrible, aluminized crinkly bags of the kind that pack crisps, expanded polystyrene [the abominable 'thermocole'], PET bottles- are these and others are all given equal opportunity to contribute to Zadgaonkars' profits. No sorting or picking is done.

No preparatory cleaning is necessary either, except shredding that helps economic transport of bulky waste. All solids and metal fines settle down in the melting process or are converted to ash.

Chlorinated plastics like PVC are particularly hazardous to burn because they emit dioxins. In the Alka Zadgaonkar process, the entire shredded mixture is melted at a low temperature and led to a de-gasification stage. Here chlorine is led away to harmlessly bubble through water, producing hydrochlorous acid.

Process path:

Shredded waste is continually fed into a conventional extruder. Here over the length of a heated extruder screw, the waste is plasticised and melted at a relatively low temperature. The melt is then stripped of chlorine as we just saw, and led to a reactor where lies the crux of the invention. The melt interacts with proprietory catalysts invented by Alka. The stable, continual chain of carbon found in all plastics is destabilised by a depolymerization reaction and rendered ready for a rich harvest.

Three streams of produce are obtained. A part of the gaseous cloud is condensed to form a liquid hydrocarbon. This is the recovered fuel oil. It is a sulphur free equivalent of industrial crude. It can be readily used in furnaces or put through fractional condensation to obtaine finer grades like petrol. For a long while to come, the best market for this is as furnace oil for process heating in factories. Zadgaonkar recovery plants, when they spread in the country, can use plastic from local dumps and serve local industries which currently buy expensive furnace oil from far away.

What is not condensable at the reactor is obtained as a LPG equivalent. A modified genset can generate electricity using this gas. This is now standard practice at a Zadgaonkar plant, which is self sufficient for power. The final remains are a solid fuel called petroleum coke. Approximately 70% is liquid hydrocarbon, 15% is gas and 5% is solid coke. Balance is ash and metal fines.

And now the story:

Alka born in 1962, has always had a fascination for organic chemistry. "I was intrigued by the way new products can be created by playing with carbon and hydrogen molecules," she says. "There was a sense of great control over things." That mind set was to eventually lead her to her invention.

After marriage to Umesh Zadgaonkar, she settled in Nagpur and began teaching chemistry. Umesh is an MBA and a natural entrepreneur- which means he has an ability to grab the opportunity ball and carry it over the line, eluding all tackles. He was the first to bring health clubs and gyms to a sleepy, conservative Nagpur; he realised the idea would appeal to citizens given to living the clean life. In contrast, Alka is a small, self-effacing lady fiercely committed to teaching and housekeeping. Their son Akshay is a computer prodigy.

In 1993, Alka first began to notice plastic piles in their clean and pleasant Nagpur. The menace was already a huge problem in big cities and there was a rising chorus of concern demanding solutions. These ranged from fiats to ban carry bags use [- as though other forms of plastics were innocent], to recycling to making the industry pay. "You can't wish away plastics," says Alka. "They have become a part of our lives."

She began to think of a creative solution. It was still pre-Internet days and she did not have ready to access to the state of the art. She knew her chemistry, though. She began arguing that the source of all plastics is petroleum. The trick is to revert them to their previous life where they become petroleum again. Plastics get their variety and stability from strong continual, patterned bonding of the carbon molecule. If this long chain is disrupted, they would collapse and can be coaxed to their original form. The process of disruption is random depolymerization.