How to Turn Two by Fours - an Introduction

This article is the first in a series of articles showing how to turn many useful and attractive items out of the lowly construction two by four.

My Start in Woodturning

I turned my first bowl in middle school before I even went to high school. I still have it. Later I got to turn the legs for four toddler size chairs on my older brother's lathe. That was pretty much it until after I got married and managed to save up enough money for my own lathe. The only problem is I had the lathe but no materials for turning anything. All I had was two by four cutoffs left over from building some outbuildings. While not the ideal wood for the job, I persisted in creating things on my lathe and this article is a distilling down of the knowledge gained.

What You Need to Know Before You Start

Most construction-grade two by fours in Canada and the United States are made from either Yellow Pine, Douglas Fir or Spruce. Spruce is divided up into three native species: Red Spruce, White Spruce, and Black Spruce. In addition, Norway Spruce has been introduced and harvested within the lumber industry. I live in Eastern Canada and virtually all construction-grade two by fours I have access to are made from Spruce. I have turned at least two of the four different species and find there is no qualitative difference between them when it comes to turning them on a wood lathe. They are all prone to chipping and tearing out. I cannot speak directly to Douglas Fir or Yellow Pine but I have heard they have similar problems. Hopefully, someday I can get my hands on some samples and assess them directly. Spruce is my focus here and I want to address the most important question: Can you turn a piece of Spruce on your lathe in spite of its drawbacks and create something useful and/or beautiful. My answer is an emphatic yes. Check out the slideshow of my past work to get an idea of what I mean.

Products Turned From Spruce Two By Fours

Keys To Success

You're only going to get good results from any material if you work within its strengths and weaknesses. I think Spruce two by fours are a great material to learn woodturning with because it's not very forgiving. If your tools are dull, your technique is bad and your designs ask too much, you're going to be making firewood.

Spruce tears out and chips easily. Don't fight it. You'll lose.

Keep Your Tools Sharp

You don't have to make sure the cutting angles on your tools are perfect so you don't have to be a master tool sharpener before you begin. You do need to be able to put a keen edge on them though. The better you are at sharpening the better work you'll be able to do.

I would suggest starting out with a cheap but adequate set of lathe chisels. They can bear the brunt of your learning. Take the time to learn from an expert. There are plenty of them online on Youtube. Watching these videos has helped me improve immensely.

Turning Spruce is hard on your cutting edges. I don't know why entirely. I've read some sources that blame silica in the wood or chemical reactions between the resins and the steel in the tools. I just know that when I turn Spruce I spend additional time sharpening tools compared to when I work with some of the more common woods I have access to. To help I always cut the corners off my turning blanks before I even mount them on the lathe.

Work On Your Technique

All the instruction I got at the beginning was watching a shop teacher turn a small bowl with a round nose scraper. I started out using all my tools as scrapers. That kind of technique will only take you so far. I continue trying to improve my technique but would not consider myself even close to being an expert. I can recommend several Youtube turners that have been very helpful to me. Any of these people can make you better: Brian Havens, Mike Peace, Ashley Harwood and the guy on the channel wortheffort. There are probably quite a few more that I haven't mentioned but I don't have the time to listen to everybody.

If it's any comfort, you will improve with practice.

Design

Trying to cut fine details into Spruce is a mistake. I find that no matter how sharp my tools are and how carefully I approach my cuts there are details that chip or tear-out. I don't mind a chip here and there. That often adds character to one of my pieces. When most of a fine bead chips away, it's time to reconsider what you are trying to do.

My recommendation is to simplify your designs and try to avoid details that are likely to fail. Simple elegant designs can be just as effective as finely crafted detail.

If you take the time to take these three points into consideration, you are well on your way to making beautiful things with two by fours.

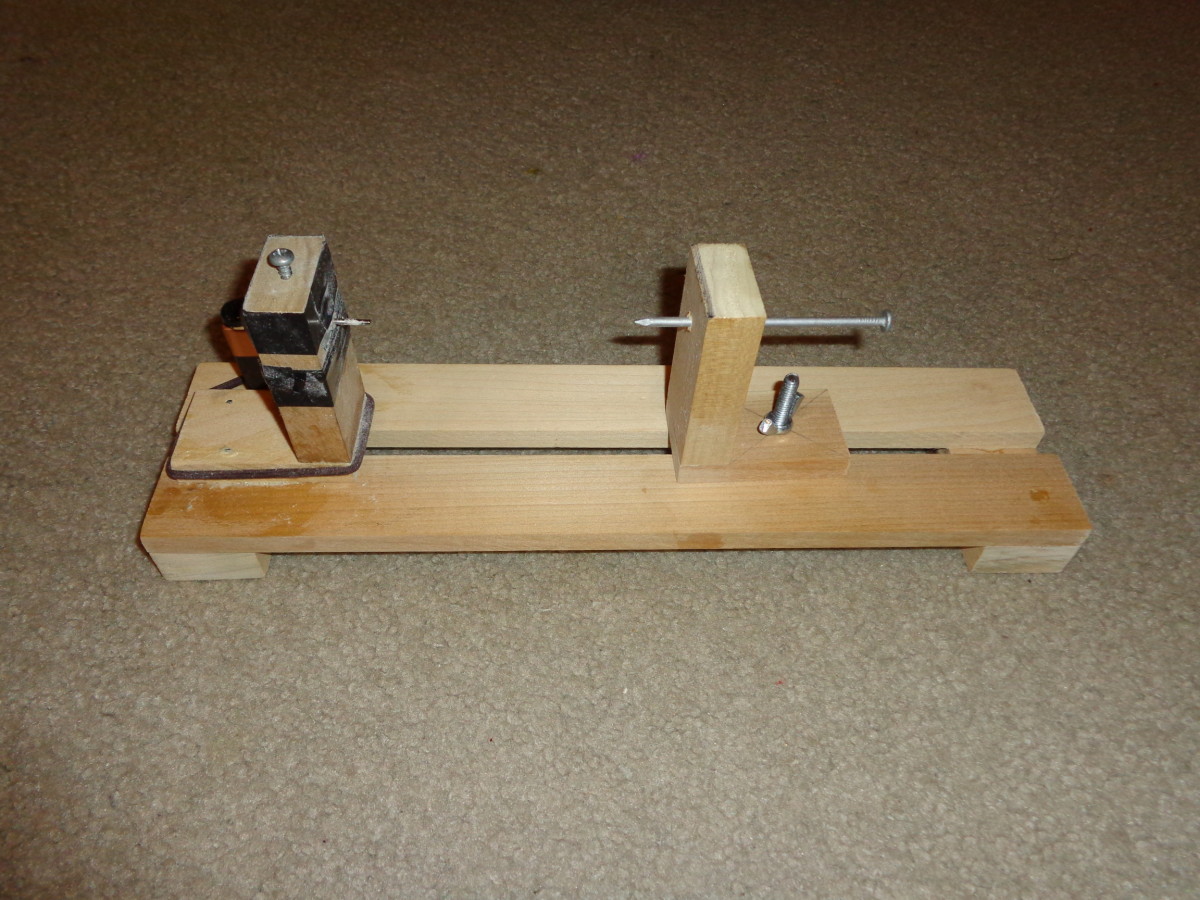

Lathe Chisels

Bench Grinder

Big Upside For Two By Fours

Two by four material is one of the most economical sources of wood out there. Companies and people will often give away cutoffs for the asking. Even if you have to buy full two by fours, they are about the most inexpensive woods going. The advantages don't stop there though.

I don't own a jointer or a planer yet laminating two by fours into turning blocks is no problem. They are cut to dimensions and they are planed. As long as they are clean there is no preparation needed, just glue and clamp them together.

I glue them into simple blocks for turning bowls and also glue two face to face to make large spindles. That is only the beginning of what you can actually do. If two by fours are the only material you can get, there is no reason to give up on turning.

Hidden Cost

Turning two by fours instead of prime material does have two hidden costs that you should be aware of before you begin. Because you have to sharpen your tools more often, they will wear out and need to be replaced sooner. The other hidden cost is sandpaper. This material does not cut as cleanly as topnotch turning woods and will require more sanding before applying finishes. While these to costs are not huge over time they do become significant.