The Most Dangerous Profession In The World

Mining

Mining is the process through which various minerals and ores are extracted from the ground through mechanized or manual means. These minerals include coal, clay, potash, iron ore, copper, uranium, granite, marble etc., i.e., anything that is held captive within the earth and is brought to the surface by means of machine, use of explosives, or digging with bare hands, using picks, axes and shovels. In the broader sense, extraction of petroleum and natural gas can be termed mining as well, as is drawing water from a well and building a dam since that involves digging and removing earth to access underground water in a well or retain water in a dam.

Mining tampers with the environment by digging underground or excavating from the surface. These are hazardous operations, and nations involved in mining have adopted regulations to prevent such hazards as far as possible. Despite that, disasters happen in regular frequency, either through explosion of gases underground that have been trapped within the earth body and ignited inadvertently, or through collapse of walls at the surface due to loss of stability. Modern practices endeavor to mine as safely as possible, but akin to all situations where nature is tampered, disasters that cannot be predicted do happen regularly.

Origins of Mining

Civilization progressed with the use of tools that were made from metals found within the earth, or the use of earth itself. Clay for pots or flint for tools had to be dug out from the earth, as were rocks and mud for building homes. As civilization progressed, the ancient Egyptians started mining malachite for ornaments as they did other minerals for utility, similar to other civilizations around the world that developed their own necessities and mined accordingly.

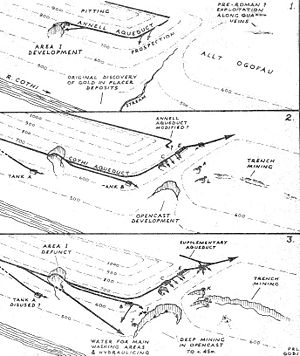

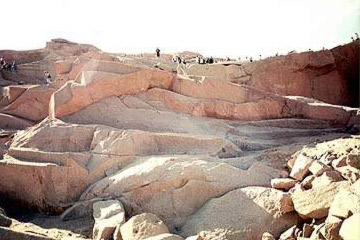

The “Lion Cave” in Swaziland is the oldest mine known, with radiocarbon dating showing it to be 43,000 years old. Hematite was mined here to produce ochre that had a red pigment to it. Flint for tools and weapons was also mined at Hungary during that period. There were mines in Majdanpek, Serbia that operated around 5000 BCE. As stated above, the Egyptians mined malachite, a bright green stone used for ornaments and pottery. They also mined gold, copper and turquoise. The Greeks and Romans also mined, with the Romans adopting technology for the first time to mine large scale. They introduced hydraulic mining for the first time, to wash away the earth covering the rocks containing minerals like gold and then setting fire to the rock and washing it away with a large quantity of water to crack it and thus exposing the mineral. The Romans also went underground following the veins of ore bodies when they were no longer exposed at the surface, and mined them through adit and stope mining.

Mining Methods

Choosing the correct mining procedure depends on the location and size of the ore body or the mineral to be mined. Distribution of the ores or minerals within the earth, their strengths as well as the strengths of the surrounding rocks are all important factors that are considered for developing a plan for extraction.

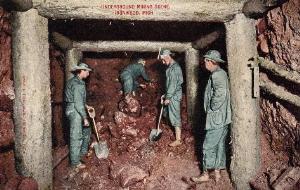

Mining basically involves underground and surface extraction. In underground mining, the access to the location can either be through a shaft, an inclined passageway and transport-way, or through an adit that offers horizontal access to the ore body from the side of a mountain or a hill. These accesses are used for transport of people, machinery, material, and surface transport of the extract.

In opencast mining, the rock or overburden of the mineral is removed to expose the mineral to be mined through an open pit. The mineral is then mined either through machines by digging into them, or through blasting and removal. This method of mining is used when the outcrop of the mineral is near the surface, or in other words when the overburden of earth covering the mineral is thin enough to offer access to the mineral with relative ease. This type of mining is economical until the quarries are so deep that extraction is not feasible.

Hazards Associated With Mining

Mining is known to be one of the most dangerous professions in the world. The dangers encountered by miners in their attempts to extract minerals and ore are many, and depend on their adherence or non-adherence to safety rules that have been laid down by various regulatory bodies. Despite the strictest regulations, accidents still occur with regular frequency. Wherever and whenever nature is tampered with, it tends to pay back with double vigor, as it does to mining.

In underground mines, the following are some of the common causes of accidents that happen with regular frequency.

1. Cave-ins.

When the rocks underneath the ground are excavated to expose the mineral to be mined, the hollow space thus created needs to be supported adequately to ensure that the overlying strata does not cave in. Despite the best of efforts, if the supports are unable to bear the weight of the overlay, the strata collapse. This collapse may sometimes cause subsidence that extends right up to the surface. This happens suddenly without much forewarning, though experienced miners are sometimes able to hear the cracking sounds of the strata prior to its breaking and then caving in. Yet, most times these signals do not give sufficient time to evacuate the area, causing major loss of life. When the subsidence reaches the surface, dwellings overlying the danger zone are also affected, again causing accidents without any warning whatsoever.

2. Explosion of Gases.

This is a major cause of accidents worldwide, ranging from China, Russia, India, the US, and almost all nations that mine underground. Methane gas as a natural occurrence is normally trapped within coal bodies, and unless the mine is ventilated adequately, gas pockets tend to form that are highly inflammable and ignitable with even the slightest of sparks ranging from an electrical short circuit to friction between two metallic bodies or even friction and ensuing sparks when the ore body is struck by a machine. These explosions are devastating, and are a major cause of accidents in underground mining.

3. Fires.

Fires happen for various reasons in mines. They range from gas leaks, self ignition of coal, coal dust explosion, flammable chemical spillage and electrical short circuits. This is again a major hazard associated with mining, and strict regulations by safety authorities have been framed around its prevention, as far as possible.

In addition to the above three major causes of accidents, various other hazards in the form of vehicle collision, chemical leakage, electrocution, slope instability when mining above the ground in benches etc. may also occur. Inhalation of Carbon Monoxide, a lethal gas, when mining underground is also a danger that is omnipresent, as is inundation by a contiguous water body when exposed through mining an adjacent seam. Thus, virtually any disaster can happen at any time during mining.

The 10 Worst Mining Disasters

It is interesting to note that Father’s Day was first celebrated in the US when a lady named Grace Clayton requested her church to hold a Sunday memorial service in honor of the fathers that were lost in an accident at a mine located near Fairmont in West Virginia.

The 10 worst mining disasters in the recorded history of the world are as follows:

1. In April 1942 at Honkeiko Colliery, China, 1549 people died in a mine explosion. This is considered the worst mining disaster ever. The mine was located in Manchuria, a territory occupied by the Japanese who held the Chinese then in scant regard.

2. In March 1906, at Courrieres in France, 1100 miners died due to coal dust explosion.

3. In November 1963, an explosion in a coal mine killed 447 persons in Omuta, Japan.

4. On October 14, 1913, 438 men and boys were killed in Senghenydd, Wales in the worst mining disaster in Britain ever.

5. In January 1960, South Africa had its worst mining disaster at Coalbrook where 437 persons died.

6. On June 6, 1972, a coal mine explosion in Wankie, Rhodesia killed 427 miners.

7. In May 1965, 375 coal miners died in a fire at Dhanbad, India.

8. In December 1975, a coal mine explosion followed by inundation of water killed 372 people at Chasnala, again near Dhanbad in India.

9. On December 12, 1866 at Barnsley, England, 361 persons died in a mine accident.

10. On December 6, 1907, there were 361 casualties at Monongah, WV

Other than the above recorded accidents, China, with its closed door policy, has the worst record of accidents in the world. There are many casualties in such accidents, not much of which is known to the outside world due to the Chinese Government’s policy of not revealing figures and facts.

Whither to Mining?

It is an accepted premise that fossil fuel will not be replaceable in any time in the near future. The necessity of mining for unearthing these fuels, whether it be coal or oil, will thus carry on unabated and at an increased rate in line with the demands of further industrialization and expansion of economies. The need for iron, copper and other minerals will also increase as the world develops. However, the key to sustainability is to mine with a difference and make the process substantially less harmful to the environment through development of new technology. For instance, methane gas trapped within coal bodies can be utilized as an alternative source of energy, thus lessening the demand for increased production of coal and oil as the primary source of energy worldwide. Surface mining removes the entire topsoil from the area being mined, thus causing large scale damage to the environment. Proper forestation techniques to fill up these excavated void sites as early as possible will help in restoring balance to the environment, and thus restore the mined land back to its original green state that is in harmony with its surroundings. The possibilities are endless, but mining will still remain the most hazardous profession in the world until some other profession occupies pole position.