Twisted Sisters & Company Fibre Mill Tour

From Alpaca to Yarn

For many crochet and knit enthusiasts, much of the pleasure of our craft is in the yarns we use. There's something special about browsing through a yarn shop, enjoying the colours, feeling the textures, and getting inspired! A beautiful yarn flows smoothly through our fingers, our hooks or needles flashing as we form simple or intricate fabrics, creating items we proudly use, wear, sell or give away as gifts.

Unless we are also spinners and weavers, we don't often get a chance to see how these beautiful yarns are made. In August of 2012, I had the pleasure of being part of a group tour of Twisted Sisters & Company Fibre Mill, located South of Edmonton. There, we were able to see the process, from animal to yarn! It was a pleasure visiting the mill, and we learned so much!

Image of alpaca roving in the Twisted Sisters store. All photos are my own, taken during the tour.

Beginning at the beginning - the Alpaca

Visiting the Alpaca

Fibre on the hoof

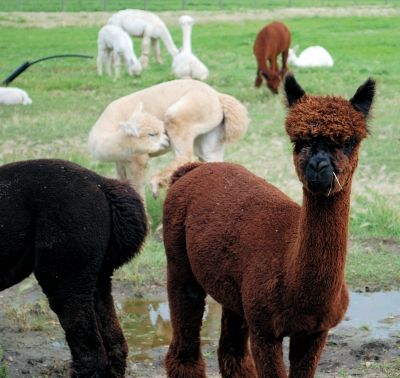

We began our tour by visiting the mill's breeding herd of Alpaca. Alpaca are lovely, social animals that get along with other animals as well. For a while, they seemed as curious about us, as we were of them, coming close to the fence to check us out. Our tour guides told us about their herd, including the care, sheering and breeding of them. Twisted Sisters uses fibre from their own animals to make yarn, as well as processing fibre shipped to them by customers.

This is my good side.

Cleaning Raw Wool - The first step

After visiting the alpaca, we went into the mill to view the processes raw fibres need to go through before becoming luxurious yarn. The first step is to wash it, twice. Raw wool is quite greasy, as well as filled with dirt and debris. Small amounts are gently washed at a time, in separate compartments, to prevent felting. Kevin, our guide, told us about their experiences learning how to properly wash the wool, through a combination of advice from others and trial and error. Water temperature, amount of detergent, and what to use in the second wash was all part of the learning process.

Time to Dry - The next step

Once the raw wool has gone through its washes, it is spread out on racks to dry.

Strands of alpaca wool is typically about six inches long, but modern breeds can have strands eight or ten inches long - some as much as 12 inches! The finest wool is from an animal's first sheering - the coveted baby alpaca. We learned that alpaca show their stress in their wool. Some alpaca (not all) are stressed when they are weaned, and it shows as a weak spot in their wool. This can be tested by taking strands of wool from fleeces such as the washed and dry wool pictured here, and pulling on them. If you hold it near your ear as you do it, you can actually hear the strands tearing.

Weak wool cannot be spun. It would tear apart during processing, and the strands would become too short to spin into yarn. At best, it can be made into felt. Sadly, the mill has received shipments of wool from customers that they could not process because of this.

Cleaning and Separating

Though the wool has been washed, it's not quite clean yet. After drying on the racks, the washed wool needs to be further cleaned. The dried wool is spread out on the belt of a machine that combs through it, taking out any bits of grass, leaves or sticks that might still be trapped in the strands.

Once picked over, the wool is moved to a second machine that further combs through it, separating the clumps of wool apart. By the time it comes out the second machine, the wool is a gossamer sheet of softness, so fine, it can barely be seen until the pile of it builds up.

Baby Alpaca wool, washed and cleaned

Carding

The next step for the fully cleaned wool is carding. The carding machine is fascinating to watch! The raw wool is placed on a belt at one end, where it passes through a series of rollers that card the wool. If quilt batting is required, it runs down to a drum under the machine. Most of the wool is processed into roving, which comes out the other end, dropping into special bins, looking for all the world like soft ice cream going into a cone!

Preparing the Roving

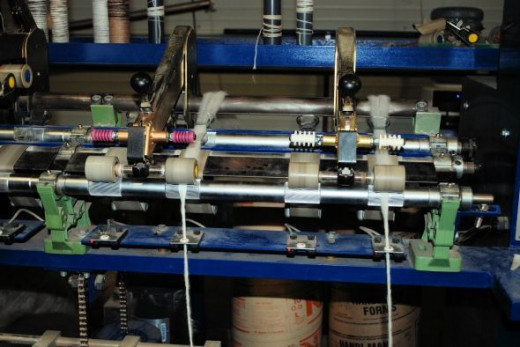

The roving from the carding machine isn't ready yet! Pairs of thin roving from the carding machine is run through another machine, where a series of smooth and toothed rollers combines them.

Through the roving machine

Spindles

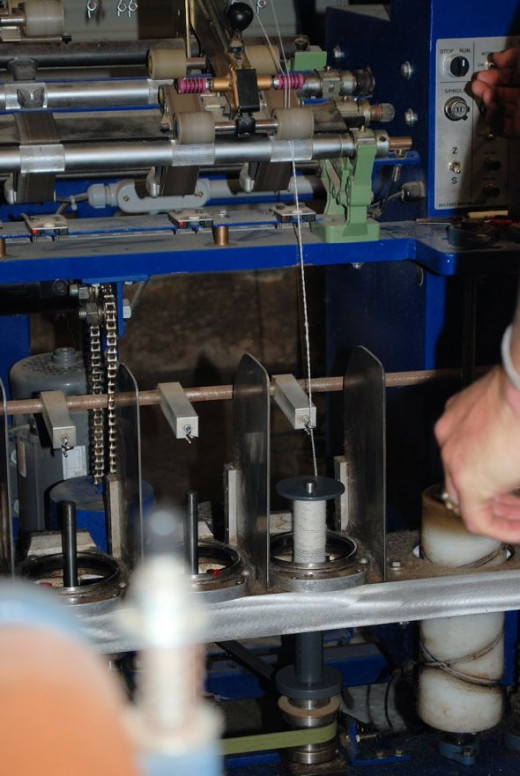

Once the roving is ready, it can either be packaged and sold as is, or it moves on to a spindle machine. Here, the soft ropes of roving are twisted into single ply strands.

Spinning the Yarn

Finally, the strands are taken to a machine that can spin up to four ply yarn, in whatever combination is desired, whether it is of different colours of alpaca, or mixing wool with strands of silk or man-made fibres.

A full cone of two ply yarn

Swifting hanks

While some customers want their yarn on large cones, most orders are made into hanks of a specific weight. Here, a swift has been programmed to turn the exact number of times needed to meet the customer's order. The worker then removes the yarn from the swift and twists it into a hank. The finished hank is weighed one last time before being set aside, ready for shipping.

Finished hanks of yarn

The Twisted Sisters Store

After touring the mill, we all got to spend some time in the Twisted Sisters store. There we could browse through shelves of glorious yarns, roving, knit and crocheted garments and accessories, tools and more. We also got to see their wall of award winning yarns on display.

It was a truly fantastic tour! We learned so much about the effort and quality control that goes into making fine yarns - and buy some, too! Many thanks to Kevin and the other wonderful folks at Twisted Sisters for sharing their passion with us.

If you would like to see more photos of the tour, you can visit my flickr set here.

Beautiful Alpaca-blend Yarn

Twisted Sisters Tour video

Here is a short video I made, using footage I took with my cell phone during the tour. I hope you like it!