AUTOMOBILES: Total Cost Minimization

Introduction

The branch of engineering has continually advanced as a result of the ever dynamic technological globe. The preliminary production course of a given automobiles was mostly manual which made it a bit hard in satisfying the requirements of the prospective customers. The best illustration for this can be drawn from the Ford Motor in its first production stages. This can be traced back to the beginning of the 20th century, and the whole production course was handed on dependent for workmanship. For this reason, there was a challenge that was posed to the Ford Company and in particular when the American Society started the acknowledgment and appreciation for the products that were produced by Ford and call for these products began to rise. Ultimately, conversely, the Ford Company incorporated a new technique of automation to their production course. The process made the production much easier for the firm and it started making automobiles at a rate that could be seen a much faster compared to the early manual method used.

This essay is focused on the current and past aspects of engineering automobiles about minimizing the total cost of their production. Furthermore, there is an analysis that has been given for the elements that have clearly illustrated the kind of engineering, production, and given ways through which such factors have impacted the growth of technology.

Auto-insuarance cost minimization

Economic concerns

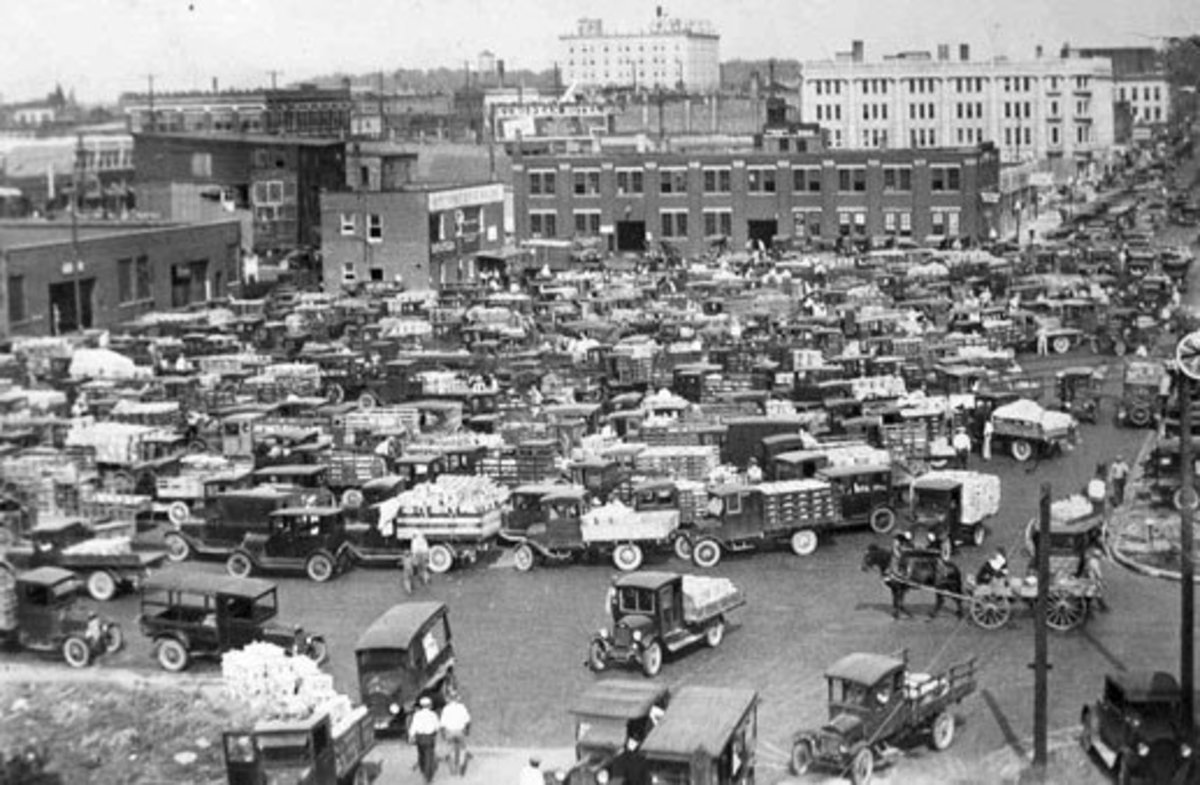

The economic concerns in the past have influenced engineering creativity to vary in significant from what could motivate engineering in the current day. Initially, when the manufacture of automobiles was in its initial phases, and the Ford Motor had dominated the automobile industry, manufacturing and sustaining the request by customers was known to be the main problem. As a result of automation and the given high demand during that time, Ford Motor achieved in opening a total of about 15,000000 assembling plants in the entire of the USA. It has to be agreed that making one car at a time would possibly raise the cost charged on that given car in a way that commercializing such a car would like to become so hard. For one to explain this in an economic state, the production of the initial Ford vehicles dates back in the 1990s. This was seen to be high and costly there as on being that the automation was yet to develop as it was still in its younger stages, and each of the step taken in production process would be mainly done out in a manual way. The cost suffered in any given production was also to be expressed regarding factory expenses, and that has to be spread amongst the small number of items manufactured. During such a time, there was no simulation and computer knowledge. This was a sign that production using manual ways was significantly dependent on experience and reliability in the branch of engineering. Such an aspect was tremendously hard in sustaining. At the end of that kind of production, and when the completed product was taken to the market, their price was so high making it possible to be accessed by those in the society considered to be elite to manage to pay for such cars. In the current day manufacturing, technology has necessitated the manufacture of automobiles to be less expensive. Nevertheless, the rising prices of oil are the main issues in the economy that producers have to deal with. Back in the 1970s, the costs of oil began to rise, and the producers of automobiles had to make engines that could consume at the least little energy while still maintaining the functionality of the engine.

Improvements

The improvements in the engineering sector have been enhanced over the past years. This enhancement can be accredited to the invention of fresh applications that are much taken to be mostly based on the technology of engineering sector. The best example to this is the Toyota motor that has entered the automobile industry in the late 1930s. During this particular time, Ford Motors, and General Motors had by then developed and by then had ruled the automobile industry. In spite of the delay in the entry of Toyota Motor, it was soon able in penetrating the market at a very high rate that had not been witnessed before. Their achievement was accredited to Toyota motor taking up technology and a backward engineering technique. As a result of this embracing of technology that had been taken up by Toyota motor, they could make motor vehicles that were more highly efficient and still at a reasonable price to some their customers. As a result of this, the Automobile engineering was seen leaning in the direction of a low cost of manufacture and still making high-class automobiles. Though, this high rate of automation of the manufacturing process had been followed by some drawbacks. One of the key drawbacks was the extraordinary number of dismissals of the existing manpower. This was taken as a significant challenge to the automobile firms, for example, Toyota Motor Company as it exercised what was referred to as all-time employment for all its workforces. This has not been the instance with Ford Motor Company this is because whenever Ford Company plans to effect dismissals, labour unions interpose and prevent their efforts.

Minimization of total costs in production

Production in the preceding years was described by slowness, delay and the rate at which production was done which could not possibly match the rate of production that is seen in modern day vehicle manufacturing plants. In the state of the production of Ford’s T-model, the demand for this newly manufactured model was high. In spite of the production becoming computerized at some or all levels of their processing and despite this, demands till continued to be a major issue in getting a solution.

For this reason, the clients had no other alternative but had to wait for some months till production would come to completion. Nowadays, automation has completely transformed things, and the expense of production has meaningfully been subsidized. The frequency of manufacturing of automobiles in the regular production lines in renovated Toyota and Ford amenities are much better than they existed in the past Henry Ford Changes the World.

Automation and computerization of the whole production stages have allowed the engineers and the manufacturers to deal with the demand for motor vehicles. Some producers have now involved in the manufacturing of automobiles have raised competition, enhanced the creativity in the manufacturing and encouraging production of motor vehicles that are of high quality. Similarly, this has, in turn, backed the little expenses of automobiles resulting in a large profits and sales. Formerly, firms such as Ford succeeded in selling their products at a higher amount as they ruled the market formerly than other companies. In the incident that one needed to buy any automobile, then the only options were restricted as there existed only very few car producers. In this given way, firms could only define their prices thus covering their expenses. Presently, there is a very high level of competition from different companies, and customers are thus offered with a diversity of alternatives where they can choose from.

Conclusion

From the above discussion, it is seen that the past has laid a basis for the existing day production and engineering. In spite of the fact that challenges categorized the manufacturing of automobiles in the past regarding satisfaction of customers and cost of the product, enhancement in technology has succeeded in dealing with these matters. Computerization of manufacturing is what has contributed to the significant decrease in the pricing of automobiles. This has, on the other hand, facilitated more transactions to be made as clients can easily manage to pay for the subsidized prices. Nevertheless, minimization of costs has led to significant dismissals as most of the-the work that was being done using semi-automated or manually techniques as they have been computerized. Regardless of this drawback, minimization of the total costs sustained in production has critically led to the development of the engineering as a field.