Eco-friendly homes: way to a greener life

The stringent laws regarding cutting of trees and logging, and the citizens' vigilance to curb illegal harvesting of trees have dramatically affected the supply of hard wood in the world market. Consequently, prices of wood products, including those materials used in home and building construction have skyrocketed. Also, the scarcity of supply has led the wood industry to turn to the less popular construction materials.

But, no! Don't fret about the quality of these alternative sources yet.

Most often, when we think of durable building materials for homes and renovations, we tend to limit our choices on the conventional and most widely used resources, such as wood, concrete, or stone. We fail to realize that there are construction materials that are as durable, even far more cost-effective, and more sustainable than what we have known all these years. In fact, many people, especially those in the tropical region, have been using these materials for so long; and they can attest to its reliability.

The buoyant bamboo

Bamboo is one of the oldest and most environmentally friendly construction materials commonly used in regions where the plant grows abundantly, like Southeast Asia, Africa, and South America. It has been proven through research that some species of bamboo are as strong as steel, sturdier than concrete, easy to work on, and more cost-effective compared with other construction materials. It is also readily available. Because of its unique rhizome-dependent system, bamboo grows quickly up to 60 centimeters (24 inches) or more per day and reaches maturity three times faster than hard woods.

Bamboo makes a good alternative to the typical timber, which takes decades to become renewable or profitable source of building material. If you decide to use bamboo in our new housing project, or for your home renovation, you will significantly allow forests to regenerate and help reduce deforestation problem.

You can use bamboo in both external and internal applications in your home, such as:

- structural frames

- corner posts

- girders

- joists

- studs

- braces

- tie beams

- king posts

- purlins

- ridgepoles

- rafters

- sheathing

- roofing

- exterior walls

- flooring

- support columns

- electrical wire coverings

- interior walls, and many more

You may even have eco-friendly products for your kitchen and bath out of bamboo.

Trusses. A bamboo’s strength is equivalent to that of teak and sal wood.

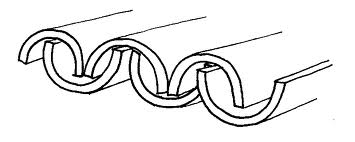

Roof covering. Long bamboo shingles make the simplest and yet durable roof covering. This is done by splitting the bamboo canes in two along their length with its diaphragms removed. They are then threaded to the ridge and arranged in Roman tile manner.

Wall and ceiling. The environmentally friendly bamboo makes a natural looking and long lasting wall cover as well as ceiling panels. Since it is light, bamboo is more suitable in earthquake prone areas because it causes less damage when it falls off. It can even be re-erected easily with less effort and at a minimum cost.

Doors and windows. Yes, bamboo door frames can be a good alternative to timber door frames; while a bamboo window blinds create a natural yet elegant look.

Flooring. Bamboo has become an increasingly popular flooring material for its better wear and tear resistance and resilience properties. Besides, it can be replaced quickly. Since bamboo is a type of grass, it takes only around 3 to 5 years to make its cane ready for flooring use, whereas timber takes 15 to 29 years before it becomes suitable for the same purpose.

Scaffoldings. Because it is light, flexible, and yet strong, bamboo is a good material for scaffoldings even in the construction of tall buildings. Besides, it is safer to use than its steel counterpart. It is so much cheaper, too.

Aside from its ability to grow quickly, bamboo offers so much more benefits both to mankind and to the environment, such as: its cultivation process does not need any fertilizer, pesticides, or much water; a grove of bamboo discharges around 35 percent more oxygen into the atmosphere compared to a similar stand of trees; it matures and can be replanted within seven years, so much shorter than the 30 to 50 years to make a stand of trees mature, and; bamboos help improve soil conditions and prevent erosion.

The cost

When it comes to costs, you can rest assured that bamboo will provide you excellent quality for a surprisingly less cost. For a basic 120-square foot area, for example, you will spend only an average of $3.86 per square foot of flooring. This includes the cost of materials and installation. If you prefer high-end quality flooring, however, expect to pay around $8.65 per square foot for the same extent of job. This features more consistent color and uniformed bamboo grain. But of course, these prices may vary, depending on your geographical location, skills level of the contractor you hire, extent of the job, and the complexity of work involved.

Coconut homes and furniture

Aside from bamboo, the coconut tree is another renewable resource that can well substitute for the conventional hard wood. In terms of durability, versatility, and sturdiness, coconut wood has proven to be as good as the conventional hard wood but at a remarkably lower cost. It makes a good material for construction and production of furniture.

People in tropical regions like the Philippines and Indonesia are familiar with homes and furniture made from different parts of the coconut tree. In fact, every other home, especially in rural areas, may be made of the cost-effective and environmentally friendly coconut timber.

Yes, it is true. The coconut tree, referred to as the ‘Tree of Life’ due to the countless benefits it provides to mankind, makes a good timber source for houses and building construction. Commonly used as trusses, joists, purlins, walls, window frames, and jalousies, the coconut trunk is a versatile material.

The center of the coconut trunk, which quality is classified as low density, can be used for non-load structures such as panels and walls. Meanwhile, the perimeter of the coconut trunk, classified as having high density, is suitable for use as joints, trusses, posts, floor tiles or parquet, purlins, floor joists, railings, girts, balustrades, and other load bearing constructions. It can even be used as posts, and power and telecommunication poles.

Medium density coconut wood, on the other hand, is suitable for horizontal studs, door frames, window frames, walling, and ceiling joists. Coconut wood is also suitable for use in grocery pallets, poultry and livestock shelter, home and office furniture, and countless novelty items.

It should be noted that as a general rule in construction, coconut lumber with density below 400 kilograms per cubic meter is not suitable – and therefore - should not be used as structural framing material. But it can be utilized as wall lining and ceiling by forming it into boards and shingles.

Due to its naturally small diameter, the coconut tree produces only a limited size of sawn lumber, generating only an optimum width of around 25 millimeters and a thickness of about 50 millimeters. Thus, glued lamination of the wood is performed to meet the requirement of larger lumber sizes. Another problem associated with the structural application of coconut wood is the difficulty of nailing, which usually results to splitting of high density wood finishes.

Nevertheless, according to some studies, there are indicators that the demand for coconut lumber is on the rise as manifested in the increasing price trend of coconut trees, and the growing number of coconut lumber producers and dealers. This is good news to the coconut-growing countries in Asia and the Pacific, where there is abundance of old and senile coconut trees that needed to be cut down. Besides, millions of coconut trees are felled annually by hurricanes that come to pass in some of the countries along these areas. Leaving these unproductive and felled trees to rot in the field would only serve as a breeding ground for beetles and other insects which could ultimately create serious infestation problems to healthy coconut trees and other crops.

It is but practical to process and add value to the old and senile as well as typhoon-felled coconut trees than to let them go to waste and pose threat to the environment. Converting these trees to profitable wood products does not only pave the way to a system of appropriate disposal but it also provides employment and additional source of income among coconut farmers and growers. Besides, utilization of coconut wood will boost the source of raw materials for the wood industry, providing cheaper but comparably durable construction materials both for housing and for export.

How much does it cost?

Currently, the demand for coconut wood in the construction sector comes in the form of scaffoldings and form lumber, the costs of which depend largely on the density, size, and on the lumber store from which you purchase your supply. In smaller cities in the Philippines, for example, the prices of coconut lumber can run around these rates:

- Size 2 x 2 x 8 = $0.80

- Size 2 x 2 x 10 = $0.90

- Size 2 x 2 x 12 = $1.08

- Size 2 x 3 x 10 = $1.34

- Size 2 x 3 x 12 = $1.62

Prices near or in metropolitan centers, however, could be higher. Nevertheless, when you compare these prices with those of conventional wood material, you will notice that coconut lumber is so much cheaper.

If the demand for coconut wood continues to rise, we will surely reduce the pressure and dependence on natural forests, and allow rehabilitation of our denuded lands.

Related Article

- Coconut Wood for Construction and Other Uses | The Catalyst

The coconut palm, which is known scientifically as Cocos nucifera, L., is one of the most important crops in the Asia-Pacific region because of its several uses, among which are for food, shelter, and fuel. In my previous posts, I mentioned about the