What is a High Vacuum ?

Science, Engineering, and Applied Technologies often require a Vacuum

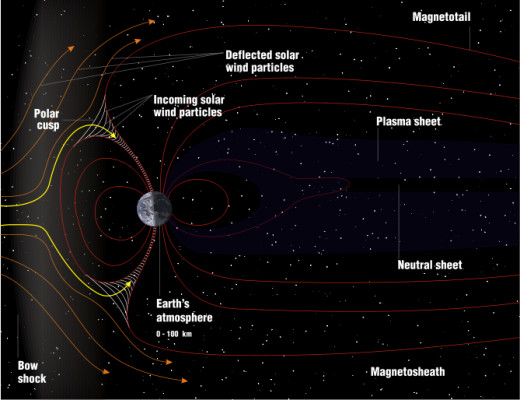

Outer-Space is not a perfect Vacuum

Particle Physics at Brookhaven National Labs

In the early 90's, I was a member of a Tech-Support Group, at Brookhaven National Labs, where I worked in direct maintenance of the nuclear particle accelerators there. In order to conduct experiments in Physics, it is essential to create chambers that have absolutely NOTHING in them, except for the subatomic particles being studied. Physicists and Engineers routinely create a vacuum for this purpose. Attaining and maintaining that vacuum as an environment in which to perform experimentation is a central concern in the running of a particle accelerator. The idea is to come as close to a "perfect vacuum" as possible.

What is a vacuum?

Vacuum refers to space that is empty of all matter. It comes from the Latin 'vacuus' meaning empty or void. If you look into the topic of science and vacuum, you see reference to the words "perfect vacuum", referring to an ideal condition for some experiments. To perform such experiments the idea is to get as close to a 'perfect vacuum' as possible. To achieve a region of space- With Nothing in it. Or, to be humorous, it is much-ado over nothing. Truly.

Vacuum is measured in terms of a unit called "Torricelli's" or "Torr" for short. Another unit of measurement is in "Pascals". Evangelista Torricelli, and Blaise Pascal are two pioneering physicists who created these fundamental units of vacuum measurement. One Atmosphere of pressure is equal to 760 Torricelli's (760 Torr) or 760 millimeters of mercury. (For greater detail, read up on Torricelli's experimentation) You may see vacuum measured in: Torr, millibars, Pascals, or inches of mercury. For engineering purposes, referencing the vacuum technology standards as applied today, there are four basic stages of vacuum achieved through various technologies. The mechanical design and dynamics of the pump dictate the pressure-range at which a pump is able to operate. So, the vacuum industry recognizes four pressure regimes 1) coarse vacuum (760 - 1 Torr [1mm of mercury]) 2) rough vacuum (1 Torr - 10E-3 Torr [see below]) 3) high vacuum (10E-4 Torr - 10E-8 Torr) 4) ultra-high vacuum (10E-9 Torr - 10E-12 Torr)

The entire dynamic range of these pressures approaches 10E-15 Torr. To achieve complete pumping from rough to ultra-high is beyond the ability of any single pump. This is known as multiple-stage vacuum pumping. Theoretically, it may be achieved in two stages, but more commonly the ultra-high vacuum is achieved with at least 3 stages. To do so one may use a 1) roughing pump 2) turbo-molecular pump and finally 3) an ion-pump

To give you some intuitive idea of a common rough-vacuum... An average household vacuum-cleaner reduces atmospheric pressure by approximately twenty percent.

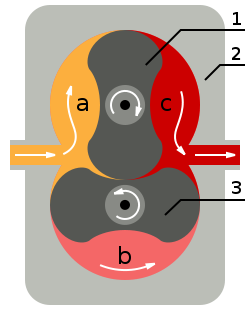

this is a piston rotary pump

Types of pumps

Vacuum pumps are divided into two basic categories. Gas transfer or gas capture. And there are all kinds of pumps. Just to list a few by name: piston, blower, compressor, cryogenic, diffusion, dry pumps, scroll pumps, turbo-molecular pumps, ion-pumps, vane pumps... and there are many different manufacturers out there. Often a pump is identified by manufacturer and type. For instance, you may see Perkin-Elmer ion-pumps, or Varian ion-pumps.

these mechanical pumps to the right, achieve a rough vacuum

With the exception of diffusion pumps, all gas-transfer pumps exhibit some form of mechanical motion- meaning they vibrate in some fashion or make noise. A simple piston-roughing-pump is quite noisy. A turbo-molecular pump, though a finer piece of engineering, makes noise also with it's extremely rapidly spinning turbo-fans. An ion-pump has ZERO moving parts and is an example of "gas-capture" and is utterly silent. What it does is bury ions within metal plates inside the device via electric potential difference of plates or cells. Ion-pumps eventually must be removed and refurbished then returned to service just as mechanical pumps do.

A pumps "ultimate pressure" is the final and maximum pressure achievable by a pump. It is determined by blanking off the pumps inlet with a pressure-gauge, then the pump is allowed to run until it achieves it's absolute, or "Ultimate" operating pressure. In reality, when attached to a chamber of any type, the real vacuums achieved are not quite as high as the pump, pulling a vacuum upon itself alone.

The practice with vacuum technology, when attempting to achieve a "clean" vacuum is to pump-down the pressure in stages. A vacuum stage is achieved, then maintained for a time period. This allows the pumps to exhaust volatile chemicals that "boil off" from interior surfaces of the chambers, and all vacuum plumbing involved. If an accelerator tube has been at atmospheric pressure, and is filled with air, there is a substantial amount of water and oils to remove from the surfaces or gases within. Then, with the passage of time, eventually after the volatiles have boiled off as much as possible at this particular pressure, and the pressure drops to it's lowest, and stabilizes... Then the next stage of vacuum pumps are brought online.

Often, equipment like nuclear particle acceleration chambers are maintained at vacuum, -at least a low-vacuum, sometimes high-vacuum, at all times possible. This keeps them "clean". Maintaining equipment at a low-vacuum, allows you to much more rapidly achieve a high vacuum, upon demand, and bringing the high-vac pumps online. Or, once a high vacuum is achieved, and if your equipment is not leaky, it is very easy to keep it all at high vac, by leaving a few ion-pumps quietly running. And when time comes to "work", you bring more ion pumps online, and the cryogenic pumps also, to achieve an ever-higher ultra-high vac, and then go to work bringing magnets online, establishing fields, and then fire up the beam, injecting a few particles of your choice.

up above a little way, you see two examples of mechanical pumps. With these you can pull a rough vacuum to as high as 10E-3 Torr, approximately. There are ways of getting a higher vacuum from these mechanical pumps, but they often have an oil inside them that will "out-gas" at pressure. So they quickly limit themselves with an organic-chemical (volatile chemicals) ceiling. Why fight for a point or two when there is another type of gas-transfer (mechanical) pump that does the job very nicely

Turbo-Molecular pumps to the rescue

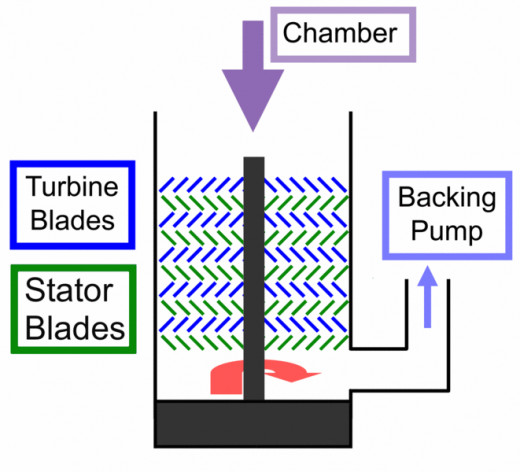

Here you see a cut-away view of a turbo-molecular pump. It is in fact based upon some of the same types of engineering that a turbo-fan jet engine is. It is a finely engineered, micron-tolerance type of device. Not QUITE like a clunking mechanical piston-and-oil or blower-style of mechanical pump. Such a pump, historically would not even operate at a full atmospheres pressure -The Air is too thick for it. There ARE models now that will operate at 760Torr. A turbo-molecular pump, can easily see you to 10E-5 or 10E-6 Torr pressures. And here also you see a turbo-pump attached to a chamber, at work.

If you look closely at the mounted turbo-pump, you see a lot of 'stuff'. There is electro-pneumatic control for valves or switches, electric power, electronic monitoring and computer control elements all often attached. Often, if equipment is mounted within a dangerous location, such as in a beam acceleration tunnel, when the beam is in operation there are secondary radiation exposures. So obviously you will need remote control of this equipment. You aren't always going to walk up to this stuff and throw a lever. Unless you want an x-ray induced tan.

Next here is a diagram showing the functional principle of the turbo-pump. Notice it has a "backing pump". Most turbo-pumps do not operate at one atmosphere. They are brought online after a roughing pump as gotten rid of 90 percent or more of the air and gunk. THEN you kick on the turbo pumps.

Ultra-High Vacuum coming up

Now the third stage of creating an Ultra-High Vacuum is often achieved with the help of a non-mechanical gas-capture style of pump. The ion-pump. The ion-pump is the old tried and true, standard for pulling a few more particles out of a vacuum. Again, it may take a while to achieve the highest level of stable vacuum. You turn the ion pumps on, and they are silent. They often are designed with metal plates inside the pump providing surface-area to capture ions. A high electrical potential across plates accelerates the ions so they are trapped into or onto the interior surfaces of the pump chambers. Thus, a vacuum chamber stands a decent chance of actually achieving 10E-7, 10E-8 Torr, or more...

Now, usually an ion pump basically is a cube or squarish device. -it doesn't have to be. But often they are filled with alternating-polarity rectilinear plates (this is a simplification). and all they need are a connection to a high-voltage source to operate. Then the electric potential slams particles into the plates, trapping them out of the vacuum chambers operating space. In Brookhaven National Labs LINAC (Linear Accelerator) they had ion pumps the size of a full kitchen stove with oven. They weighed around 500lbs, and had huge titanium plates inside them.

There is a good deal of science that goes into just the maintenance and operation / service issues of all the particle accelerators devices. For instance...

In ion pumps, it is possible for there to be a "runaway thermal accident" within the ion pump itself. Picture this. You have a device, the internal environment of which is a highly rarefied gas. You are running a very high electric potential between the plates of such a device. usually it operates at a low current, because there is very little "current" running, due to the rarified gas... But- Suppose you get a higher than usual concentration of "gas", and a decent current starts to conduct across it, focused in one spot...? Since the increased particle density will allow it... current draw increases, and...

Things heat up.

The heat... causes the local release of more particles, molecules or ions from the metals, or any debris buildup upon the plates...

More particles released equals potential for more current to be conducted..

So things get HOTTER...

Now you have a "thermal runaway" situation within an ion pump, where eventually the thing should shut itself down, but not until it has actually started throwing a few ions BACK into the chamber it was supposed to be cleaning. I have witnessed directly with my eyes such a thing, yes, and possibly received a few rads at the same time... but... it was in an experimental situation, where we temporarily blanked off some pumps with plexiglass... ran the pumps and made our measurements and observations. The net conclusion?

We had actually created a quick and dirty magnetron there...

The "hot cell" actually released microwaves... and it all came together to overheat the particular sub-unit of the ion pump, causing self-destruction and shutdown... The "hot spot" literally did glow with a hot plasma. It would be so hot, the plates would melt and warp, eventually it often would lead to a short-out, when the warping plates touched. And shutdown.

That's Physics for you. Always Something...

A few other details of Vac-Tech

In the earlier days, organic components within vacuum systems were commonly accepted. Things like even a rubber O-ring do out-gas though. Even worse, some of the "old school" technicians or engineers used to use all kinds of "goop" to seal up vacuum systems. And more recently, it is just not accepted practice- in general.

The standard is more of an all-metal construction, with crushable diamond metal O-rings. Take a look at the metal flange to the right. You see grooves on the flat circular surface made to accept the mentioned metal O-rings. The flanges and sealing surfaces of vacuum components are torqued-down in an engineered sequence and to torque-tolerances. And, if done correctly. You do get a very nice vacuum seal. The only bad thing of a metal O-ring is, if you think you are going to unscrew it, and then re-torque it... usually it doesn't work. I have witnessed Techs who actually have re-used a metal O-ring before... but once they are crushed, it is usually un-re-usable.

No Organics are desired in Vacuum plumbing or chambers. No volatiles please.

Next, to the right, you see an "ion-gauge". This is to measure pressure with. The fine-wire elements are inside the chamber being measured. It literally is a finely calibrated piece of equipment and measures the number of particles in the space. Usually this is wired to a piece of equipment like in the next picture.

a vacuum gauge controller.

This device will display the vacuum as sensed by the ion-gauge above. That's where the engineers and physicists stand there, watching as the numbers in Torr-units drop, waiting to start accelerating particles. And in a rather large accelerator ring it is possible to have variances from one side of the ring to the other, in pressure or particle density... however you wish to describe it. i.e. You may have a "local high pressure area". Perhaps due to a leak, and you may simply turn on additional pumps in the area to control it and pump it down further.

Next, below the gauge controller, you see another box with wires. It's just a high voltage supply to power an ion pump. Usually attached in close proximity to the ion-pump. Just another box in a jumble of "boxes" that do "stuff" to make a particle accelerator work.

the nomenclature 10E-3 or 10E-12 used above

In mathematics for physics or engineering there is something known as "Exponential Notation". Said plainly in English, the above numbers are "Ten to the minus 3 power" or "Ten to the minus 12th power". Ten to the minus3 power is .01 or "one one-hundredth of a Torr". And "10 to the minus 12", is 0.00000000001 Torr. Ten to the minus12 is a very very low vacuum! In intergalactic space, it is calculated there are 4 atomic particles per cubic meter of space. The best vacuum pulled in a laboratory setting is roughly 350 molecules per cubic centimeter, by contrast. At the "edge of space" very high in Earths atmosphere, the vacuum is roughly 10E-4 Torr, or 3.2trillion particles per cubic centimeter. Yet, we consider 10E-4 to be "space" and is a vacuum.

As you see, "vacuum" is highly relative and is a functional definition only. 10E-4 is a "high vacuum". So is 10E-6, though it still has many particles per cc of space.