- HubPages»

- Arts and Design»

- Crafts & Handiwork»

- Textiles

How to Spin Wool into Yarn

Why Spin Wool?

Wool has an important and long standing relationship with humankind; it has been in use for over 12,000 years!

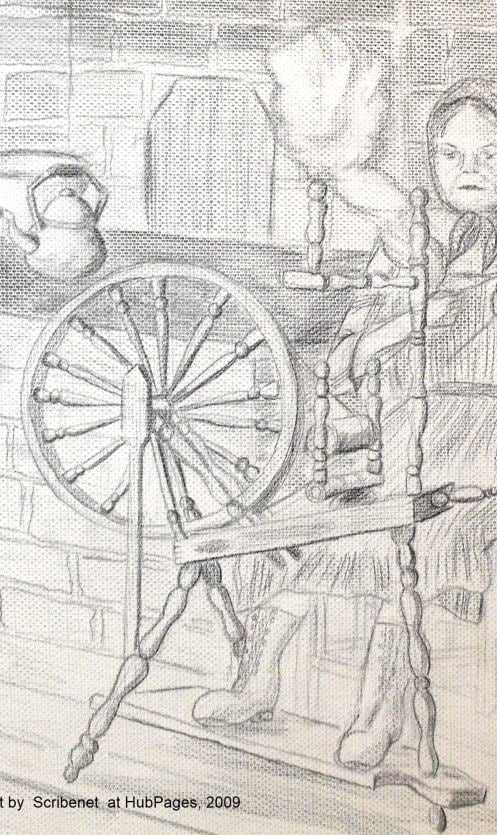

Spinning wool is both simple and complicated. Simple because you don't need much equipment. Complicated because it takes some measure of skill to master the technique. The reward is creating a garment from a pile of fluff!

As an organic fiber there is no equal in the natural world. Humans have used wool and wool products in one form or another for eons.Wool is also one of the easiest fibers to spin, which makes it a logical choice when beginning spinners.

The Importance of Wool

Sheep migrated along with humans to colder areas providing early man with renewable sources of fiber from their fleece besides also being an important food source. Civilization indeed is partly due to the domestication of sheep and the commerce that was a direct result of the wool trade.

Wool has many admirable qualities that make it ideal for garments for hot or cold climates. Surprisingly wool is even great for use in rainy weather.

Wool can hold up to 30% of it's weight in water and still not feel wet against the skin...one reason that Scottish shepherds wore woolens in the cold, damp highlands, Bedouin nomads sheltered under woolen caftans in the hot desert to keep out the heat. Wool fleece was put out in the cold night in the desert in biblical times and water wrung out it in the morning where it had condensed overnight.Wool in the form of felt was and still is used to build Mongolian yurts (portable tent-like homes). That is versatility!

Wool is resilient, strong, warm, cool, water resistant, fire resistant, and very long wearing provided you know how to wash it. Wash it incorrectly and you may get wool felt!

Because of it's versatility and unique characteristics wool is a particularly rewarding fiber to spin into yarn.Best of all, spinning wool requires very little in the way of equipment.

What you will need

Spinning wool is a simple process which can be done with very basic tools.

The most basic equipment needed is a drop spindle and sections of processed wool....(unprocessed wool is unwashed containing debris,lanolin and manure tags...yuk).

How Wool is Spun on a Drop Spindle

- The first step is to tie a "leader" ( a piece of ready made yarn length) around the dowel to of the drop spindle to hold the spun yarn in place...while the remainder of the leader is wrapped over the disc and into the hook attached to the disc. The wool yarn hangs and twists into yarn from this hook as the hanging spindle is twirled in one direction until a length of yarn is spun.

- The second step is to draft some strands of fleece into a length suitable for the thickness of yarn to be spun. The drafted wool is overlapped unto the leader yarn as the spindle is dropped and spun clockwise until the right twist is in the yarn works up the length of drafted wool. The drafting and spinning continues until the yarn is too long to manage and needs to be wrapped around the dowel.

- The wool is pinched to stop the process of spinning or for that matter to stop the wool from unravelling while the yarn is wound around the dowel.

- The spun yarn is wound around the dowel. As one length is wound onto the dowel, another length is drafted from the fluff and set to spinning as the spinner keeps pinching and drafting the wool fibers in a coordinated and hopefully even manner.

- The trick is to get the yarn nice and even. This type of spinning typically produces a wool yarn that has flaws that add to the appeal when it is crafted into the final product.

- Beginners will no doubt get a very uneven yarn so speed is not the objective, rather an effort to get the feel for how much wool to draw out each time as well as how much spin to give the spindle.

The yarn is spun until the dowel is full. Once full the wool has to be un-wound and re-wound into large skeins created by winding around a chair back or from elbow to hand creating a large loop which is then gently and loosely wound.

The finished skein needs to be placed in water (gently) to condition the yarn and then hung to dry with a weight to take out the "kink".

As you can see, this isn't a quick craft and this is one skill that is akin to learning to ride a bicycle effortlessly. Practice makes perfect.

Wool Terms Used for Spinning

Drop Spindle: Drop spindles are simply round tapered dowels with a weighted disc on one end with an attached hook. The weight of the drop spindle determines the thickness of the yarn. Lightweight spindles produce lightweight yarns. Heavy spindles produce bulky yarns.

For beginners a medium weight spindle is considered the best.

Fleece can be bought natural or dyed various colours.

Rovings: Cleaned and washed raw fleece. You might want to buy raw fleece but it must be washed of lanolin, dirt and manure tags! A long process; then the fleece still needs to be combed and finally carded before it is ready for spinning.

Combed wool: After washing the wool is combed to free it of debris like straw and other foreign objects.

Carded Wool: Wool fleece that has been washed and brushed to align and straighten the fibers so they are untangled and easy to draft prior to spinning into yarn.

Drafting Wool: The process of gently pulling out a certain number of fibers from the carded piece of wool. The fewer the strands, the thinner the yarn will be. No matter how thick this final yarn is, it is called one ply. To create two ply another yarn must be created and combined with another one ply yarn.

Woolen Longdraw for Spinning

- Woollen Longdraw-for handspinning

Spinning yarn seems magical. See exactly how wool fiber is twisted creating yarn. This yarn then can be used to create hats, scarves,or even handbags.