Crane Recommendations for material lifting for Jacob's Engeneering Group Ltd

Executive summary

The Company

Jacob's Engeneering Group is an international professional services entity based in New York City, the United States.Established in 1947 by Joseph Jacobs, the entity deals with four key lines of business. They include Infrustructure and buildings, petroleum and chemicals,Industrial, Technology, and Building and Construction. Due to its nature of business and bulk of work involved, the company requires the use of cranes in such operations as loading and offloading products, making excavations, or assisting employees to perform their jobs effectively.

The Focus of this Report

At JEG, similar machines and equipment are used for different functions. For instance, the same machines can be used to move materials horizontally, vertically, loading and offloading and even excavations. Apart from causing the tear and wear for these machines, the efficiency of operations is greatly hampered. What is more, there is no specially designated equipment for lifting materials. Consequently, employees are seen doing so manually which subsequently results in injuries, breakages, and wastage of time and energy(Neizel, 2001). This report seeks to establish the needs of the Jacobs Engineering Group regarding cranes by presenting available options that can increase the efficiency and effectiveness of the operations at the firm.

Key Findings

In this report, we find that Hydraulic crawler cranes, model CKL 1350i, Five-ton Construction Electric hoist winch; model GKS HHBB,380-volt construction winch hoist; model cd/md, and Six-ton Mobile Truck Crane model SonYoun are the possible solutions for a company that needs vertical movements of materials. The Hydraulic crawler cranes; model CKL 1350i, however, stands out as the best machine for the job. The machine has a high weight load, height reach, medium cost of acquiring and maintenance, very safe, and also wide application. Compared to the other construction lifting machines it is more likely to help solve the needs of the organization in an efficient, productive and affordable way.

Key requirements needed

Moving materials from one place to another is among the critical operations at Jacobs Engineering Group. It is critical for the materials to be moved quickly, efficiently and without damage. The work process at this entity involves different natures of materials. Proper handling of materials will reduce losses, avoid injuries and make the entire construction process successful. Accordingly, there have been frequent falls involving employees in construction sites that resulted in more significant fatalities caused by being struck by falling objects. Other injuries were as a result of being caught between the different accidents. This firm therefore that losses a lot from improper handling equipment and less safety equipment. Image 1 shows the fatalities between 2006 and 2014 resulting from construction work. The Bureau of labor recorded 774 deaths as a result of construction accidents of which more than 60 percent were either caused by moving objects or falling objects in 2016 alone. The cost bureau of labor has findings that show that construction accidents result into an average loss of 0.76%, for the uninsured constructors ("Construction Managers: Occupational Outlook Handbook: U.S. Bureau Of Labor Statistics", 2018).

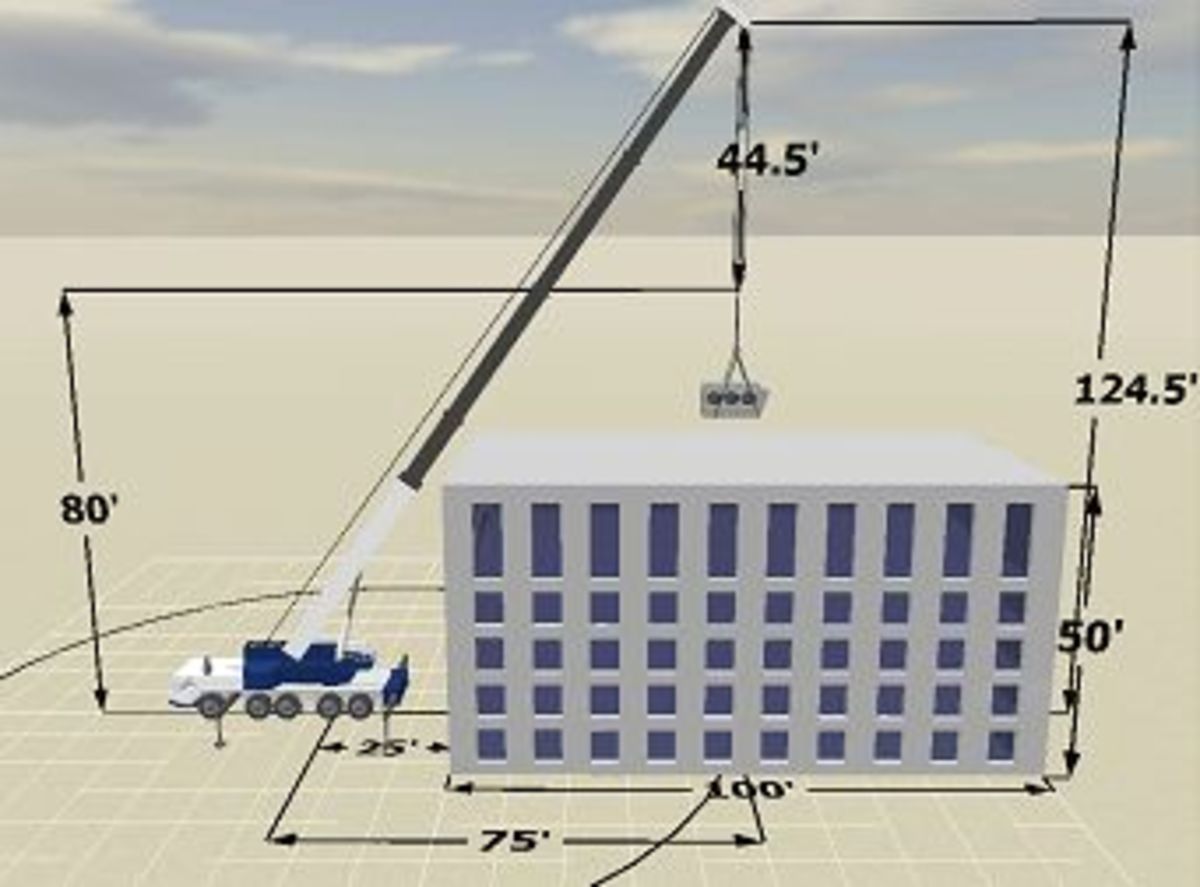

The two-common process that would determine the safety and the success processes at Jacobs Engineering Grou are the vertical movements and horizontal movements. Vertical movement in construction is the up or downwards movement of personnel and objects in construction. There are several ways in which this is achieved. Machines that are used for lifting, lowering and raising objects include the winch, the forklifts, the hoist, vacuum lifting machine, and cranes (Tawfik, 2001). Each of the machines has their strength and weakness. Thus, to have a proper work mobility process, the construction plan ought to have the machine those best suits it needs. The standard metrics for choosing the lifting machines include the building plan, safety, cost, modus operandi, and the lifting process. Buildings with several floors will require lifting machines that can lift objects several meters above the ground. The lifting objects ought to be safe and able to provide safe working conditions for the personnel around the construction site and those working on the machine. The machine should also be able to save on costs in the construction (Akinci, 2003)

Machines are employed in sites to make work easier and reduce the costs. Cheaper machines that can do the same process are usually preferred to expensive lifting machines. The modus operandi is the way the personnel operates. It is the construction process. The machine should not change the construction process; instead, it should be able to improve and quicken the same process. The lifting process will refer to several things such as the nature of the materials being lowered or being lifted up the ground (Gray, 1985). It also refers to the way they are lifted such as internal lifting, that is, the machine is inside the building and external lifting, that is, the machine is outside the building.

In essence, Jacobs Engineering Group lacks a lifting machine. A lifting machine should thus be acquired by the company to be able to lower and raise different construction materials safely while saving on cost and avoiding injuries to personnel(Furusaka, 1984).The organization should be able to use a lifting machine that can be operated easily, that can complement the construction process and not change it altogether.It should be affordable and help in general environmental conservation such as green power and less energy consumption(Kibert, 2016). It should result to less waste, and or proper waste disposal (Khoshnevis, 2015).

Possible solutions

Several machines can move materials up or down a building. Some of the machines such as forklifts cannot operate beyond ten meters which is the third floor for buildings with a floor measuring 3 meters long(Tawfik, 2001). The possible solutions include the cranes and the winches which can go beyond the fourth floor. Thus, the possibilities are the following:

Hydraulic crawler cranes; model CKL 1350i

Cranes are tall machines that are used to move, lower or lift objects in construction sites. The objects are suspended using a beam that is connected on one end to the controller. The controller is a small crawler where the operating personnel operates. The crawler in this model has track rollers instead of crawl tires. The track rollers are to enable smooth mobility at any terrain. The crane is powered by a hydraulic system for maximum pressure for operation. The hydraulic crawler cranes have a boom and a winch to enable it to reach very high and also any place in the building. The maximum height that the crawler can reach is 76.2 meters which Are thus able to reach past the 24th floor for a building measuring 3 meters per floor. The crawler has a swing system which can facilitate a 360 rotation. A 360 rotation is critical in the lifting of things up a building from different angles and locations on the site(Irizarry, 2012). The swing speed is also high to facilitate quick movements. The crane is strong and able to achieve a weight lift of approximately 39.7 ton. It makes the crane one of the strongest machines for lifting and lowering of materials. The upper part of the crane is a winch with a replaceable carrier making it easier to carry different nature of goods. The crane can thus be able to carry heavy materials such as heavy cement and building rocks to delicate materials such as breakable glasses and building linings ("Specifications and Lifting Capacities," 2018).

The crawler controller is a protected cab that is fully fitted with safety glass, armrests, and headrests that also provide for comfort to the operator. The crawler crane is easy to use and does not consume much energy.

1. Five-ton Construction Electric hoist winch; model GKSHHBB

A winch is a chain that is wound up a rotating drum. The drum is rotated. It shortens the chain or elongates it, thereby lifting or lowering the objects respectively.A winch, unlike a crane, needs to be mounted at the top of the building. The building must, therefore, be strong enough to give stability to the winch even when a weighty object is being raised up the building.

The five-ton construction electric hoist winch can carry the weight that amounts to five tons ("Industrial Winches Specifications|Engineering360", 2018). It also uses the electric motor to increase the speed that the chain is wound up the rotating drum. The electric winch is quicker and less prone to accidents than a winch which is manned manually. The winch can be used anywhere; in good working conditions and also in poor working conditions. It can be carried easily due to its lightweight and can be used in different heights such as moving objects from one floor to another floor. The winch has a reverse protection device to reduce wiring error. Practically, if the electricity fails to power the winding up, then the chain will unwind. It may cause accidents and fall of objects that are still in the winch. The reverse protection device stops the circuit hence the chain will fail to unwind. Other than the protection device, it also has a limit switch which enables automatic halt past specific heights or falling to the ground. The limit switch automatically helps to prevent the objects from falling to the ground or colliding with the upper parts of the buildings or the winch (Abdelhamid, 2000). The winch is made up of materials that enable heat dissipation and avoid wearing of the chain.

A winch is a good machine for lifting and lowering lightweight objects up and down the building respectively.

Fig. 2: Five-ton Construction Electric hoist winch; model GKSHHBB

2. 380-volt construction winch hoist; model cd/md

The 380-volt powered winch hoist is a type of pull chain that uses a motor for its winding and unwinding. The model is suitable for heavy materials. T can carry up to 10 ton of material on one trip as compared to the Five-ton Construction Electric hoist winch; model GKS HHBB that has a maximum operational weight of five tons. The 380-volt winch hoist has different features which makes it suitable for hoisting and lowering materials down a building. It has a gearbox that is highly worn and tears resistance to provide for high productivity and low maintenance cost. It is easy to operate. It has both a remote-control button system and a pendant button system to enable for its operation when far away or when near respectively. A motor powers it. The motor is three-phase to ensure it is powerful, can be able to carry heavy weight and also be durable (Tam, 2002). The motors are also fitted with a braking system to be able to halt the operation at any given time to prevent accidents that may be caused by the failure of the machine. It has rope guides, which unlike the Five-ton Construction Electric hoist winch; model GKS HHBB is in two halves ("Industrial Winches Specifications|Engineering360", 2018). It enables the machine to be accessed quickly on both sides. It also provides increased power to carry heavy materials. The ropes are thick for the same purpose. The machine has an emergency halt system that ensures that when the power is off, the machine does not keep on running. Doing so enables it to prevent an accident caused by free falls. The machine can be carried around quickly and can be used in different places, terrains and construction sites.

The 380-volt construction winch hoist is a good machine for lifting and lowering light, medium and heavy materials up or down a building respectively.

3. Six-ton Mobile Truck Crane model SonYoun

The six-ton mobile truck crane is a crane with a truck crawler. Truck crawlers are suitable for their easier mobility. Compared to rollers they can move faster between buildings and around buildings. They are, however. Not as strong as those with rollers. The truck crane has a maximum load of 8.28 ton. It is able to carry 6 ton of materials up and down a building easier. Its maximum reach is 26 meters. For a story building with three meters long floors, it can reach beyond the 7th floor. A truck crane is a machine that has been built for security, mobility, and durability. Its truck is fully enclosed with glass protection and strong body. The crane is entirely operated from the inside of the truck ("Specifications and Lifting Capacities," 2018). It has brakes that are powered by hydraulic systems. It also has automatic safety buttons that would halt the crane in case the internal controls fail. The truck crane consumes a small amount of energy. It operates on a 75Kw engine which is less compared to the above machines.

The six-ton mobile truck crane is a powerful crane that can provide a good system for lifting and lowering materials ina construction site.

Fig. 4: Six-ton Mobile Truck Crane model SonYoun

Criteria for evaluating solutions

Based on the needs of the organization I have chosen the following as an ideal machine for the company. In particular, Jacobs Engineering Group needs a lifting machine that can carry a massive amount of materials over a high distance. It should also be affordable to acquire and maintain. Operating in a construction site should be safe. It should offer a broad application and easy to use. The following are the benefits of the machine:

1.Capability to Lift Heavy Weight load and high reach

The lifting machines are used to lift materials up a building or to lower other materials down a building. In construction, heavy materials are used. Such materials include concrete, sand, metal, rocks, wood, and even clay. The materials are heavy,and a single floor, a dozen hundreds of kilograms or even tons of materials are required to build. Having a lifting machine that guarantees that all the materials can be carried comfortably up the building is paramount. A lifting machine that carries to its maximum is more likely to result in an accident. Khoshnevis writes that for cranes, the materials should not be more than 80% of the lifting capacity to reduce the chances of causing an accident (2015). Many constructors, therefore, use machines that have a bigger capacity to carry weight than they need. The nature of the materials is also essential in choosing the lifting machine. Machines that can carry different kinds of materials are preferred. Machines such as Forklifts are synonymous with carrying regular-shaped materials. They cannot carry irregular shapes like massive rocks without having extra handling (Tawfik, 2001).

The height is equally critical in determining the machine for use in lifting objects up or down a building. Many building currently being constructed have many floors. It means that lifting materials to those floors will require a lifting machine that has a high operational maximum height. If the machine is not able to reach the topmost floor, it means that it will need manual carrying of the materials from the point where the machine reaches the top of the building. It is essential to have lifting machines that have a high reach to operate efficiently (Chan, 1995).

4. Cost of acquiring and maintenance

Construction is a business. Every business owner aims to reduce the cost of operation. The cost of construction is reduced by acquiring affordable products that have higher productivity and ability to meet the needs of the construction organization. Most expensive machines are expected to be of high quality (Tam,2003). It may not be the case most times. Two machines with the same specifications, features, and efficiency may cost differently. The cheaper, the better. The cost of acquiring may be cheap, but the maintenance cost may prove to be high. Cho states that organizations should first find the total costs of operating a machine (2011). The cost includes the cost of acquiring, the cost of maintenance, the cost of operations and the cost of paying the operator. All those costs are vital to finding the total expenditure that the company will incur by choosing to use the machine. Some costs such as electricity consumption may not be readily included in a machine but will always contribute a lot to the expenditures incurred in the machine operation. The standard costs include purchasing price, cost of the operator, number of operators, electricity cost, fuel charge, and cost of acquiring spare parts (Turnbull, 2002). Lowering the cost of construction will enable the organization to channel extra cash to other important causes such as safety, quality materials, and better compensation for personnel.

5. Safety

Safety is vital in construction sites. Safety will lower losses, will help avoid court cases, will improve efficiency, will make maintaining of the building and the equipment easier and will improve the relationship between the personal and the mangers (Shapira, 2009). Safety is the first key thing before any construction work is undertaken. Any machine that proves to be a hazard to the personnel working on the construction site is to be avoided. Safety ranges in the use of lifting machines. Lifting machines have proved to be a cause of accidents in the recent past. Resulting in more than 67 deaths in 2015 according to the Bureau of labor (Construction Managers: Occupational Outlook Handbook: U.S. Bureau Of Labor Statistics, 2018). The deaths being 7% of all the construction deaths caused in construction sites in the same year (Construction Managers: Occupational Outlook Handbook: U.S. Bureau Of Labor Statistics, 2018). The lifting machines can result in accidents such as dropping off materials. The crawlers or the trucks can cause accidents such as collision. Other hazards may be caused from the noise and air pollution (Leung, 1999). Many machines have been improved to avoid the different types of hazards and accidents they cause. Currently, a considerable percentage of the accidents are caused due to human error from the operation of the machines. It is, however, very critical to ensure that the machines are operated in such a way that they can minimize any chance of an accident (Shapira, 2007). Safe machines are recommended. Safe machines include those that can avoid free fall in case of power failure or motor failure, can adjust itself, have automatic brakes, have multiple control stations and can be monitored quickly when they are defective or show signs of being defective.

Safety in construction sites and any other working center is essential. It helps prevent death, injuries, and breakage of materials.

6. Wide application

Lifting machines have the main application being to carry materials up and lowering the materials down a building respectively. The change and advancement in technology have enabled composite machines to be built. Composite machines are those that can be applied in different areas. Some truck cranes have been used for lifting purposes and also used to carry materials from one area to another. some Crawler cranes have been used in leveling of the area in construction and also for lifting and lowering materials up and down buildings respectively(Turnbull, 2002).Broad applications are essential in construction sites that may not be able to accommodate different big machines each having different application. Wide applications have also enabled the organization to save the cost of acquiring different machines for a single purpose.

Other metrics that are also important in evaluating the machine to solve the organization needs wholly include the ease of use of the machine, the number of personnel required to operate the machine and the durability of the machine successfully. The machines may not be able to meet all the criteria. However, the machine that meets most of the criteria is mostly preferred compared to those that do not meet most of the requirements. All the needs are equally important. Safety is however paramount as safety ensures that all the other activities can continue without experiencing other challenges (Gray, 1985).

Recommendation

This section presents a recommendation on the best lifting and hydraulic machines that better suits the interest of Jacobs Engineering Group. From the matrix evaluation above, it is clear that the hydraulic crawler crane is the best lifting machine that will be able to help meet the organization needs. It has a high weight load, height reach, medium cost of acquiring and maintenance, very safe, and also wide application. Compared to the other construction lifting machines it is more likely to help solve the needs of the organization in an efficient, productive and affordable way.

The JEG needs a system that moves materials up and down a building during construction. It is doubtful to use manual means past the third or fourth four(Akinci, 2003). This is because it wastes time, may result in injury, it is very hard and would also result in losses from breakages. Finding a proper way to move the different materials is essential(Tam, 2011). The means for the movement is, therefore, to move all kinds of materials while ensuring that the machine can guarantee safety, it can move a considerable load of materials. The machine can move the goods at greater heights. It is also cheap and durable. Several machines have been made for the work. The different construction lifting machines include the forklifts, cranes, winches, hoist, and vacuum lifting machines. It is important to have a machine that can meet the needs of the organization and also provide value for the investment that the organization makes in purchasing or hiring the construction lifting machine.

In this report, there is no doubt that the Hydraulic crawler cranes; model CKL 1350i is powerful, stable and has all the features that make it carry a heavy load to massive heights. The crane is powered by the hydraulic system which enables it to achieve the maximum pressure for operation. Furthermore, the machine is safe for the people in the construction site and the person operating the machine. It has fitted brakes that are easy to operate to stop the cranes in case of anything going wrong. It is stable hence very unlikely to result to fall of materials.it also has winches that are well connected to the crane to enable proper handling of each load. The individual operating is a protected by the cab that is well and fully fitted with safety glass. The area also is air conditioned with armrests and headrests that make the operator comfortable and protect them from falling materials and or aches caused by improper sitting. This, therefore, makes it a perfect model for Jacobs Engineering Group and similar entities.