The History and Invention of the 3D Printer

3D printing, sometimes referred to as additive manufacturing (AM), is a method of manufacturing products whereby material is added together or "built up" using a computer controlled print head to form a product or part. This technology is often seen as the opposite of traditional machining techniques that use a variety of tools to remove material from a block or slug to form the product or part. 3D printing is also generally seen as a type of automated or robotic manufacturing. In the 1980s society had pushed back the materials and mechanisms limit just enough to pave the way for this new type of technology to be created.

The first type of 3D printing that was invented is called stereolithography (SLA). This method of manufacturing is a process that was first conceived by Charles 'Chuck' Hull in 1983. Hull's process used a laser to concentrate a beam of ultraviolet light onto a pool of liquid photopolymer. This beam of ultraviolet light caused the photopolymer to solidify upon contact. A three dimensional object could be created quickly and easily when the laser was used to solidify successive layers of the photopolymer.

In 1986, Hull obtained a patent for his 3D printer design. That same year, Hull founded 3D Systems, Inc in order to commercialize rapid prototyping through the use of his invention. This invention marked the beginning of the 3D printer industry. And for his contributions, Charles 'Chuck' Hull was recently inducted into the National Inventors Hall of Fame and is known to many as the Father of 3D printing.

In 1989, another man named S. Scott Crump filed a patent for a new 3D printing process which he called 'fused deposition modeling' or FDM. In the same year that Crump filed his patent, he and his wife Lisa started their company Stratasys, Inc., to produce and sell this new rapid prototyping machine. This technology used a heated nozzle to melt and inject a material onto a surface where it would solidify in multiple layers ultimately forming an object. Since Crump was trying find a way to rapidly create prototypes of new products, his invention originally used ABS plastic filament as a raw material. Today, the 3D printers produced by Stratasys, Inc. can utilize a wide variety of thermoplastic materials to produce complex three dimensional objects with different properties.

At about the same time that both Hull and Crump were hard at work inventing their 3D printing processes, another man by the name of Dr. Carl Deckard also conceived of a new three dimensional printing process [Texas A&M, 2012]. Working under the sponsorship of DARPA in the mid 1980s Dr. Carl Deckard and his colleague Dr. Joe Beaman devised a technique similar to Chuck Hull's original design but differed in that it used a laser to fuse powdered plastics, glass, and metals together.

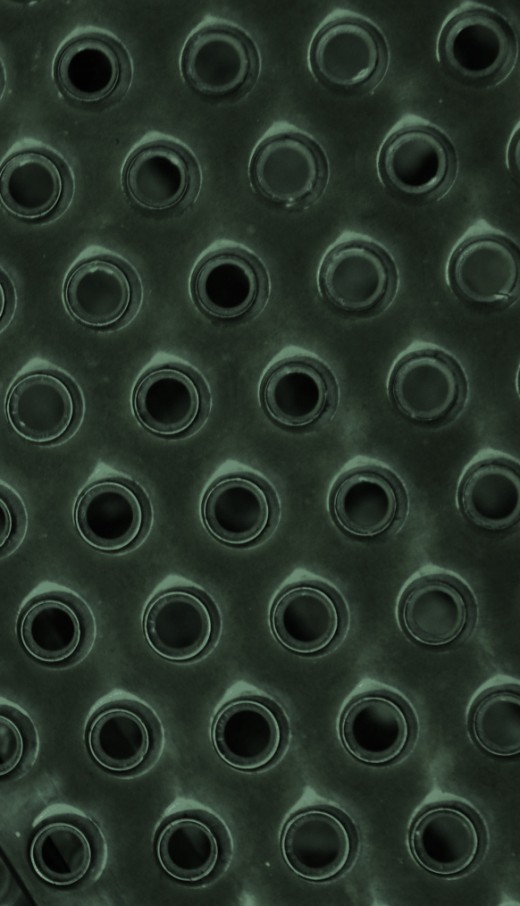

Deckard's process is known as selective laser sintering or SLS and is still used in many types of 3D printers on the market today. In fact, printers that use the selective laser sintering (SLS) process are often considered to be superior to stereolithography (SLA) and fused deposition modeling (FDM) because the 3D printer does not have to construct 'support structures' allowing for the creation of more complex products than what the other processes can create. In 1986 Deckard and his associates formed Nova Automation (which was later renamed to DTM Corp), the company which helped commercialize the SLS printing method.

As we can see, from a historical perspective there were really only three major players that built the 3D printing world. Eventually Hull's 3D Systems, Inc bought out Deckard's DTM Corp and now stands next to Crump's Statasys, Inc as a world leader in this technology. Not long after these companies were formed, many more companies followed in an effort to cash in on the growing interest in 3D printers. And as we'll soon find out, the industry was about to give everyone more affordable choices for society to choose from.

From Rapid Prototyping to Primary Manufacturing and Mass Customization

When 3D printing technology was first created, the initial goal was to develop a way to rapidly prototype new ideas and products. In a typical scenario before 3D printers were available, a prototype would need to drawn up by an engineer and then sent to a machine shop to be created using traditional techniques. This process was labor intensive, expensive, and could take weeks or even months to complete depending on the complexity of the part. If the prototype failed to meet the designer's expectations it was back to the drawing board to start the process over again.

By the early 1990s 3D printer technology was proven to be commercially viable and did a great job at meeting the demand for faster and cheaper prototyping methods. For example, the 1980’s American auto industry was struggling to compete with cars being manufactured by the Japanese. 3D printing came along and gave Americans the advantage because it made the process of designing new cars significantly easier than before. The result was cheaper cars that could be designed and tested much more quickly than what was possible in the past. 3D printers made it feasible to develop prototypes of parts in a matter of days as compared to weeks or months.

However, it wasn't until the late 1990s that 3D printers started to be used for things other than just creating prototypes. As the technology was refined and the materials that the machine used were made stronger, these printers eventually became capable of producing finished products ready for retail sale and use by a customer. Furthermore, 3D printers offered another clear advantage over traditional mass production techniques at this point in time: the ability to create customized products at a rapid rate. An early adopter of the technology has been the health-care industry—a field in which mass customization is important because every patient is different. There is no such thing as a 'one size fits all' prosthetic. For example, millions of hearing-aid shells have been 3D printed from scans of patients’ ear canals [3D Systems, The Economist, 2013].

The Rise of the Consumer Grade 3D Printers and 3D Print Shops

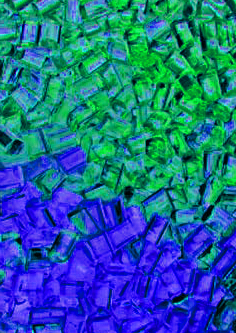

Due to increased market competition and a 2009 expiration of Crump's original patent for the fused-deposition modeling (FDM) technology, anyone can now purchase their very own working 3D printer for less than $1,000 (SLS and SLA printers are still out of reach for most Americans). These printers come from a variety of manufacturers but are all capable of printing out plastic parts that can be used for nearly any purpose. As this industry continues to improve its printers, we will start to see consumer grade SLA and SLS printers being marketed to the do-it-yourselfers and hobbyists.

Many 3D printer manufacturers also bundle the devices with the software necessary to create anything you can dream of. Much of the software and plans for these printers are set in an open source format making it possible for anyone to use or improve existing designs for useful products. In addition to this, there are online communities of 3D printer enthusiasts who trade CAD drawings and work on joint projects together.

If you're still not ready to shell out the cash for your own home 3D printer, you can still have something printed by taking your plans to one of the many 3D print shops that are popping up all over the country. Recently, the United Parcel Service (UPS) announced that nearly 100 of stores will offer 3D printing services to the public [Engadget, 2014].

References and Further Information

"1983-2013 Celebrating 30 years since the first 3D printed part" 30 Years of Innovation. 3D Systems, Inc. Web. 23 Sept. 2014. <http://www.3dsystems.com/30-years-innovation>

"3D Printing Scales Up" Technology Quarterly. The Economist Newspaper. 7 Sept. 2013. Web. 23 Sept. 2014. <http://www.economist.com/news/technology-quarterly/21584447-digital-manufacturing-there-lot-hype-around-3d-printing-it-fast >

"Charles Hull: Stereolithography (3D Printing)" National Inventors Hall of Fame. Web. 23 Sept. 2014. <http://invent.org/inductees/hull-charles/>

Fingas, Jon. " UPS now lets you use 3D printers in nearly 100 US stores" Engadget. 22 Sept. 2014. Web. 23 Sept. 2014. <http://www.engadget.com/2014/09/22/ups-3d-printer-expansion/>

"Gartner Says Worldwide Shipments of 3D Printers to Grow 49 Percent in 2013" Newsroom and Announcements. Gartner, Inc., 2 Oct. 2013. Web. 23 Sept. 2014. <http://www.gartner.com/newsroom/id/2600115>

"History of Statasys, Inc" Funding Universe. Web. 23 Sept. 2014. <http://www.fundinguniverse.com/company-histories/stratasys-inc-history/>

Kennedy, Pagan. "Who Made that 3D Printer?" The New York Times. 22 Nov. 2013. Web 23 Sept. 2014. <http://www.nytimes.com/2013/11/24/magazine/who-made-that-3-d-printer.html>