What Is BioDiesel

What is bio-diesel?

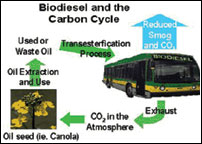

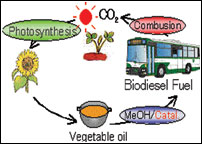

It is a cleaner-burning diesel replacement fuel made from natural renewable sources such as new and used vegetable oils and animal fats. Just like mineral diesel, bio diesel operates in internal combustion engines with little or no modification to the engine. The vegetable oil or animal fat must first go through a process called transesterification before its being used. It is a process of using either ethanol or methanol in the presence of a catalyst, such as potassium hydroxide, to chemically break the molecule of an oil (consisting of tri-glycerides and fatty acids) or fat into an ester and glycerol.

Vegetable oil + alcohol ' glycerin + Ester (bio diesel)

Raw materials

The main raw materials for manufacturing bio diesel via transesterification are vegetable oil (or animal fats) and alcohol (in usual cases methanol is used). The major vegetable oils used till date to produce bio-diesel are canola, soya, palm and a mixture of waste cooking oil.

Non-edible vegetable oil has also been used recently for manufacturing bio-diesel. Major examples of these types are Jojoba and Jatropha. Jatropha curcas has been exploited in many parts of the third world successfully (especially in South America, Africa and some Asian countries such as India and Thailand).

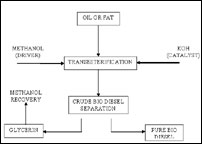

The process

Bio-diesel is manufactured on a large scale and involves a series of steps (figure two). Vegetable oil reactes with methanol using an appropriate catalyst at 70°c (marginally higher than the boiling point of methanol). The mixed products are once again reacted with methanol and a catalyst at 70°c after glycerin is removed (this is a valuable by-product that can be sold at a premium, thus reducing manufacturing costs). Bio-diesel is washed with acid prior to being rinsed with distilled water in a two stage separation process. After drying, pure bio-diesel is available for use.

Why bio-diesel?

It can be used as a pure fuel or is blended in different percentages with petroleum diesel. B20 (20 per cent bio diesel, 80 per cent mineral diesel) has shown significant environmental benefits with a minimum increase in cost for consumers. Using bio-diesel in a conventional diesel engine has been shown to substantially lower emissions of unburned hydrocarbons, carbon monoxide and particulate matter. These reductions increase as the amount of bio-diesel blended into diesel fuel increases. The best reductions in emissions are seen with B100 (100 per cent bio diesel). In addition, the exhaust emissions of sulphur oxides, a major component of acid rain, are essentially eliminated with bio diesel. It can work with new emission control technologies, such as catalysts, particulate traps, and exhaust gas recirculation, all making bio-diesel even cleaner. Nitrogen oxide emissions from it can increase or decrease depending on the engine family and testing procedures. Generally nox emissions from b100 increase on average by 10 per cent in comparison to blends with petroleum diesel.

Low level blends (20 per cent and less) don't seem to require any engine modifications and can provide the same payload capacity and range as diesel. Higher blends and even pure bio diesel (b100) can be used in many engines built since 1994 with little or no modifications. However, in higher blends, attention must be paid to material compatibility and warranty issues (as such, bio-diesel must meet certain international standards such as the astm d 6751 or the en 14214 before being considered for application purposes). Pure bio-diesel does not perform well in cold weather because of thickening due to crystallisation; it needs to have a special system to compensate. Diesel fuels blended with bio-diesel and are better lubricators, which reduces engine wear and tear, making the engine components last longer. The blends have also been shown to clean fuel systems.

As the world is looking for ways to increase its oil independence, bio-diesel seems to be a clear alternative. It promotes sustainability, local farmers' economic livelihood, and the environment.