Paul Dobbins and his Aquaculture Adventure

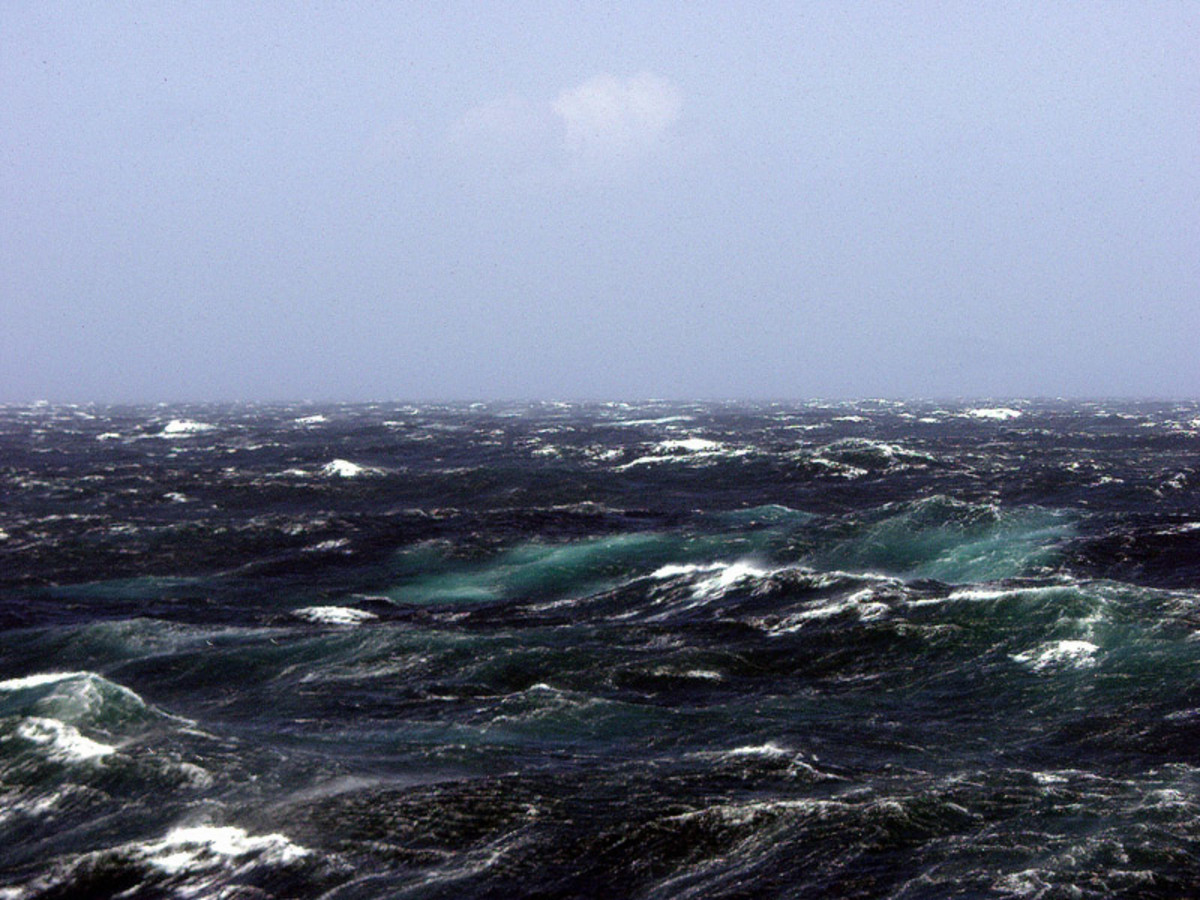

Paul Dobbins is currently employed as the owner of Ocean Approved. He began his work as a scalloper during college in order to pay for tuition while being on the water. He later moved into the biotechnology industry but did not want to spend the better half of his days in an office, so he moved on to mussel farming. Mussel farming was good, but it was a market that was already saturated with businessmen and was not bringing in much profit, and many others already knew how to do it down to a science. He wanted to bring something new to the table and learn new farming techniques while at the same time benefiting the environment. With these goals in mind, he began kelp cultivation. The UN speculates that by 2050, terrestrial food sources will no longer be sufficient to support the population, so the business has room to expand.

Paul traveled to Asia and Europe, where kelp farming is more common, to gain a better understanding of the tactics being used currently. He realized he had to address questions such as: what kind of kelp to bring to the market? What is the best way to do this? Who is the market? How can I appeal to them more than others? He decided that native kelp would be safest so as not to introduce invasive species. He then decided on brown kelps, as they grow faster and larger than red and green kelps, so labor costs were reduced and he could provide a consistent, cheap supply to his customers.

His funding came from the government, specifically the National Oceanic and Atmospheric Administration (NOAA). Since the operation would provide new job opportunities, safe, non-terrestrial, local seafood, and benefit the environment, it was considered overall beneficial to the community. The seafood industry has a 10 billion dollar trade deficit, second only to oil. It has been estimated that 500million-1billion dollars worth of seaweed is imported annually. For these reasons the government has been funding a large amount of aquaculture activity recently. This also implies there is a rather large market for the product, so Paul is entering into a seemingly safe business endeavor. Some people have raised concerns about the effects of aquaculture on the local ecosystems. While this can be the case in many situations, cultivating seaweed actually removes excess nutrients from the water, provides shade and shelter for pelagic organisms, and promotes biological diversity due to the increased habitat creation.

In order to grow kelp, sporangia, which house the algal spores, are harvested from mature kelp. These are inoculated at a density of about 7,000-10,000 spores per mL into nutrient-enriched seawater (indoors) with a bit of germanium dioxide to inhibit nuisance diatom growth. After about 24 hours the spores attach to a surface and are moved to an aquarium to be grown out a bit. Once the spores reach two millimeters in size they are moved to the ocean to continue growing. This eliminates the necessity to provide nutrients needed for growth in an indoor setting as the nutrients are provided naturally. The two millimeter kelp are placed seven feet below the surface to optimize growth and prevent surface disturbances. Gametophytes are stored so that the spawning season can be controlled and there is never a year in which they cannot grow due to lack thereof. All of the materials used to grow are purchased from hardware stores and made as cheaply as possible so that others wishing to enter the industry can emulate and have success without breaking the bank. Paul says that in order to support and develop his own business, he must support the growth of other industry members as well.