Project Risk Management

Risk Management Strategy and Process

- Risk identification:

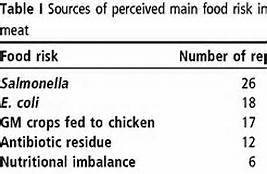

Cost – From working in the meat industry, a cost constraint is a when there are budget issues with in the project. The budget is constantly monitored to assess how a timeline or changes of scope. If the budget is not carefully monitored then the project could go off track due to unexpected costs. Management is constantly monitoring the budget to make sure there are no cost overruns because then they think the project is not on target. Budget cuts are a form of the reconstruction process. Budget cuts are a sure sign to the project manager to monitor the budget and try to stay under to complete it on time.

Scheduling - Scheduling during the project can also be a constraint especially if the value of time is involved. The author has seen by experience that scheduling at the meat facility is very important because meat has a shelf life and if it is not used by that date than it has to be thrown away. Listeria can grow as the meat gets closure to the date. Scheduling becomes an issue when the parts for a certain machine do not arrive on time or if it takes longer than anticipated to get a manufactured part or the manufacturing of the part is longer than expected. Such as the swabs that are used to do the testing, if they are not in the facility when we need them, then that could delay the collection of data and that could delay whether the project goes forward or gets stopped. If the employees do not have the swabs to use then listeria could show up on a machine and the contaminated machine could cause a recall because the swabs where not done in proper sequence. Other problems could be that the stakeholders loose interest and outside interference like sick employees or employees that leave and have to be replaced.

Performance – In the experience of the author, the production run suffers and more money must be allocated because of color of the meat if it is not cooked correctly, temperatures not monitored by the team leaders or employees. The process is not monitored and thus the project suffers.

Quality – Most meat facilities have a strict policy that has been set by the corporate office. If the standards of the testing of swabs, sanitation procedures not followed and employees not following GMP’s (Good Manufacturing Processes) then Listeria is found to be present and standards are lessened.

Project Summary

- Requirements – What will the needs be for the project of preventing Listeria from the packaging and how to regulate the cook temperatures. How many swabs to take and where on the machine to swab

- Schedule – Morning meetings to assess production numbers and issues that happen during in the nighttime production run, government swabs and when to implement them or to change the schedule if a certain meat is about to go out of code date

- Constraints – Cost , Scheduling, Performance and Quality

Risk Identification

The identification of the risk is a very component part of the process. The project manager and stakeholders need to brainstorm what is happening, why it is happening, and the root cause and how to create systems that will lessen the likelihood of the consequences occurring.

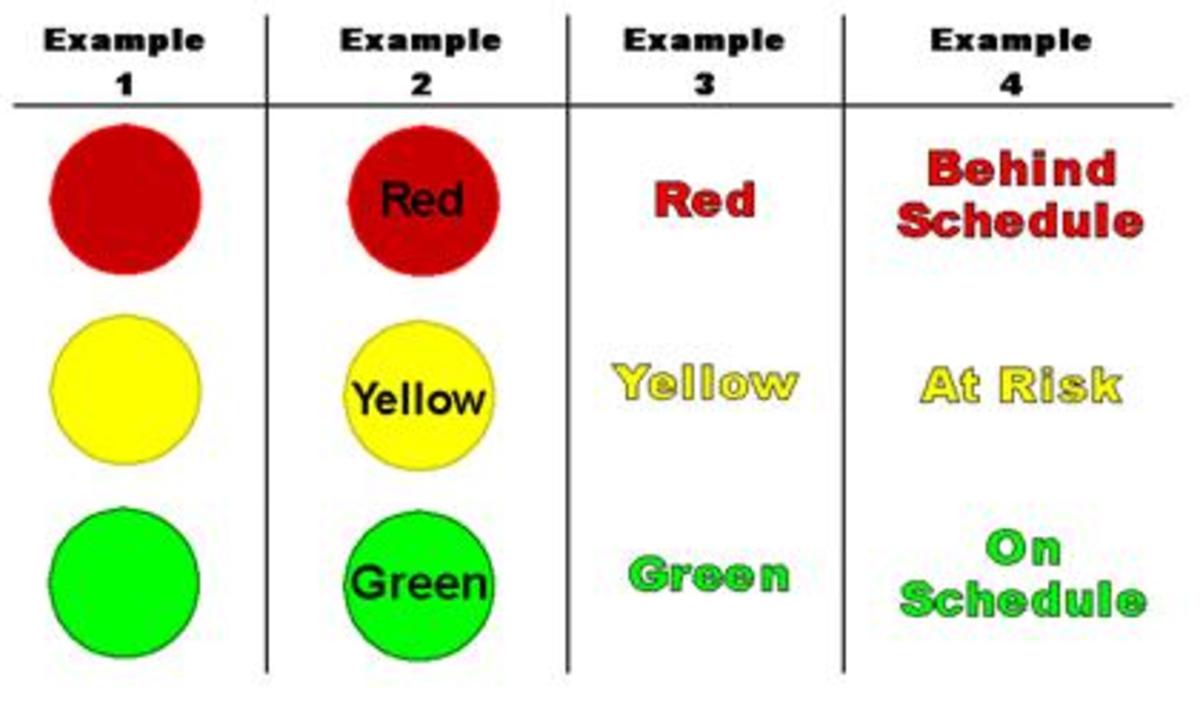

Risk Tracking

One of the risk audits used in food safety for manufacturing plant is an HACCP (Hazard Analysis Critical Control Point) audit. “They require that we analyze preparation methods in a rational, scientific manner to identify critical control points and to establish critical limits and monitoring procedures,” (safe food management, (2013), p.1). It helps keep the food borne pathogens from forming on the machines, the packages and in the hot dogs. Daily monitoring helps the food industry control these items and make sure that the oven temperatures are safe and that the pathogens are safely removed in the cooking process. It is very important in the manufacturing industry to apply this audit to keep down the risks. It helps keep the risks monitored to keep a proactive stance instead of a reactive one. The project manager can monitor and review an audit so that it does not become a crisis situation.

Information can be obtained by going to

- Safe Food Management - Auditing

Information that will explain rules and reasons for safe food management that the meat industry follows.

Risk Mitigation Planning

The risk mitigation planning process includes forming to sections. One is to identify all of the different activities, to create the steps and calculate the how big of the probability of impact. The second is to form a Contingency plan to solve or prevent the risk if it happens.

Project management for the meat industry

The items listed in this is only a part of what the meat industry must go through to have a project managed. It has to make sure that procautions are maintained so that the meat does not have anything in that it shouldn't like Listeria, or any other germ that might be present if the people doing the project do not watch. It is very important that all policies are followed and the projects be planned out and monitored to make that it all flows well and the project is successful and the product does not get harmed.