SMED: What is Single Minute Exchange of Die

Equipment change-over can consume a lot of the production time and have an impact on customer delivery and cost of production. By using the single minute exchange of die (SMED) technique, companies are able to balance production variety and quantity. This makes it easier to achieve quality, reduce costs and ensure prompt delivery to the customer.

What is SMED?

SMED, which is short for Single Minute Exchange of Die, is a methodology that aims at drastically reducing the time it takes to change-over equipment. It was developed by Shigeo Shingo at Toyota who made it possible to reduce the time it took to change the massive presses that are used in vehicle production. He managed to introduce techniques which reduced the set-up and change-over time of presses to under ten minutes. In fact, the term SMED implies reducing the change-over time to a single digit minute (under ten minutes) and not necessarily one minute.

This reduction is achieved by doing more of the change-over steps while the machine or equipment is still running. These steps, called external steps, can be safely performed while the machine is still running and this reduces the overall time for the entire change-over. Measures are taken on the machine and tools to reduce the steps that can only be done while the equipment is at rest. These steps are called internal steps and SMED aims at converting them to external steps.

Change-over definition

Change-over time is the amount of time it takes to change a piece of equipment from producing the last good part on a production run to the first good part of the next production run. If a defective part comes out of the next production run, the change-over is not yet complete.

Benefits of SMED

When implemented in the proper manner, SMED has a number of benefits:

- Cost reduction is attained because there is less machine down-time and more time is used in the production of saleable products

- Balanced production as more variety can be produced within a specified production run

- Flexibility in the types and quantities of products that can be made

- Inventory reduction is achieved as the lot sizes are reduced and single piece flow is possible as opposed to batch and queue production

- Increased productivity through utilization of the same time and resources such as man-power to produce more products

- Demand smoothing is possible as the facility is able to respond the usual spikes in customer demand that occurs in a typical production set-up

Example of SMED

A good way of understanding how SMED change-over is achieved is to look at a formula-one pit crew as they go about changing the tires of the race car. Since formula-one races are time sensitive and every second counts in determining whether the team will win or lose, the pit crew has to carry-out the tire change and other activities very fast.

They have developed ways of completing the whole exercise in under five seconds by using SMED in that all activities are done while the engine is still running so as to save as much time as possible.

SMED--Steps in achieving quick change-over

Once a production run is complete, the operators have to bring in all the tools, documents, charts, materials and standards required for the next run. This causes machine down-time and the aim of SMED is to reduce the time it takes to produce the first good part on the next run.

The steps that are taken to achieve a successful SMED program in an organization are as follows:

- Identify a pilot area for the program. The purpose of starting with one small area of the facility is to have a benchmark which will be a reference point for all other change-over reduction activities. One should choose a bottle-neck machine that will make a big impact once reductions in change-over times are achieved

- Identify change-over elements, their functions and how long it takes to produce on each element. These elements are divided into human actions and machine actions and should be itemized with a full description of each

- Separate external elements from internal elements. This activity is meant to identify the steps that are currently been done that can be achieved when the equipment is still running

- Convert as many internal elements into external elements. There should be modifications that will result into fewer internal elements

- Simplify remaining elements with an aim of cutting the time required to change-over

Conclusion

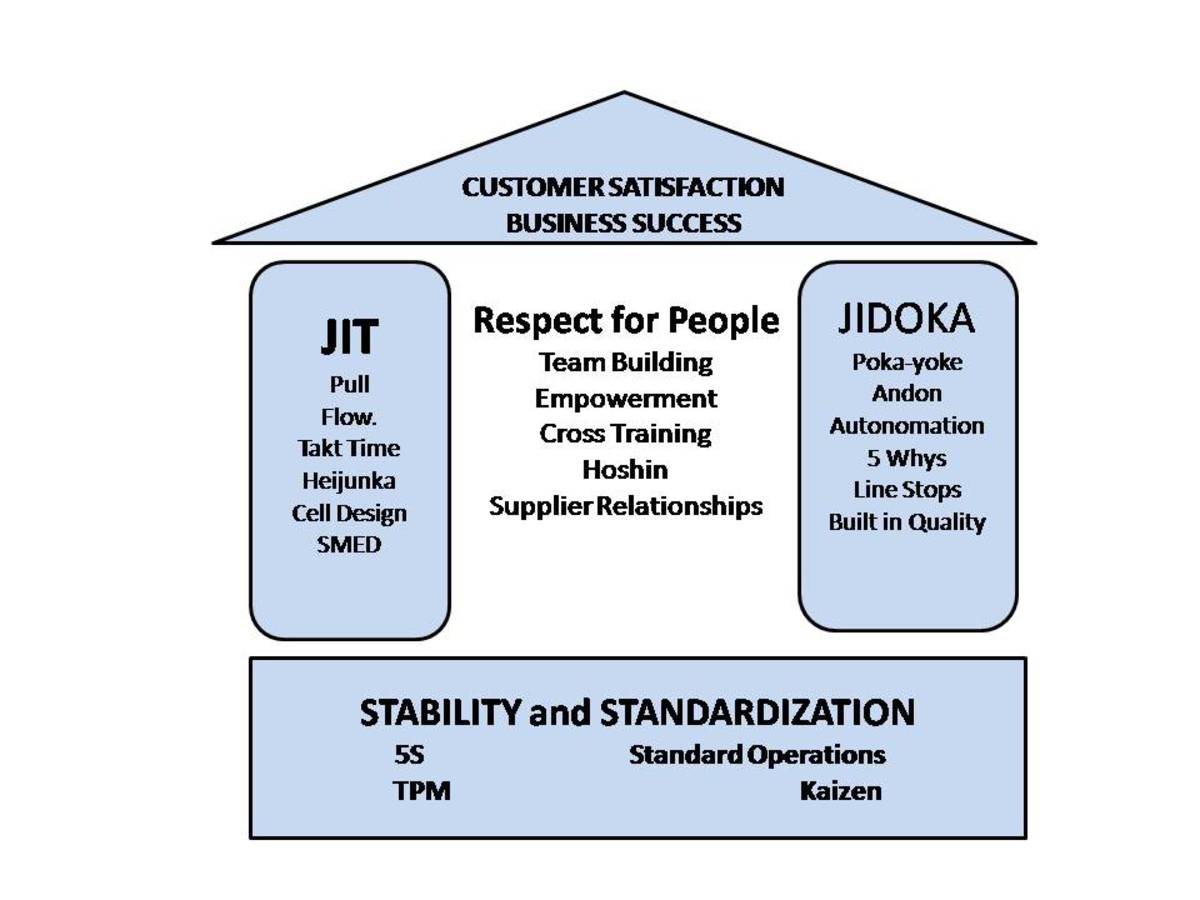

The SMED implementation is a necessary part of the lean transformation because it will be difficult to achieve success without change-over reduction. You will find that a big chunk of the organisation’s time is lost in machine and equipment downtime. These machines become bottlenecks in the process because they disrupt the flow of materials along the value-stream.

Spectacular results in quality, cost and delivery have been achieved when a single minute exchange of die program is successfully implemented. The following table summarises the kind of benefits that can be realized when a SMED program is successful:

Possible Results after SMED

Metric

| Before SMED

| After SMED

| % Improvement

|

|---|---|---|---|

Productivity

| 100 parts/man-hour

| 200 parts/man-hour

| 100%

|

Lead Time

| 2 days

| 1 day

| 50%

|

Change-over time

| 2 hours

| 10 mins

| 91.6%

|

On-time Delivery

| 45%

| 100%

| 120%

|