What Is a Lean Six Sigma Black Belt?

Overview

Lean Six Sigma certifications follow the example of the martial arts, assigning belts of different colors to identify progressive levels of expertise in Six Sigma.

Different organizations vary in the recognition of those merely familiar with Lean Six Sigma concepts, but experts in Six Sigma are universally called Six Sigma Black Belts.

Six Sigma White Belt / Yellow Belt

The Lean Six Sigma white belt or yellow belt is someone who has been introduced to Six Sigma and Lean Six Sigma concepts. This designation is most commonly used with shop floor employees and customer service personnel who perform the day to day work in an operation. By learning the basics of Lean Six Sigma, employees gain an appreciation of the need to collect and report accurate information and following new business processes. The term red belts can be used to refer to either green belts or those with a cursory level of understanding of Six Sigma.

Lean Six Sigma Green Belt

Lean Six Sigma green belts are the mid-level employees trained in Lean Six Sigma principles, statistics and process documentation over several days. Green belts are qualified to lead small projects with the help of team members or white belts and yellow belts that are completed in a few weeks and have limited scope. Green belts are also the mid-level managers and workhorses of Lean Six Sigma Black Belts.

Six Sigma green belts hold this certification in conjunction with their primary job. An engineer, accountant or shop facilitator would be trained as a Six Sigma or Lean Six Sigma green belt. Green belts lead small Six Sigma projects or support major Six Sigma initiatives led by Lean Six Sigma Black Belts in addition to their day jobs. Green belts earn their certification by either leading a small project under the guidance of a Black Belt or working on a project for a Lean Six Sigma Black Belt.

Lean Six Sigma Black Belt

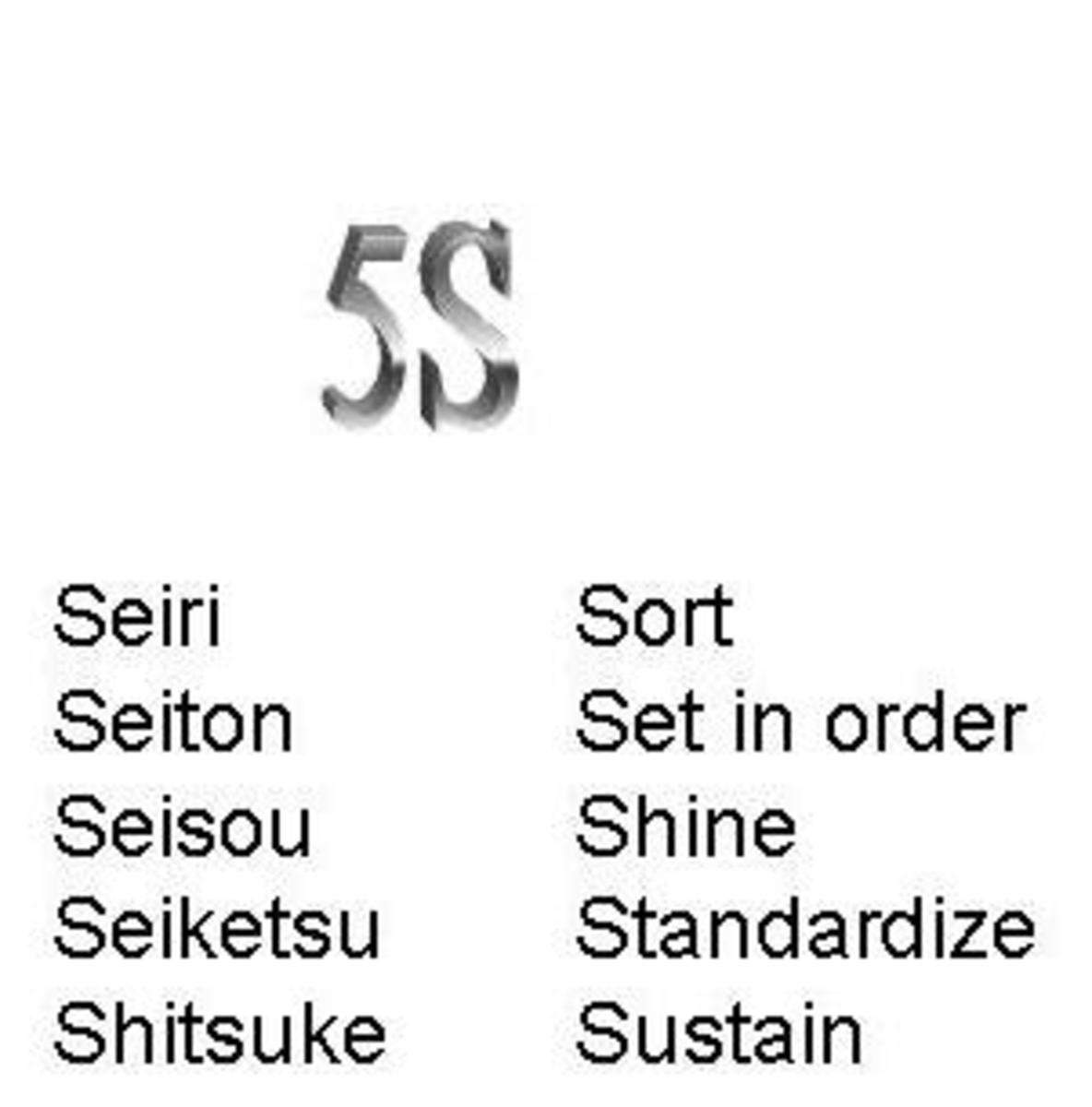

Lean Six Sigma Black Belts or LSS black belts are the experts in Lean Six Sigma. They take several weeks or months of training in Six Sigma quality, lean manufacturing, statistics, project management and leadership. Lean Six Sigma Black Belts lead major projects in an organization that change factories, work sites, business processes and production lines.

Lean Six Sigma Black Belts may work as consultants for small businesses and non-profits. Black Belts often train green belts, yellow belts and white belts. Unlike the lower belts, Lean Six Sigma is the primary job of Black Belts. Lean Six Sigma Black Belt certification is granted after a Black Belt leads and completes a major process improvement initiative under the supervision of another Black Belt or a Master Black Belt.

Lean Six Sigma Master Black Belt

Lean Six Sigma Master Black Belts may be often hired by large companies to implement Lean Six Sigma across the board or as consultants in implementing Six Sigma programs across a distributed workforce. Their job includes training Lean Six Sigma Black Belts, changing corporate cultures and implementing quality processes where they have not existed before. Master Black Belts may be corporate quality managers, senior managers or consultants.

Lean Six Sigma Champions

Champions are the managers who make resources available to Black Belts. They may or may not be master Black Belts but do mentor them. Without a champion in management, there is little will by employees to radically change business operations or sustain the gain, following revamped processes over the long term. Lean Six Sigma Black Belts may become Champions as they rise through the management chain.