- HubPages»

- Arts and Design»

- Crafts & Handiwork»

- Paper Creations

How to Make a Mould and Deckle for Handmade Papermaking

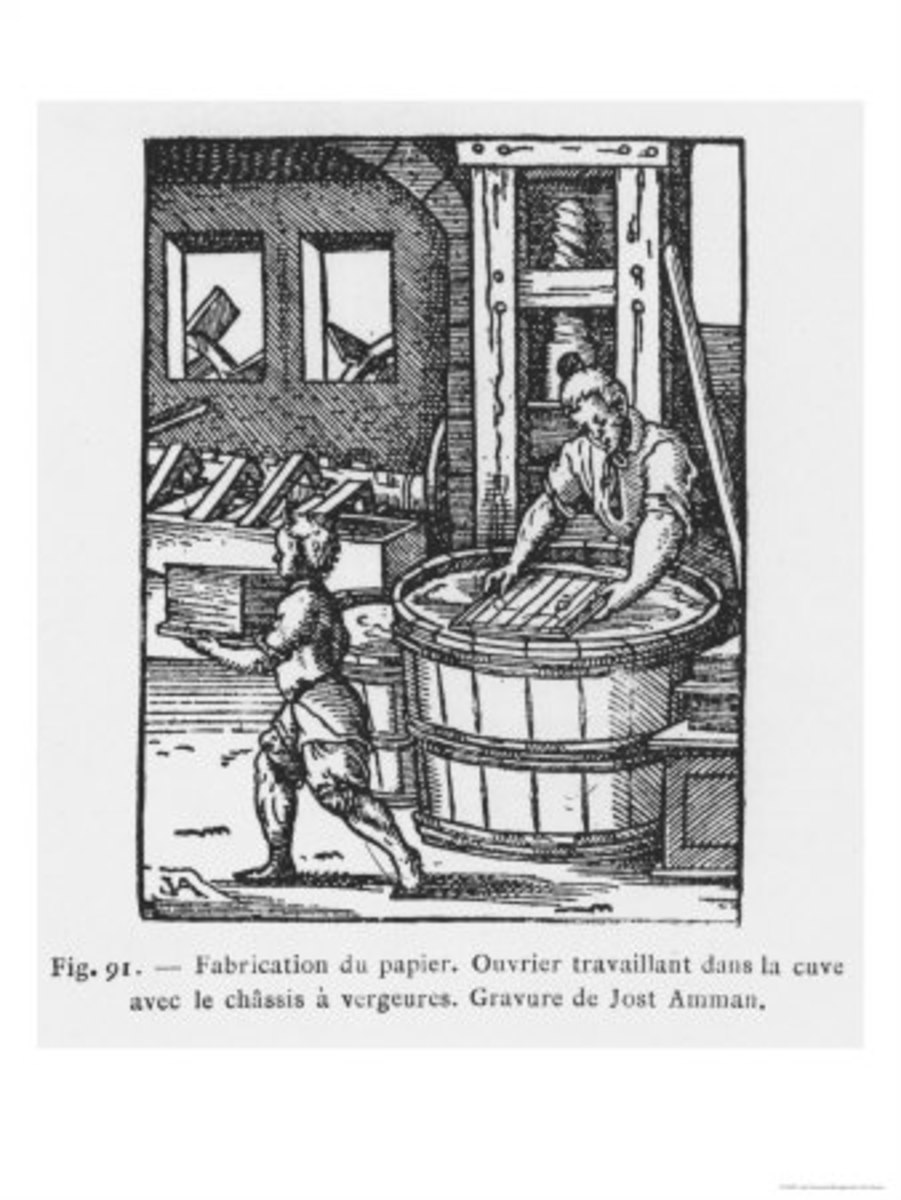

Essential Tools for Papermaking: The Mould and Deckle

If you are interested in making your own paper, a mould and deckle is an essential part of your equipment. Fortunately, this set is easy to make and will last for many years. And by making your own, you will be able to have any size paper you wish!

Take care in the construction of your mould and deckle. Otherwise a sharp edge could produce a very painful injury, and in any case, you will want your mould and deckle to last for years, so a little painstaking work in the beginning will repay itself many, many times over!

A Papermaker Using a Mould and Deckle

Making the Mould and Deckle for Wove Paper

What you will need to make these tools (they can be reused for many years):

- old metal window screen

- hardware cloth

- small pieces of wood about 1" x 2" x 12" (alternatively, you can use two old, identically-sized picture frames about ¾" deep)

- sturdy upholstery staples

- nails (do not succumb to temptation and use corrugated nails--use finishing nails instead!)

- saw

- sandpaper

- wood sealer

- water-resistant or waterproof varnish

Cut the wood and mitre the corners to make a frame about 9" x 12" (or to desired size). Use good-quality nails to hold it together--you will want it to be strong! Now make another frame the same size. You should have two frames, one that will fit on the top of the other. Sand the edges to make sure they are smooth (you don't want splinters!) and seal the wood with a product like Thompson's Water Seal or a penetrating oil, and then give them a coat of a waterproof varnish. Now take one of those frames and set it aside. On the other frame, stretch the hardware cloth over it (use a big enough piece to cover the whole frame in one piece). Staple one edge with sturdy upholstery staples to the wood, and then stretch it as hard as you can to the other edge and tack a staple in at the top corner. Start stretching the hardware cloth down as hard as you can, and continue to stretch and staple until the frame is tightly covered in hardware cloth and stapled securely on all four sides.. Repeat with the window screen on the same frame, so that the hardware cloth is underneath and the window screen is on top. Now you have your mould and deckle, which is what you will use to pull the paper pulp from its suspension.

Making the Mould and Deckle for Laid Paper

Laid paper requires the use of small wooden strips across the surface to make the "laid" pattern. You make your mould and deckle as above, but instead of the hardware cloth and window screen, you can cut down an old bamboo placemat to size, and use your staples to staple the place mat to the frame. (In this case, you may want to make the deckle slightly larger than the mould, but overlap the widths. To put it another way, if you have a mould with an 8½" opening, you might make the deckle ¼" larger. It will still touch the other frame on all four sides.)

Making a Watermark

If you hold good-quality paper up to the light, you will often see a design or logo of the brand. This is called a "watermark," and you can make your own watermarks very easily once you have finished constructing your mould and deckle.

You can use a thin piece of wire, or you can use a waterproof glue. If you want a less permanent watermark (such as for experimenting to get the right look), you can lay down a thin bead of caulk or rubber cement. Whichever material you use, watermarks are made in the same way.

On the underside of the screen, attach your wire (or draw your glue) in the desired shape. When you pull the mould and deckle through the pulp, the pulp will be thinner where the watermark is, and that thinness is what makes the watermark in the paper!

Care of Your New Papermaking Equipment

After using your mould and deckle, you will want to keep it in good condition. Thoroughly rinse off any bits of pulp clinging the the mould and deckle, and wipe off with a damp paper towel. Inspect for sagging screen or sharp edges of screen, hardware cloth, nails or staples poking out and correct if necessary. When varnish starts to wear, reseal with water sealant and revarnish the wood.