Total Productive Maintenance TPM

Development of TPM

What is TPM (Total Productive Maintenance) and how does it compare to other types of maintenance systems? To understand TPM we need to understand from where it has developed and why.

After World War2 the Japanese manufacturers spent considerable time studying the American manufacturing companies and how they made themselves more productive to support the war effort. One of these companies (Nippondenso; a supplier to Toyota) investigated the efforts that US manufacturers were making in moving from breakdown maintenance to preventive and predictive maintenance systems.

They combined what they learned from the US companies about maintenance with what they were doing with developing team working as a forerunner to TQM (total quality management) and used what they learned to develop what we now call today TPM; Total Productive Maintenance, a maintenance system that involves all people within the organization.

TPM was not implemented in the USA until around 1987 when Kodak implemented it within a plant in Tennessee.

TPM Total Productive Maintenance

Traditional Maintenance (Run to Failure)

Traditional western maintenance falls under the responsibility of the entity known as the maintenance department.

The maintenance department is usually located as far away from production (and management) as possible and are an “on call” service for production when a breakdown occurs.

They inform everyone that they do as good a job as they can with a lack of spare parts, not enough people and with no access to machines that are never released by production!

Maintenance is purely fire fighting, with any “real” maintenance being done during the annual shutdown – if the company can afford to shut the line down!

Operators have no involvement with maintenance, operators run machines until they break and maintenance are then responsible to fix them.

While this may be a little "tongue in cheek" description it is not far from the truth for many companies and I have certainly had the misfortune to deal with these types of "traditional maintenance" departments in the past. This is hardly an ideal way to maintain reliable production equipment and is why many companies seek to improve what they are doing.

Preventative maintenance

Preventative maintenance is the next step in the evolutionary process, we take steps before the breakdown occurs to prevent it from happening. Much like making an oil change on your car or taking it in to be greased up.

Far too often however releasing machines for scheduled maintenance becomes an issue for busy production departments and the maintenance is either skipped completely or is rescheduled for a later date, often in a shut down period when a busy maintenance department has to supplement its manpower with subcontracted labor at huge additional cost.

Sometimes however we do not consider the economics of the situation and we take actions long before we need to costing the company far more than we need to.

When we look at most preventative maintenance systems they are based on the use of experts within the maintenance department and the people that actually run the machines only become involved when the machines break down and they have to contact maintenance.

TPM and Predictive Maintenance

Predictive maintenance

Predictive maintenance is where we look at failure history and use other methods such as vibration analysis and infrared inspection to predict failure enabling us to take action when it is really needed, not too far in advance of real need - after all changing oil on your car every 1000km is not going to make any noticeable difference in the life of the engine compared to what the manufacturer recommends. By doing analysis however you may find that you can operate twice as long as the manufacturer recommends without detriment!

The main factor in deciding whether to use a predictive vs preventive maintenance is that of cost, if you believe that the added costs of using the predictive maintenance will be greater than any savings you make over preventive maintenance then stick with the preventative program.

It is rare that any company would implement only predictive maintenance methods, most companies would implement a combination of preventive and predictive maintenance depending on cost analysis. Again this method solely employs experts in the maintenance of your processes.

TPM Video

TPM

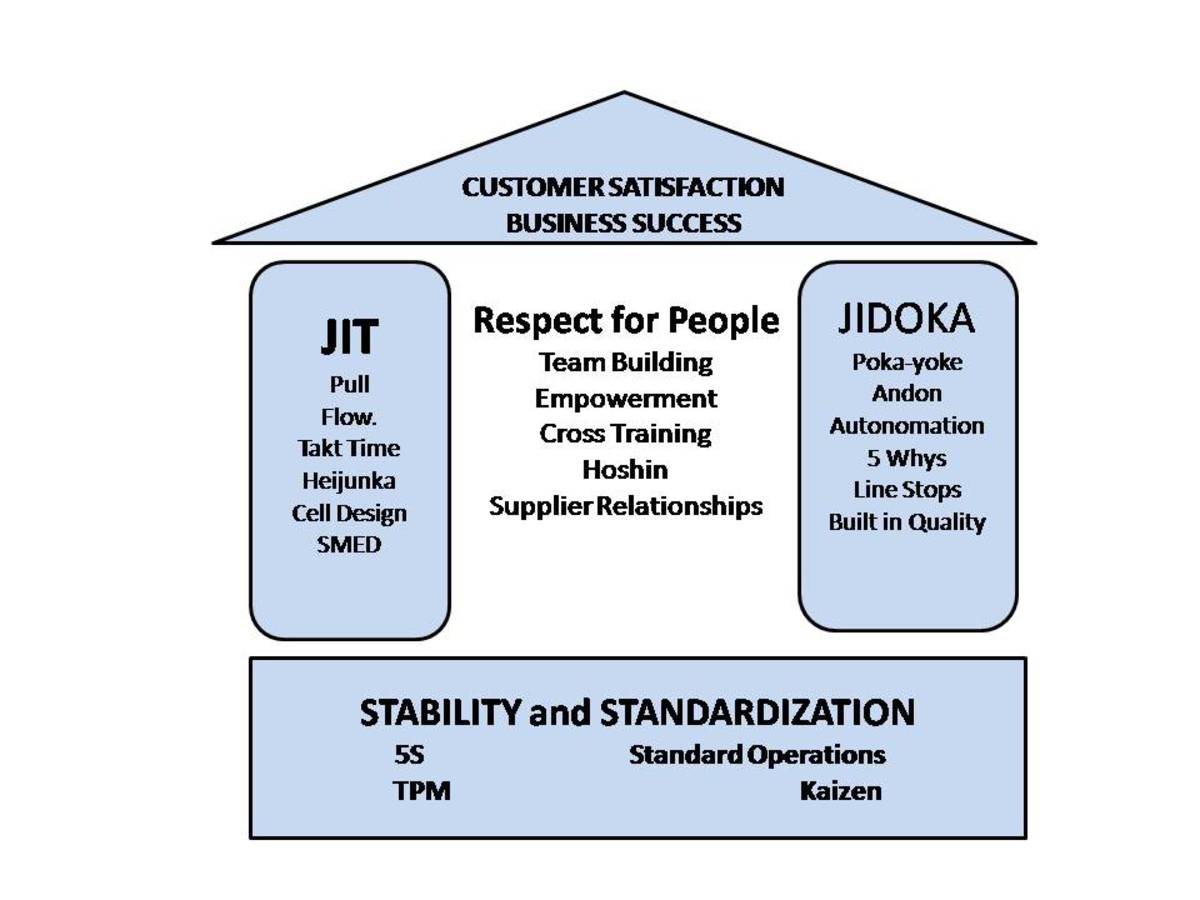

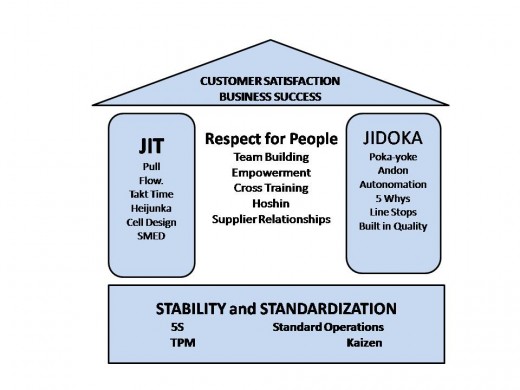

Total Productive maintenance (TPM) is an integral part of lean manufacturing; after all how can you implement just in time manufacturing, reduce work in progress and a host of other improvements if you can’t rely on your machines and equipment.

TPM is productive maintenance with the involvement of everyone in your organisation from the senior management down to the operator. Productive maintenance differs from other maintenance programs in that it seeks to ensure that we make best use of and extend the working life of our equipment by looking beyond breakdowns to issues such as quality, performance and availability whilst not forgetting safety and of course the economics of what we do.

TQM and TPM

Total productive maintenance shares much with TQM and can be thought of the machine and equipment equivalent of TQM. Both require the involvement of all within the organisation. They both value the use of the operator rather than relying on an expert to direct change and improvements. By spreading the load we allow the specialists to do more complex tasks whilst the operator conducts the more routine tasks. Both are very much focused on prevention of problems rather than dealing with issues after they have occurred.

Aims of TPM

TPM aims to reduce the six big losses through a measure known as OEE (Overall equipment efficiency);

Availability;

- Breakdowns – Time lost due to any unplanned stoppage in excess of 10 minutes.

- Changeover and Adjustment Losses – The time taken to go from the last good part of one batch to the first good part of the next.

Performance;

- Minor stops and idling – Lost production due to short stops and adjustments that take less than 10 minutes.

- Reduced Speed Loses – Running the machine at less than its design speed.

Quality;

- Defects – Scrap and rework caused by the machine

- Start up losses – The number of defective parts produced during startup.

The OEE calculation is made by multiplying Availability x Performance x Quality as a percentage. An initial OEE measurement is normally in the order of 50 to 60%, world class is normally thought of as being around the 90% mark although this varies industry to industry.

With the focus of OEE not just on preventing breakdowns but on improving quality and removing delays it also encompasses the use of lean manufacturing tools such as SMED (single minute exchange of die) to reduce the setup times and losses and PokaYoke to prevent defects from being produced.

Corrective Maintenance

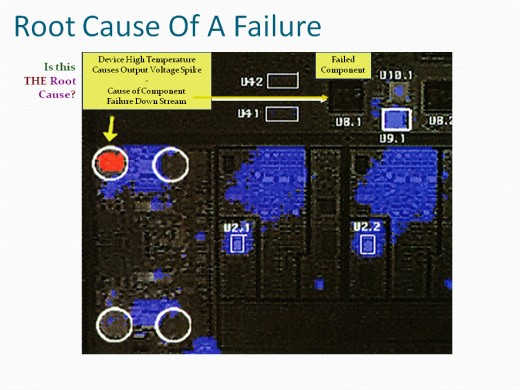

TPM (Total Productive Maintenance) expects us to continually improve in much the same way as any other lean manufacturing tool or quality initiative, with TPM we need to look constantly at finding ways to improve our machines to make them easier to maintain and more reliable.

Kaizen teams should review maintenance records and operator suggestions for ideas to improve reliability as well as making improvements such as making the workings of the machines more visible using perspex guarding and improving access to make any required maintenance easier to perform and problems easier to diagnose.

Maintenance Prevention

One of the roles of the maintenance department now is the design of maintenance free equipment that does not break down, or if it does break down it can be repaired very easily.

Through analysis of maintenance data they can work with the equipment designers to improve future generations of machines to ensure greater reliability and ease of maintenance and repair.

TPM Autonomous Maintenance

Autonomous Maintenance

Autonomous maintenance is one of the biggest aims of TPM, your operators become responsible for independent maintenance of the machines rather than running them to breakdown and passing them to the maintenance guys to fix.

The operators become responsible for the day to day maintenance such as tightening bolts and lubrication and basic inspections thus ensuring that the machines remain in optimal condition and problems are highlighted before breakdowns occur.

This also releases the maintenance technicians to work on other maintenance work such as maintenance prevention.

Adoption of TPM into the Toyota Production System

Toyota adopted TPM very quickly along with 5S and other lean tools as part of their Toyota Production System (TPS) to ensure that they had machines and processes that could be relied on to provide the customer with what they wanted. Thus TPM has become an integral part of any Lean initiative.

TPM a Foundation Stone of Lean

TPM and 5S

5S is the methodical process for both organizing and standardizing your workplace within Lean. Like TPM it involves everyone within the workplace.

TPM follows many of the requirements of 5S and in fact it would be hard to implement TPM without also implementing 5S. 5S should be your first port of call when beginning your drive to implement TPM; together they provide your company with a solid foundation on which you can build future improvements.

TPM a Final Word

I hope that this has answered your questions on Total Productive Maintenance (TPM); please feel free to leave any comments below or ask any questions.