Kaizen Blitz; Kaikaku

What is a Kaizen Blitz

A Kaizen Blitz (Kaikaku) event is an improvement event that attempts to deliver change and improvements in a short space of time, typically 4 or 5 days. These breakthrough events aim to give you a leap in performance by doing things “now” rather than waiting till later (or never) when things may be done better.

Teams are formed specifically for the purpose of the event and relieved of all other duties during this time, the aim is to concentrate solely on the event and ignore day to day events within the business.

The team; which must include the people from the area in which the kaizen blitz are focusing, are empowered to make any changes they feel necessary without having to constantly ask for permission for every small change.

Kaizen Blitz Training

Kaizen Blitz Benefits

The main benefit of any Kaikaku or kaizen blitz is the speed of improvement; typically 20% to 100% improvements in productivity can be achieved in the space of a week. Kaizen blitzes that I have personally facilitated have reduced lead times from several weeks to just one or two days and have reduced factory space by 50% or more. These kaizen blitzes are capable of providing the benefits of lean manufacturing or 5S benefits in a very short space of time.

What can you do with a Kaizen Blitz?

A Kaizen Blitz will typically have a specific focus or goal, otherwise how will you know what it is that you are trying to do or if you have achieved it?

Typically these blitz events cover just a few main areas;

- 5S Kaizen Blitz to introduce 5S principles into an area.

- Layout improvement Blitz; reorganize a facility to make things flow smoothly and more efficiently.

- Quality Improvement Blitz; focusing on reducing defects within the area.

- Lead time reduction blitz; will involve aspects or reorganising and planning to reduce lead times.

Of course your blitz could have any objective such as improving efficiency by 20% or reducing space used by 50%. But be as specific as possible and plan ahead.

Kaizen Blitz Video Clip

Planning a Kaizen Blitz

A Kaizen Blitz does not just happen! There has to be a significant amount of preparation prior to any blitz event, a typical preparation may be;

- One day diagnostic visit to select the area, review measures, and discuss expectations.

- Review period during which measures are firmed up and data collected.

- Team selection and training, normally 2 to 3 days of training in process mapping, 7 wastes, 5S and quality tools. This should include actually mapping the process and agreeing the objectives of the forthcoming kaizen event. Concluded with a presentation to management and their agreement.

- Include the supervisor / team leader (must have) and management of the area in the team where possible to ensure their buy in for the improvements to be made.

- Preparation period; Data collection, stock building (to cover customers during kaizen blitz period), ensuring support staff availability, purchasing any tools required, etc.

- One day check by the facilitator prior to the event to ensure all will be complete prior to the actual event.

The better your preparation the better the end result of your event and the fewer problems that you are likely to encounter. Proper Preparation and Planning Prevent Poor Performance (The 6Ps) is a forces term that very much applies to this situation.

Kaizen Blitz Team

Who should be a member of your Kaizen Blitz team?

Well your team will require a leader or facilitator whose job it is to help the team achieve the objectives of the blitz. Typically this will be a Lean Consultant or Trainer with significant experience in running these types of events.

You must also include the team Leaders and supervisors of the areas as these are the people that will have to live with and make the changes work on a day to day basis. If change is thrust on them you will have a significant amount of resistant, however if they create the change the support you can gain can be tremendous.

Also include a number of people that work in the area, all if feasible.

Additionally you want people from maintenance, facilities, engineering, design, sales; in fact any relevant discipline that could add value to your team.

Should you use management in a Kaizen Event?

Using management in the teams can be detrimental, many managers want to take over and drive things in the direction that they want. You will also find that many staff will clam up and not contribute preferring just to follow the lead of management.

I prefer to use management within the approval process having the team make presentations / proposals regarding what they intend to do and gaining approval from the management.

Running a Kaizen Blitz

Kaizen Blitz Process

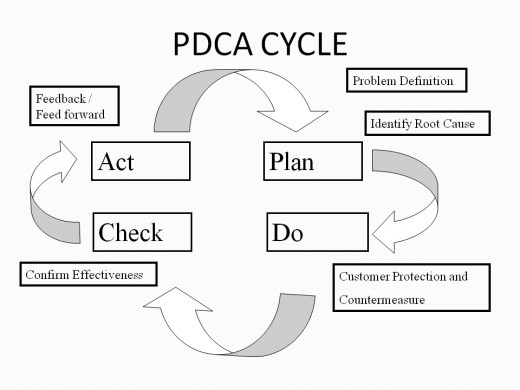

The process followed for Kaikaku will be based around the Shewhart or Deming cycle (PDCA cycle), with the facilitator (consultant usually) leading the workshop. The idea will be to work through the cycle several times making whatever improvements that the team agrees upon.

Usually the first day will be spent reminding the team about the process, seven wastes, 5S and other tools followed by review of the process maps already created and the improvements expected for the kaizen blitz.

The main team may be split into sub-teams to investigate different aspects of the objectives for the blitz depending on the size of the area to be improved. Each Blitz is very different as each area is different as are the objectives.

The important thing is to keep momentum, do not allow the team to flounder or get stuck. The aim of the blitz is to make as many improvements as you can. Whilst the team is waiting for a machine to be moved by maintenance overnight they can review the stock quantities currently used and so on. There are a million things that the team could consider and improve in any blitz event.

Typically things like machine movements and the like will be done overnight to ensure a clear run for the following day. Changes to layouts and process should be tested by the team to highlight any problems and new standardized ways of working should be agreed and documented.

At the end of the kaizen blitz event the team should present back to management what has been achieved with expectations of savings and factual data.

Kaizen Blitz Products

Kaizen Blitz Follow Up

The Facilitator should return after usually a month to see the results of any outstanding actions with the full team. Outstanding actions are things such as machines that could not be moved during the blitz event itself or the purchase of necessary tools and equipment.

The new processes should be reviewed along with the measures and objectives and any outstanding problems addressed.

This day long is usually repeated over a period of 3 months or so depending on the progress made and the number and severity of outstanding actions.

Kaizen Blitz Training DVD

Kaizen Video

Sustainability of Kaizen Blitzes

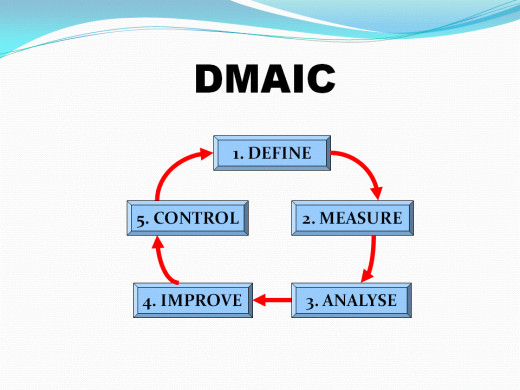

The biggest problem with any Kaizen Blitz is sustaining the gains made, it is very easy for things to slip back to the way they were once the team has been disbanded and focus has shifted elsewhere within the organization.

Too often a kaizen blitz is a one off event without the support of a continuous improvement culture with which to build on the gains made by the original team. With no ongoing Kaizen support for continual improvement or problem solving the improvements dissolve as problems occur or customer expectations change.

Supporting a Kaizen Blitz

The kaizen institute and other lean manufacturing consultants can be approached for help with running your kaizen blitz, you should remember that generally speaking the more experienced more able consultancies will charge you far more but the returns should also be much higher.

Government bodies and support groups like the manufacturing advisory service will run many kaizen events every week, these are often subsidized by the taxpayer so their cost to you is much less. Business support groups and even universities are also worth approaching; the institute for manufacturing at Cambridge University can be of great help for instance.

lean manufacturing tools can give information about the many tools available within lean manufacturing as can the article on quality tools if you need help with problem solving and continuous improvement.

If you have any questions or comments regarding having a kaizen blitz or any other questions about lean manufacturing please use the space below.