Guide to Buying Walk-in Coolers & Freezers

A guide to your major purchase

Buying a walk-in cooler or freezer is a big decision for any business. There are many things to consider before you make your purchase. You'll need to decide the size of unit you'll need, new or used, standard or custom size, online or offline, what manufacturer to choose, type of insulation, color, with or without a floor, upfront vs. long-term cost, location to put it, refrigeration unit used, accessories needed, and the list goes on.

The purpose of this lens is to help you make sense of it all to make an informed decision.

Where do I start?

The first thing you need to consider in buying a walk-in is what size you need. Consider storage space requirements based on inventory and product delivery schedules. This will help determine the size needed and shelving configuration. On average 28 pounds of solid food will fit in one 1 cubit feet of storage area. You can do the math yourself or contact a manufacturer of walk-in units.

Some manufactures sell standard sized walk-ins that are pre-made so they can be bought online, shipped quickly, and offered to the consumer at a discounted price.

For example U.S. Cooler's standard "Fastcooler" walk-ins measure:

6ft.Length X 6ft. Width X 7ft. 6in. Height

6 X 8

8 X 8

8 X 10

These walk-ins will work for a good number of food service and restaurant applications. But some applications (such as convenience stores or industrial warehouses) will require custom shapes, sizes, and accessories. For these units, simply contact the manufacturer or an authorized dealer to receive a quote on the unit.

What kind of refrigeration should I choose?

Refrigeration systems come in different shapes and sizes, which will affect how much you pay up front and how it performs. A licensed refrigeration technician will be needed to install the refrigeration system.

The different systems are:

1. Remote Systems

2. Pre-assembled Remote Systems

3. Standard Top Mount

4. Side Mount Refrigeration System

5. Saddle Mount Refrigeration System

6. Penthouse Refrigeration System

7. Roll Up Refrigeration System

(Click here for detailed info on refrigeration systems)

To simplify the selection of refrigeration system, first decide whether allowing the condensing unit to dump heat into the building is unacceptable. If it is then a remote unit is the correct choice. Whether it is pre-assembled pre-charged should be decided by evaluating the difference in cost of having it done in the field or at the walk-in plant.

If dumping the heat inside the building is not a concern then choosing a self contained side mount or top mount refrigeration system verses a penthouse or rollup refrigeration unit should be decided by how important the space in the walk-in is to you. If space is important then a penthouse unit is the choice. If space is not a big consideration then side-mount, top mount or rollup unit may be the choice.

Which insulation is the best?

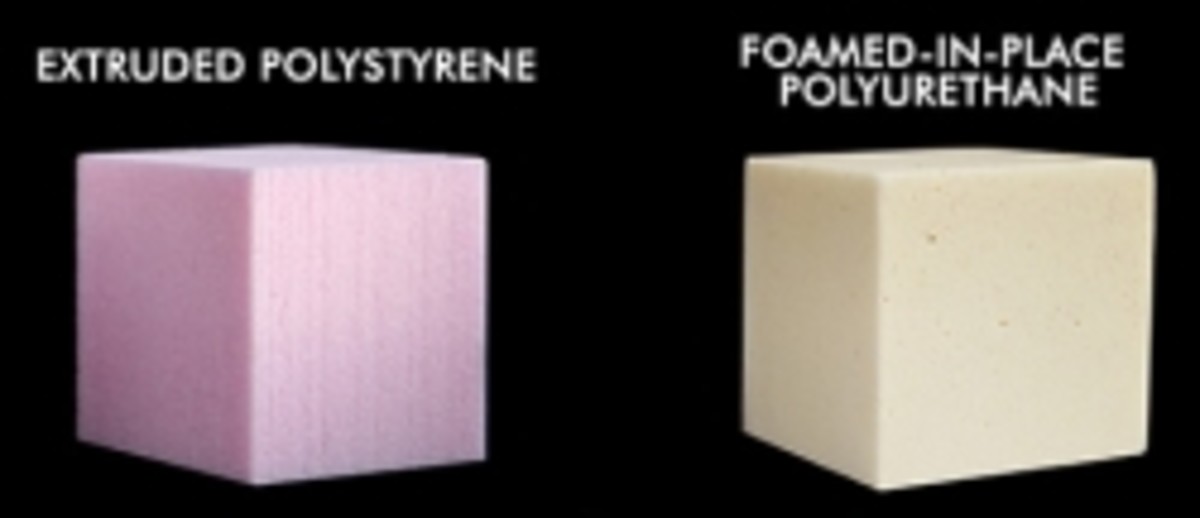

There are primarily three types of insulation used in walk-ins today; expanded polystyrene insulation (EPS), polyurethane insulation and extruded polystyrene insulation (XPS). (image L to R: polyurethane, EPS/XPS Hybrid, extruded polystyrene) If you see a walk-in using any non-foam insulation like wood, or fiberglass don't bother. It probably doesn't meet EISA standards and will cost you thousands of dollars in additional energy costs.

Through experience and research, U.S. Cooler believes extruded polystyrene is the best insulation for the walls, ceiling, and floors of coolers and freezers (and EPS/XPS hybrid is used for our freezers). Polyurethane is better to insulate the doors of our walk-ins. However, you are likely to find manufacturers with differing opinions. Visit this lens for a comparison of polystyrene and polyurethane.

New or used?

Used cars, used furniture, used video games. Many times buying pre-owned products can save you a fortune. Unfortunately with insulated products that is not always the case. You can probably find a used box on ebay, Craig's List, ect. for pretty cheap. But is it really in your best interest? For some businesses, upfront cash is a big issue and in a pinch all they can afford is a pre-owned box. The problem is, while they saved some money up front, the pre-owned unit's energy cost will eat them alive. It's assumed the walk-in unit was manufactured before Jan. 1st, 2009 (which is when the Energy Independence & Security Act went into effect). Units manufactured before this date will in all likelyhood, not meet the new r-value standards set forth in EISA. And that's BEFORE insulation degradation.

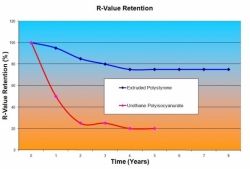

Foam insulation will naturally degrade over time and some will start absorbing moisture in the first year of use. The graph here represents the r-value of polystyrene & polyurethane boxes over time. And of course, the lower the r-value goes, the more money that flies our of your pocket at the end of the month.

Do I need to buy a floor with the unit?

If you are buying a freezer, yes you will need to buy a unit with a floor. The freezing temperature causes problems when mounted on concrete.

With cooler purchases, it is recommended you purchase a floor for increased insulation value. However, anchoring the unit to a laminated concrete floor works well for many people.

Most manufactures will not sell a freezer without a floor, but give the option to purchase coolers with or without floors.

Accessories

When you're purchasing a walk-in through a dealer you will have the option to purchase useful accessories. Some examples include entrance ramps, shelving, strip curtains, and special lighting. Accessories are included for two purposes; convenience and energy efficiency. Strip curtains are great for heavily trafficked walk-ins and minimize air infiltration when the door is open.

You can also purchase them separate through an online retailer. U.S. Cooler has recently launched their online parts website walkincoolerparts.com

Other considerations before purchasing

The service life of a walk-in typically runs between five and 10 years, although some heavy-duty units have been in operation 20 years or more. Operators should weigh a variety of considerations before purchasing a new unit:

* Assess available building space. Due to the high cost of square footage, some operations have located walk-ins outdoors to save space.

* Determine the unit's vertical height and confirm that the building can accommodate something of this size. Typically, operators should allow a minimum of 2' between the walk-in ceiling and the building ceiling to accommodate the unit.

* Assessing the type and condition of the floor and ceiling will ensure proper load bearing and ventilation.

* A functional design remains critical. Determine the number of lights, doors and door width required.

* Look at ventilation space for indoor walk-ins. Typical units require a minimum of 1" clearance on all sides. This allows for deviations in building construction and provides air space for more efficient operation.

Now it's time to finish your research. This is a big purchase, so take the time to weigh your options. Good luck!