5 Whys Analysis & Root Cause Analysis - A Lean Six Sigma Tool For Problem Solving

5 Whys Analysis

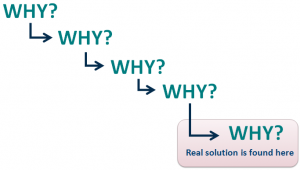

One of the key methods of Root Cause Analysis is 5 whys Analysis. This is a technique initially developed by the Toyota Production System in the 1970’s to identify key issues in a manufacturing process to increase productivity by minimising rejects. 5 whys analysis is much touted in the worlds of Lean and Six Sigma as a key tool because it is easy to use and remember and takes very little education or experience to start getting good results.

How Does 5 Whys Analysis Work?

In essence 5 Whys Analysis works by asking the question ‘why did this happen?’, then when you have identified a cause you ask “why did that cause happen?’ and you keep asking why the cause happened until you reach a fundamental cause or reach a cause that you have no control over, if you have no control over the cause you will probably have no control over the cause of the cause so it’s time to stop. The general rule is that 5 iterations of why will get you to the root cause of the problem, hence 5 Whys Analysis, however depending on the issue you may reach the root cause in 3 or 7 or more whys.

Why Only 5 Whys?

There is nothing to prevent you asking why indefinitely but in my experience if you go much beyond 5 whys you may be looking at the issue in too much detail and could find yourself going on indefinitely.

Conversely if you are finding your root cause in much less than 5 whys there is a chance that you are not looking at the issue in enough detail and the root cause you have identified may not be a root cause at all. In this instance continue to ask why and if you cannot take that line of enquiry any further you may have actually reached the actual root cause after all or you may just have the wrong line of enquiry in which case you should start the 5 Whys Analysis again and look at different causes.

A key rule is to use your common sense if you are coming up with some crazy causes then you are probably on the wrong track and should either backtrack a level or start again.

A Working Example Of 5 Whys Analysis

Problem - One of our most important clients is unhappy...

1. Why is one of our most important clients unhappy?

- Because our deliverables haven’t been of sufficient quality.

2. Why have our deliverables not been of sufficient quality?

- Because we haven’t had enough time to work on them?

3. Why have we not had enough time to work on the deliverables?

- Because we don’t have enough people to work on the activities.

4. Why do we not have enough people to work on the activities?

- Because our resources are being dragged on to other projects?

5. Why are our resources being dragged on to other projects?

- Because there is no prioritisation of work going on so we can’t identify what the most important work packages are.

So the root cause here is lack of prioritisation of work. A solution could be to implement a portfolio office to measure, track and prioritise work.

Advantages and Disadvantages of 5 Whys Analysis

The key advantage of 5 Whys analysis is that it is ultimately a very simple tool that allows you to very quickly get to the root cause of a problem. However, a key disadvantage is that it is essentially a very simple tool and may not be suitable for complex problems that may have a multitude of causes. The 5 Whys Analysis shouldn’t be confused with an in depth analytical tool and the more complicated a situation is, the more likely that 5 Whys Analysis will lead you the wrong way.

If you want to learn more about 5 Whys Analysis and Root Cause Analysis

Does 5 Whys Analysis work if there is more than one cause?

If the problem is complex 5 Whys Analysis may not be suitabe so you should use a more sophisticated approach such as full Root cause Analysis or Cause and Effect Analysis which will look at the problem in much more detail. However, it is always worth doing a quick 5 Whys analysis as it is a quick and easy approach. To maximise the chance of you getting to the correct root cause you should apply a quality test to each why that you ask. So always ask:

- Is this the most important cause?

- Does this cause actually lead straight to the problem?

- Are there any other contributing factors?

These questions will help you get to the real root of the problem more effectively.

If you think there may be other causes, simply apply 5 Whys Analysis to the same problem but define a different cause at the first why and see where the analysis takes you. Do this as many times as you feel necessary to complete a more detailed picture of what the real root cause or causes might be. You may well end up with a more complicated picture but may identify more causes that you had previously missed.

Summary

5 Whys Analysis to Root Cause Analysis is a valuable tool as it is easy to use and can get you good results very quickly. However it is not always suitable for complex problems.

If you have used 5 Whys Analysis before and found it useful or have any questions please leave a comment.