71

71- 129

Being an Expat in Saudi Arabia

Everything you need to know about living and working as an expat in Saudi Arabia. A full survival guide for expatriates in KSA.

- 1

Decibel Levels and Chart: How Loud Is Loud?

What are decibel levels, and why are they so important? How can you measure them, and when are they too "loud"? Find out in this article with a chart included.

- 26

Work Study; Method Study and Activity Timing (Time and Motion Studies)

Work study; activity timing and method study are an important part of any lean manufacturing implementation if you wish to design manufacturing cells or balance and improve existing flow lines and cells. Time and motion has evolved for Lean!

- 2

What is Takt Time? Defining and Using

What is Tact Time and how do we use it? What is Pitch Time and how is it related to our Tack Time? Tact time creates the basis on which we can create flow and design work cells.

- 8

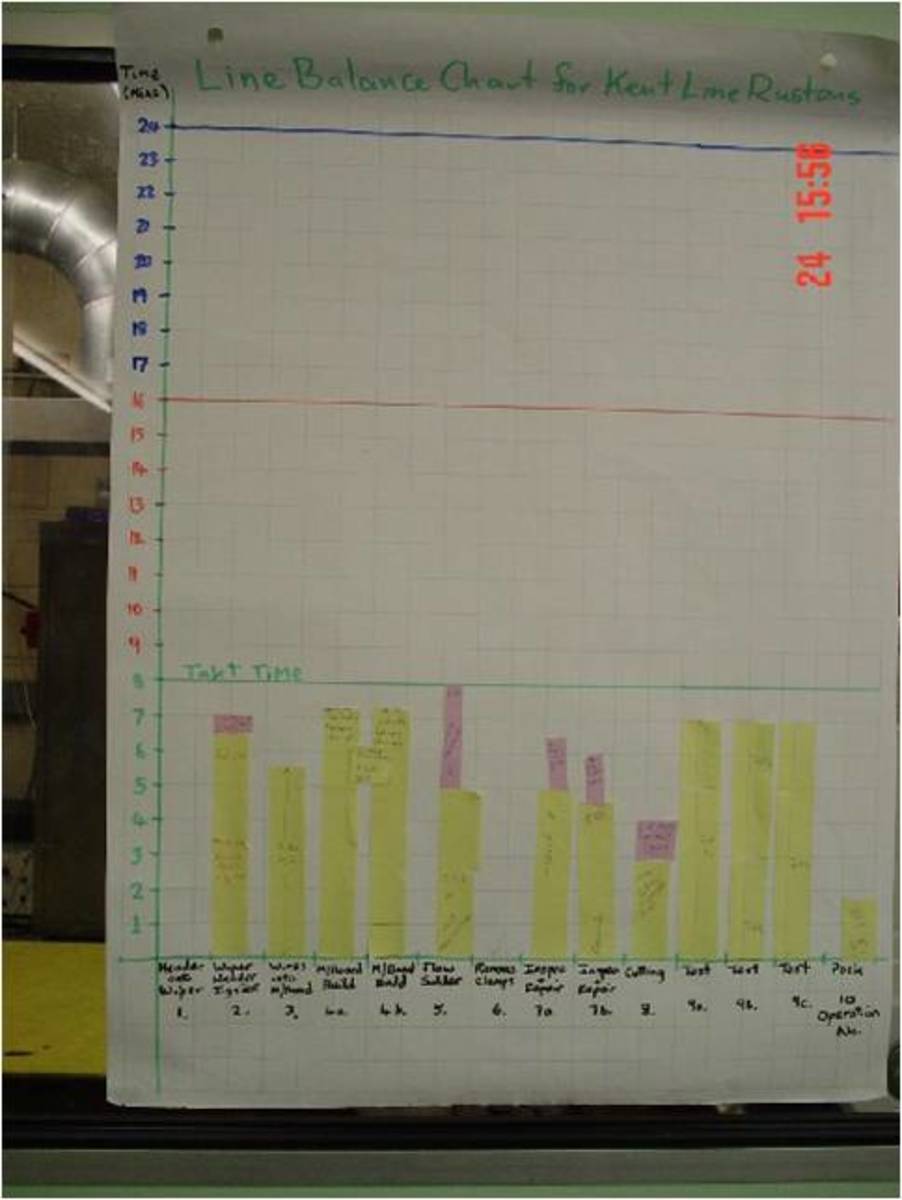

Yamazumi Charts and Boards

What is a Yamazumi chart or Yamazumi board and how do you use it for cell design and improvement? This simple but powerful tool is a highly visual method to drive continuous improvement of your process

- 6

Poka Yoke Mistake Proofing

Poka yoke literally means "mistake proofing." it is about preventing the creation of defects. Poka yoke devices are usually simple and inexpensive, or they can be modifications to the product itself.

- 0

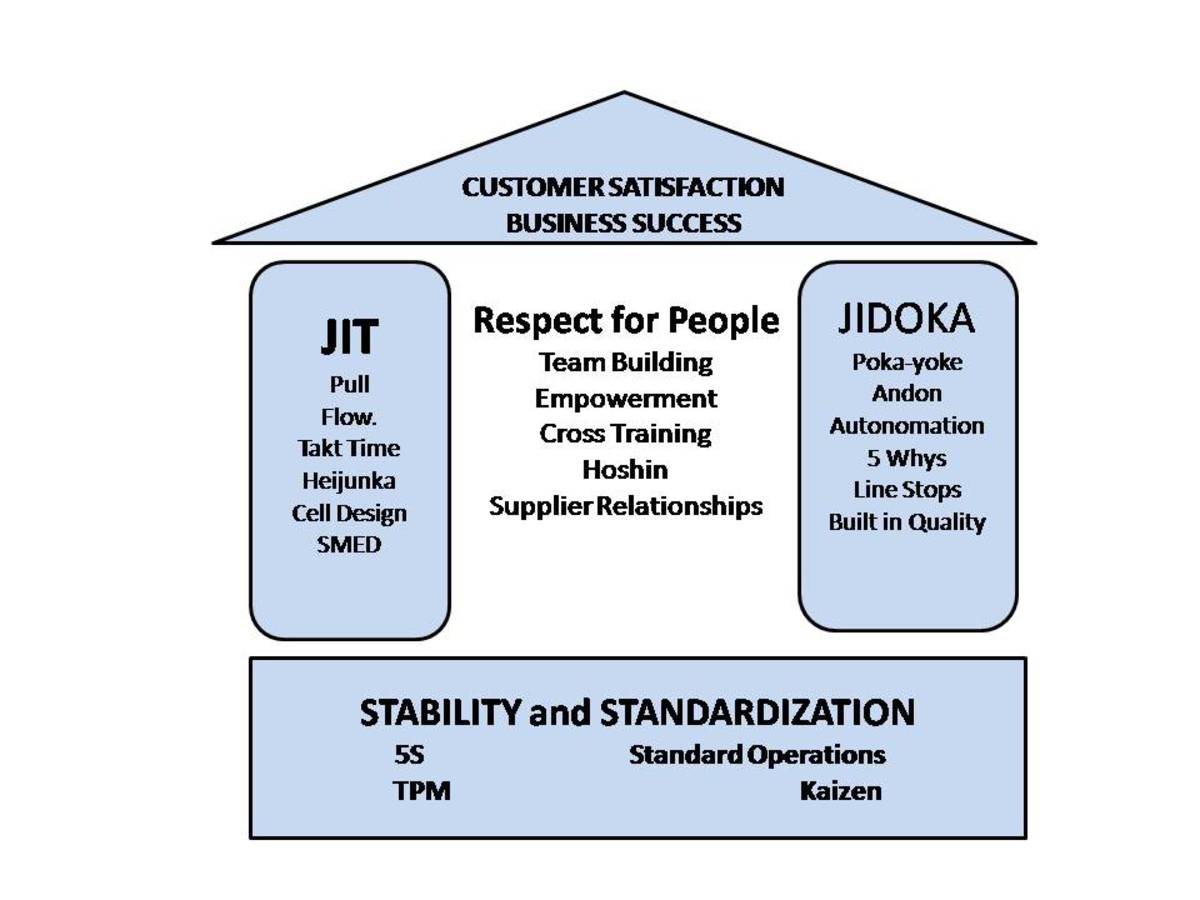

Lean Manufacturing Tools

There are many lean manufacturing tools, this hub summarizes and provides links to some of the more important lean tools.

- 3

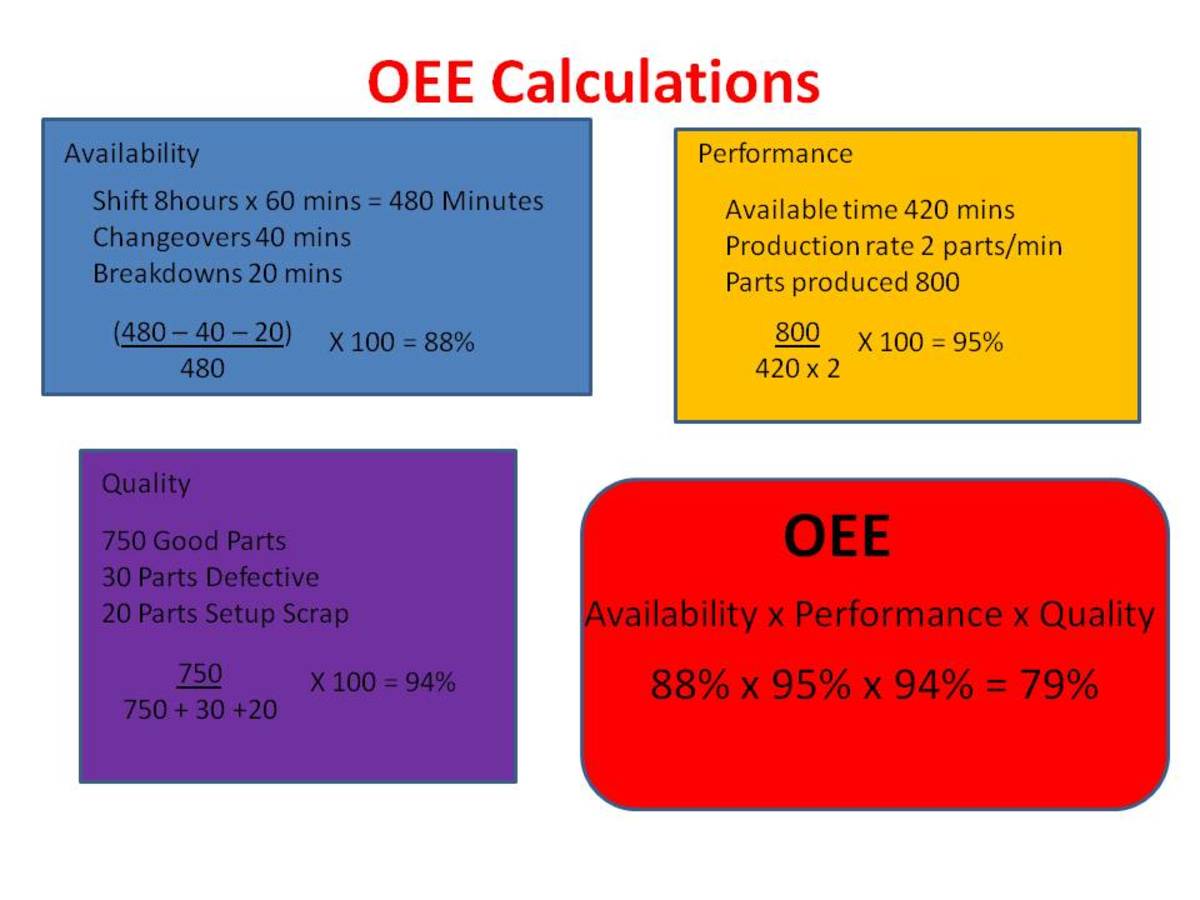

How to Calculate Your Overall Equipment Effectiveness (OEE)

How do you make your OEE Calculation? A step-by-step guide to calculating your Overall Equipment Effectiveness for any TPM (Total Productive Maintenance) implementation.

- 2

5S Games and Training Simulations

Learn what 5S games or 5S training simulations are available and how they can help you train your staff in implementing a 5S program for Lean Manufacturing.

- 40

The 6 Mandatory Procedures Under ISO 9001:2008

What are the mandatory ISO 9001:2008 procedures, and how should they be written and structured for your Quality Management System?

- 4

ISO 9004 Continuous Quality Improvement; Structure for Continual Improvement

Continuous quality improvement is one of the most important factors to ensure the success of your business. ISO 9004 as one of the ISO 9000 family of Standards builds on the requirements of ISO 9001 to create a structure for continual improvement of your quality management system. ISO 9004...

- 6

ISO 9001:2008 Quality Manual and Quality Policy

This Article will show the requirements and structure for your ISO 9001:2008 Quality Manual and your ISO 9001 Quality Policy. Your Quality Management System is very much given direction through your Quality Manual and your Quality Policy, these defining documents of your ISO 9001 system are very...

- 10

Process Mapping Flowcharts; How to map the Value Stream

How to create Process mapping flowcharts and how they can help you to improve your processes. From value stream mapping to Process flowcharts.

- 2

Continuous Quality Improvement Through PDCA and DMAIC Cycles

How we can drive continuous quality improvement using PDCA and DMAIC? Using the Deming Cycle/Shewhart Cycle and DMAIC can help your business grow and compete.

- 2

"5 Whys" Root Cause Analysis: Solving Causes, Not Symptoms

Learn what Five Whys analysis is, how it can benefit your business, and what other people say about it.

- 0

Histograms (Bar Charts) as Quality Improvement Tools

What is a histogram or bar chart, how do we make them, and how can we use them with other quality improvement tools to drive continuous process improvement?

- 2

The Pareto Tool and the 80:20 Rule: Continuous Process Improvement

How to use the Pareto Chart and the 80:20 rule for continuous process improvement. Learn to focus your resources on the vital few.

- 7

Brainstorming and Mindmapping::Continuous Quality Improvement

How to do brainstorming and mindmapping. Use simple creative thinking techniques to brainstorm out solutions to problems and create plans for continuous quality improvement.

- 0

Tally Chart:: Continuous Process Improvement

How do you create and use a tally chart or check sheet? How can you use it for data gathering and then analyze that data? Use a Tally Chart for simple data gathering and analysis.

- 6

Ishikawa Fishbone Diagram; Cause and Effect; Continuous Process Improvement

How do you make and use a Fishbone Diagram, or Ishikawa Diagram to look at cause and effect? This is one of the simple quality tools that can help a company achieve Continuous process Improvement.

- 10

7 Tools for Continuous Quality Improvement

What are the 7 quality tools and how do they help drive Continuous Quality Improvement?

- 110

Makkah Clock Royal Tower:Biggest clock tower in the world in Mecca:Pictures:Photos

The Makkah Clock Royal Tower is the third tallest building in the world as well as the biggest clock tower in the world. Overlooking the Haram and Kaaba in Makkah (Mecca) as part of the Abrj Al-Bait development. The Makkah Clock tower will be visible for 17km and is 6 times bigger than Big Ben....

- 31

Saudi Arabia Road Travel by Car From Riyadh to: Dammam: Jeddah: Al-Khobar

What is it really like to drive from Jeddah to Riyadh or even Al-Khobar? Read my experiences and unbelievable stories of Saudi Arabia Road Travel; Accidents, guns, police and even monkeys!

- 452

Saudi Arabia Work Visa; Business Visas to Visit KSA

How to get your Saudi Arabia Work Visa or other visa to either visit or do business in the Kingdom of Saudi Arabia (KSA). Being a victim of Extortion, an Illegal immigrant and escaping Saudi Arabia!

- 394

Dating in Saudi Arabia KSA; How to Date Muslim Saudi Girls

Want to go dating in Saudi Arabia? Are you feeling lonely in KSA? Would you like to know how to go about meeting and dating Muslim Saudi girls and women of other nationalities in Saudi Arabia (KSA). There are many girls from Filipinos and Indonesians to Moroccans and Lebanese women. Don't lose your...

- 102

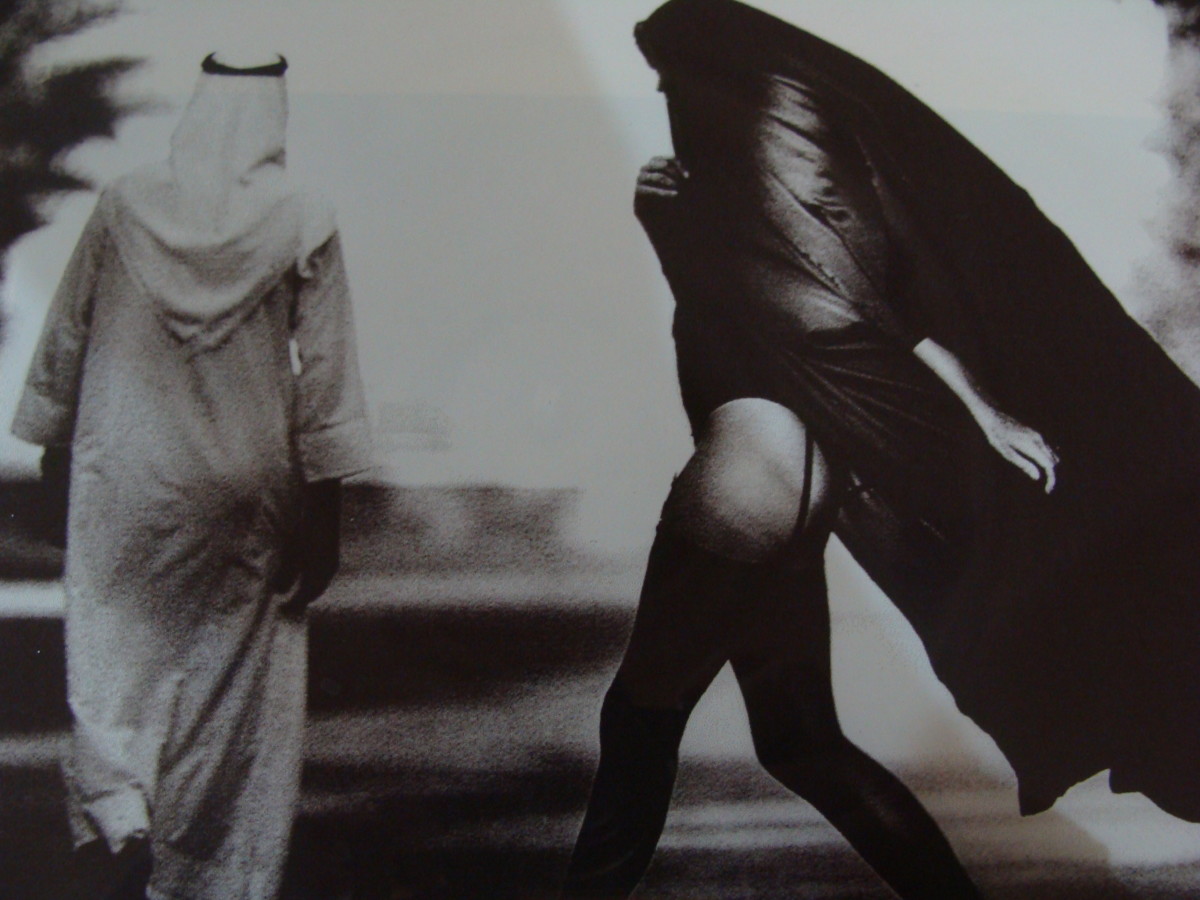

Saudi Arabia Women; Can an Arab Muslim Arabian Woman Work in KSA?

In Saudi Arabia Women are not entitled to the same freedoms that we in the west take for granted, this hub will look at everything from how to dress, education, can an Arabian woman work, driving, segregation, abuse, marriage, divorce, Adultery, punishment even death by stoning for Saudi Arabian...

- 176

Western Compounds and Expat Housing in Saudi Arabia

Need to find a western compound in Saudi Arabia or even an apartment off-compound in Riyadh or Jeddah? This article contains all the information you need about finding accommodation and living in KSA.

- 655

Expat Living and Working in Saudi Arabia: Rules, Regulations, Laws

As an expat living and working in Saudi Arabia, I want to give you the real truth about working in the Kingdom. What are the rules and laws that you must follow if you are going to work here?

- 276

Working as an expat for a Company in Saudi Arabia

As a western Expat living and working in Saudi Arabia I want to tell you what it is really like to be working as an expat for a company in Saudi Arabia. The Saudi's work ethic, why they employ expats, how expatriates are treated, women at work, the use of Insha'Allah, being paid and other subjects.

- 249

Expat Workers Treatment By Saudis; How Expats are treated in Saudi Arabia

just how are expat workers treated by Saudis?As a Western Expat living and working in the Kingdom of Saudi Arabia (KSA) I would like to give you some information regarding the treatment of expats in Saudi Arabia. Not just how they treat westerners but Indians, Indonesians, Filipinos and other...

- 2

How to Create a Value Stream Mapping Symbols

VSM (value stream mapping) is a tool to help you define a current state map of your product and information flows. Through identifying and eliminating waste, you can create a future state map.

- 0

Value Stream Mapping : VSM

Value Stream mapping (VSM) is a technique by which you review the flow of materials and information through the whole supply chain. Mapping from raw materials through to delivery to customer. Value Stream Mapping lets you identify all of the waste within your business and create a future state map...

- 0

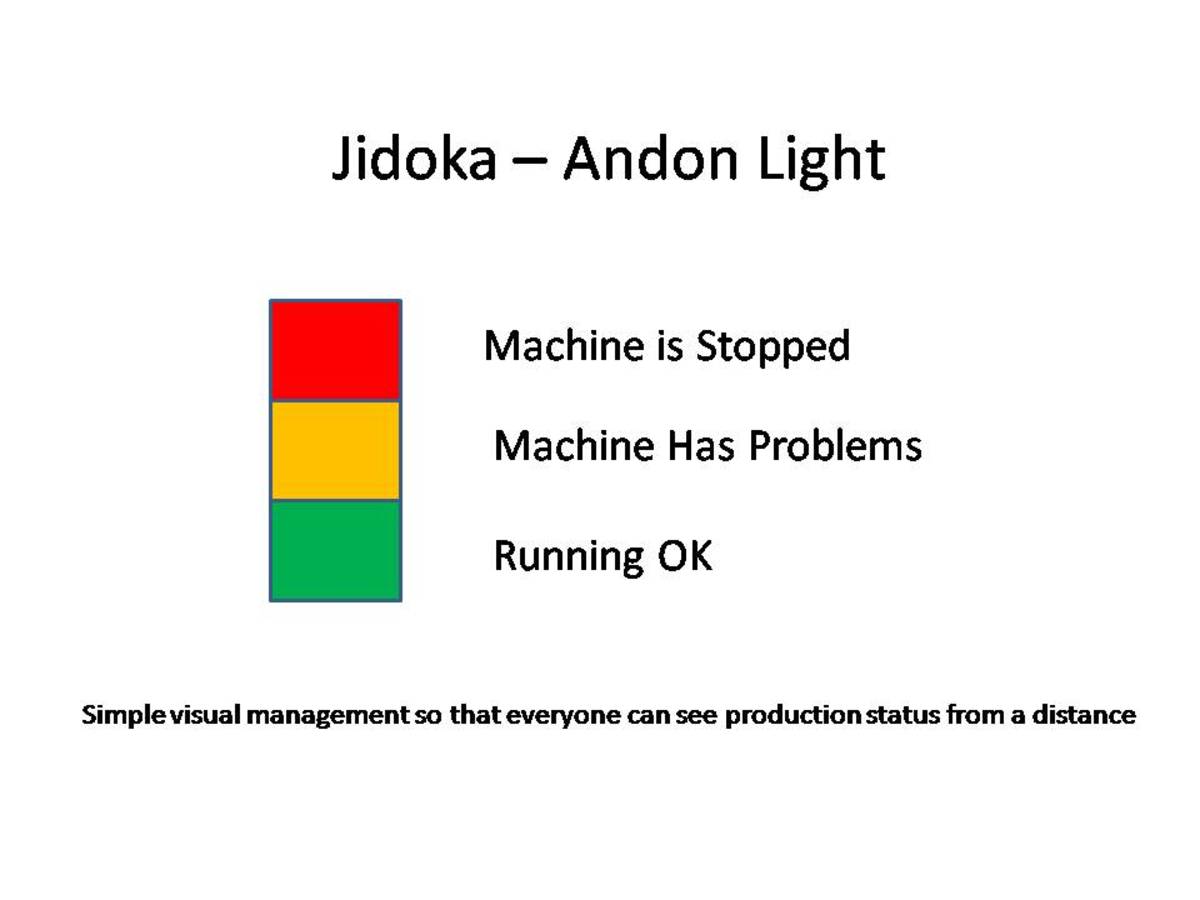

What Are Jidoka and Autonomation?

Autonomation, or Jidoka, is one of the less well-known principles behind the Toyota Production System. Jidoka is about having machines with “human” intelligence so that they stop when something is wrong.

- 0

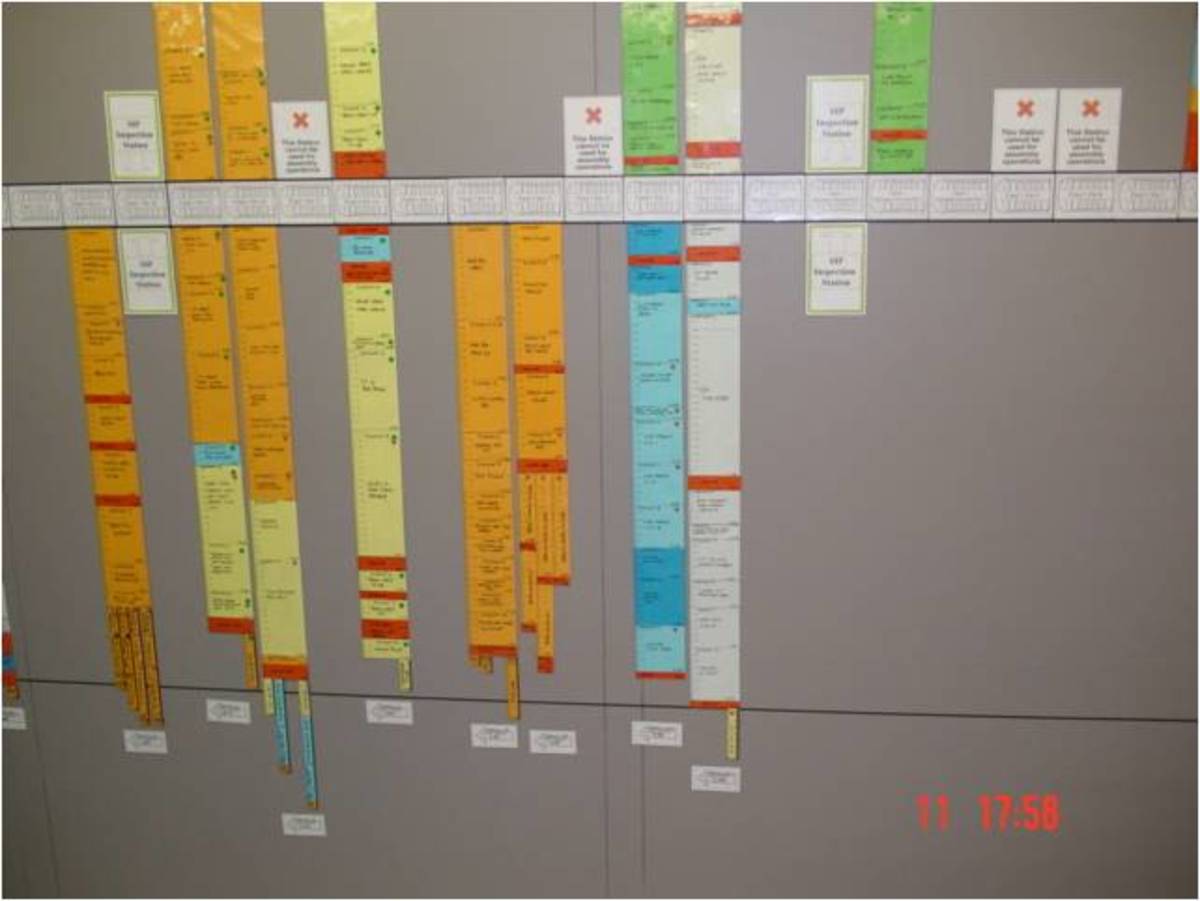

Leveling Production Using a Heijunka Board or Box

Tools such as the Heijunka board or Heijunka box coupled with Kanban can help your business to reduce costs and increase profits as well as giving a far better service to your customers.

- 10

SMED: Shigeo Shingo's Single-Minute Exchange of Die

What is Shigeo Shingo’s Single Minute Exchange of Die or SMED and how can you use it to reduce setup or changeover times for your process. Here are SMED examples and full details of how to implement this powerful lean tool.

- 0

Reduce Mura to Level out Production

Most lean manufacturing practitioners think of Muda when you talk about waste, but there are two other types of waste: Mura and Muri. Mura is the waste of unevenness or inconsistency. Therefore, we need to reduce Mura to level our production.

- 0

What Is Muri (Overburden) in Lean Manufacturing?

Muri, the Japanese term for "overburden," refers to the strain that we put on our workers by failing to smooth production and standardise our processes.

- 0

7 Wastes: The Seven Muda

The Toyota Production System (TPS) uses Muda, Mura and Muri to signify waste within their system. What are the Seven Muda or seven wastes, and how do we eliminate them from our processes?

- 4

Using Kanban to Calculate Your JIT Bin Quantities

If you wish to use a Kanban formula to pull production through your Just in Time (JIT) process as part of your lean manufacturing initiative, then you need to understand how to calculate your Kanban quantities.

- 0

Kanban Cards; Kanban System Types; Bins, Card, E-Ban, Faxban, CONWIP

What are the different types of Kanban systems; Kanban cards, Faxbans, E-bans, CONWIP, 2 bin systems, 3 bin systems, multiple bin systems? How does Kanban work?

- 0

Kanban - Manufacturing Pull system - Bin Systems and CONWIP

Kanban is a sign, flag, or signal within the manufacturing production process to trigger the production and supply of product as part of Just in Time in Lean manufacturing. Kanban or Kamban is the main method by which production pull is achieved using Kanban systems such as the 2, 3 or Multi bin...

- 9

How to Become a Lean manufacturing Consultant

Are you considering employment as a lean consultant! Why? Are you after fame, fortune or just want to get the girl? Before you run out to discover how to become a lean manufacturing consultant and quit the day job you need to look carefully at your motivations. Working as a Lean manufacturing...

- 3

5C Workplace Organization for Lean Manufacturing

What is 5C workplace organisation, and how is it implemented? This article will tell you how to reorganise your environment into something safer and more efficient.

- 4

The Lean Office: The 5S Office

How you can implement 5S in an office environment to gain efficiency and prevent defects.

- 5

5S Training

How to conduct 5S training and understand if you have achieved your goals. Either in-house training or hiring a lean trainer for your 5S training program

- 5

Using the 5 S's: Seiri, Seiton, Seiso, Seiketsu, and Shitsuke

What are Seiri, Seiton, Seiso, Seiketsu and Shitsuke? What is 5S and what does it mean in English? Definitions and details of the different stages and their implementation within Lean Manufacturing.

- 1

Benefits of 5S: Is Lean 5S Just Housekeeping?

Learn why 5S Lean Manufacturing is so much more than just housekeeping. Here are all of the benefits of implementing a 5S program.

- 10

Just-in-Time (JIT) Manufacturing

What is Just in Time (JIT) Manufacturing, what are its origins, how does it work, and why should you implement it?

- 29

TIMWOOD: The Seven Wastes of Lean Manufacturing

TIMWOOD is a mnemonic to remember the seven wastes in lean manufacturing: transport, inventory, motion, waiting, overproduction, over-processing, and defects. Learn more about each component below!

- 10

Benefits and Advantages of Lean Manufacturing

What are the benefits of lean manufacturing, and what are the advantages of lean production? Lean manufacturing can benefit your business in many ways, from reducing your scrap and space required to reducing lead times to a fraction of your current lead times.

- 9

History of Lean Manufacturing

Understanding the history of lean manufacturing and how and why it developed will help you in implementing lean effectively to improve your organization.

- 19

What Are the Principles and Concepts of Lean Manufacturing?

What is lean manufacturing, and just what is a good lean manufacturing definition? This article will try to give you a concise lean manufacturing definition and show how it compares to agile manufacturing and Six Sigma.