Yarn Spinning Machines.( Video of Yarn Spinning Mill in PUNJAB.)

You see Blow Room,Draw Frame,Fly Frame & Ring Frame Working in this video.

Spinning Machine at Subadra Mill,Bangalore.

Yarn Spinning Machine.Running Video.Down.

How Cotton Yarn is made.( Video by Ian Collie.)

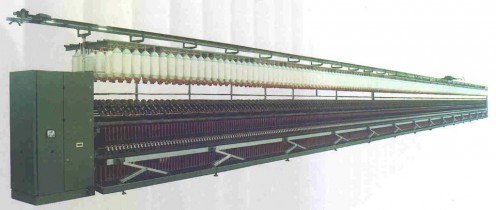

We have come from Blow Room to Spinning the final in spinning a yarn from cotton till now.The machine you see is just a model of a machine made in my own city but of a different machinery manufacturer.This machine is fed from the Fly Frame Machine Bobbins which may weigh up to 1.5 kg and a thousand such bobbins are fed to the machine on a creel supported from the machine.

The bobbin ends are manually drawn and fed to thousand spindles 500 on each side of the machine.The bobbin ends enter the back pair of fluted steel rollers which run through out the machine on either sides.The length of the machine is so long that if a picture is taken from one end the other end will be out of focus as you see in the picture.The length being over eighty feet or more depending on the specifications of the spinning mill.The specifications vary depending on the count.The fine count of say 80's will have a shorter length than a machine spinning 20's count.The Fly Frame bobbin after entering the back pair of rollers the bottom being steel fluted and the top steel shell covered with rubber termed as cot.This bobbin end enters the second set of rollers the bottom roller being steel fluted or knurled and the top from the second now taking the end and drawing it in to finer strand termed as drafting,here it is known as break draft to unwind the twist given at the Fly frame and taken for further drafting up to the front set of rollers to achieve the required count.Once it comes out of the front set of rollers it is given the required twist by the spindles through a ring and a small open ring(very minute)called as ring traveler revolving at a speed of nearly a surface speed of over 1,88,495 inches per minute,with a spindle speed of 20,000 r p m,the diameter of the ring being 1.5 inches.This is the difference that makes the yarn take a twist and get itself wound on to a bobbin called as ring tube.This tube for a ring diameter of 1.5 inches will be 7 inches in height with a taper from the bottom.From the bottom to the top the yarn is wound in what is termed as a cop build by a device that works with the machine.

The yarn that gets wound on to the Ring Tubes will have to be replaced once they are fully wound.The length of yarn on a cop which is a Ring Tube may be as long as 4,000 yards in case of 80's count.The tube is replaced automatically or manually as per the design of the machine,the recent trend being automatically to be replaced and automatically conveyed to the next machine by a system of holders and chains so as to avoid the labour that would other wise required which is a labour intensive proposition as also the skill that is needed.Delay in doing this mannuallu will result in considerable loss of production and if the worker is not skilled will result in wasteage of yarn that would other wise bring money.

The Spinning of Yarn is now over after it got diverted from carding to spinning.However there is a process that is needed if the yarn is to be made smoother and better that is called as Combed Yarn.How is this combing achived is described in Yarn Spinning - Combing.