Why Assortment Planning and Capacity Development is Vital For Survival of Retail Chains

Background

Assortment planning is deployed by many retailers across product segments in order to periodically update specific product assortments, add new products and delete slow sellers as a timed response to variations in consumer demand or new product offerings. Do you use personal judgement or rely on hard data in order to predict consumers’ response to assortment changes.

When an organization is keen to develop capacity for results, there are a number of factors that need to be taken into consideration. Today’s marketplace is largely data driven and the best performing players across most sectors are those who have recognized the need to deploy efficient tools and methodologies in synthesizing and analysing key data.

Key Factors That Determines Capacity Development

There are some key factors to consider when plans are in the offing to develop capacity within your organization and they are examined as follows:

Matching Resources

When considering how to match resources, there is a need to consider the present capacity of the organization in terms of ability to muster needed funds. The present stage of development of the organization, ability to muster funds, and at what level, and the match between expected outlay and organizational strength, needs careful consideration.

A firm with an annual turnover of 1 million Euros have no business investing approving a budget of 500,000 Euros for capacity development. There must be consideration for cost-effectiveness and optimization of input and returns. For any entrepreneur in a hurry to develop capacity, any mismatch will be fatal.

Existing Manpower

A manpower audit is crucial when planning to develop capacity within an organization. What are the skills available, what can they do, what is needed and what level? These are all crucial questions to answer and a sincere approach will help you to arrive at the best outcome in order to determine the next course of action.

Existing Technologies

Most organizations have one form of technology or several in operation at one time or the other. To develop capacity might require considering the present level of utilization, the efficiency and the possibilities for enhanced optimization. No one should dither when it is clear there is a need for upgrade or outright replacement. While technologies can be costly to deploy, making a fitting choice will in the long run prove advantageous to the bottom-line.

Procedures and Processes

Sometimes, there is a need to develop capacity in specific facets of an organization and this spurs the need to review prevailing procedures and processes. Are the present procedures able to adequately capture what is expected, at what cost and how efficient are they? When this is carefully reviewed, a clear course will be in the horizon.

Some processes are rather too costly, slow and ineffective. Others might be producing results but when it is clear that the organization will be better placed with a change or replacement of process and procedure, it is only wise for a new course of action to be explored and implemented.

Failure to develop capacity lies at the heart of many sub-optimal outcomes. And knowing there is a better deal to ensure higher efficiency and enhanced bottom-line can be a veritable catalyst for change.

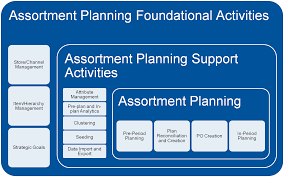

The Basis for Assortment Planning

A Data Driven Basis to Understanding Consumer Demand

Assortment planning is made easy for retailers with the deployment of a suite of mobile apps alongside web versions in order to sell products creatively, efficiently and economically. But this does not just happen without the core step of understanding of customer behavior and disposition. Hyper-connection is a trait that features among modern day consumers and this has made competition to be more intense across all channels.

To be profitable, customer-centred assortments must be anticipated when planning merchandise through the supply and value-chain, down to the store floor. Most retailers are unable to retrieve historical sales data for fast moving consumer apparels when a new line of inventory is heralded by a new season. This is the comfort ground that efficient web and data apps can help retailers maximize when deployed as top-edge solutions.

When the precise capabilities are available, retailers will be better placed to embark on product analysis in order to pinpoint items that have performed well in sales and returns in the past, and be able to project consumer preferences. Vital insights such as colours, brands, silhouettes and fabrics are gleaned and placed side by side unavoidable metrics like price points, in order to zero in on what drives the buying decisions of consumers.

The Assortment Planning Edge

Data-driven Assortment planning is no doubt a scientific process that requires wading through staggering quantum of complementary bits and blocks of data. Analyzing core, relevant and precise data is reduced to routine processes with robust platforms and this is the edge that proactive retailers have over traditional competitors that failed to embrace the dynamism of new technologies.

For example, a clothing retail chain when faced with planning an assortment of 100 items in 5 separate colors and 5 varying size ranges for more than 1,000 outlets over a 4-month horizon will have to grapple with key attributes like fabric, region, climate and price points. This can result to millions of data combinations that the retailer will need to factor-in to arrive at a worthwhile end-point.

However, by deploying the predictive capacity of new technologies, a retailer will be able to conveniently arrive at assortments that will suit each outlet in terms of styles, colors and sizes that will produce optimal returns per location,

When assortments are not just planned but managed at store-levels, a retailer will be better poised to optimize margins with attendant overstocks, stock-outs and merchandise transfers. Assortment planning is vital in supply chain methodologies for real-time feedback in order to pinpoint the bestselling products, their turnaround times and the outlets best suited to guarantee optimal turnover.

Conclusion

To merge the dictates of assortment planning and capacity development is to situate the need for a responsive management system in retail chains. The organization of the future is such that retains an empowered workforce that is able to obtain market data, analyse same and provide a leeway that offers a better outcome in order to satisfy the dictates of the marketplace. Organizations that fail to evolve and develop capacity for such high stakes will falter and eventually get swallowed by the better equipped players who decided to see into the future.