Reverse and Forward Osmosis in Desalination

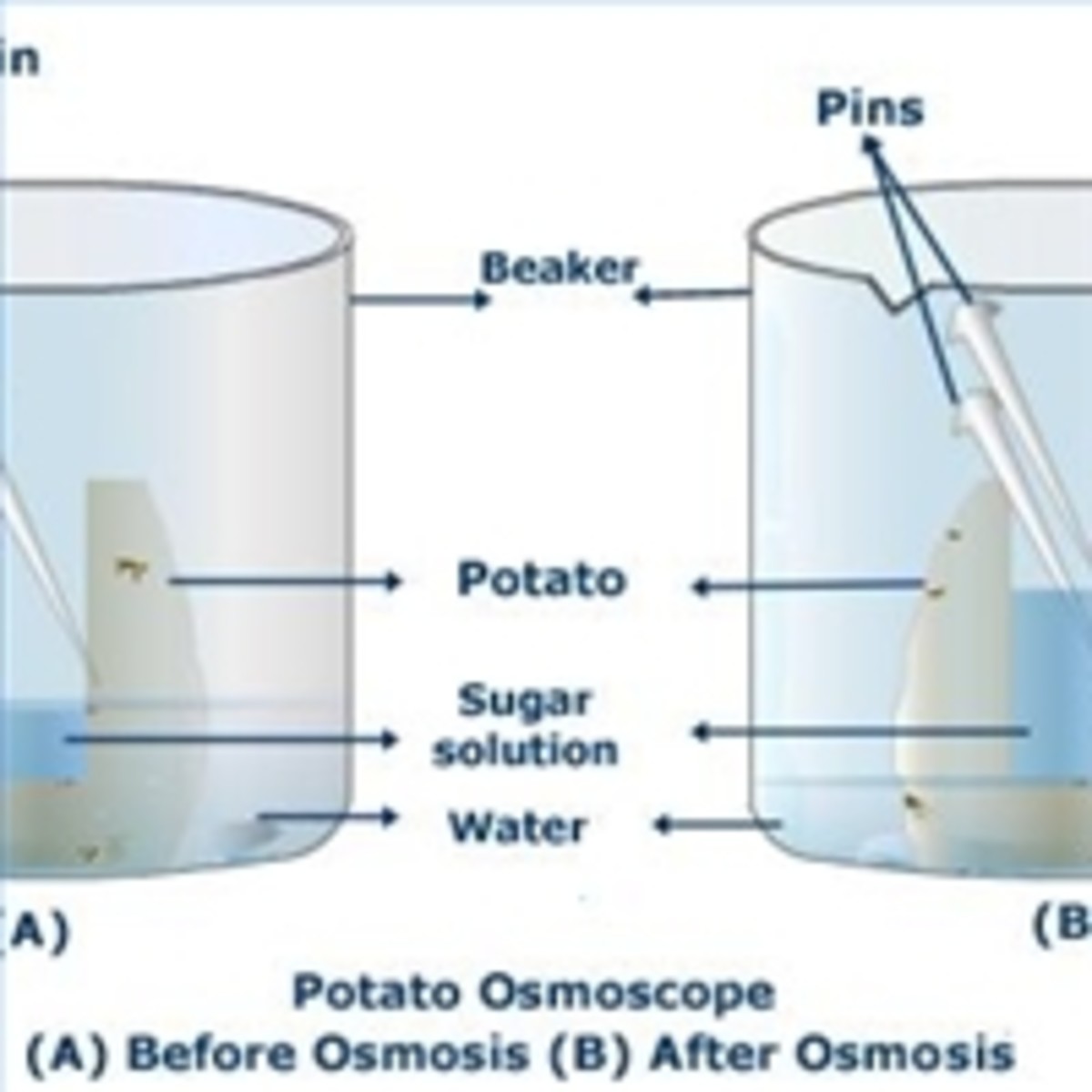

Generally, osmosis occurs when two solutions with different salt concentrations are separated by a semi-permeable membrane, water naturally diffuses through the membrane from the solution with the lower salt concentration into the solution with the higher concentration. If the solution with the higher salt concentration is not allowed to expand, the pressure of the concentrated solution increases and is called the osmotic pressure.

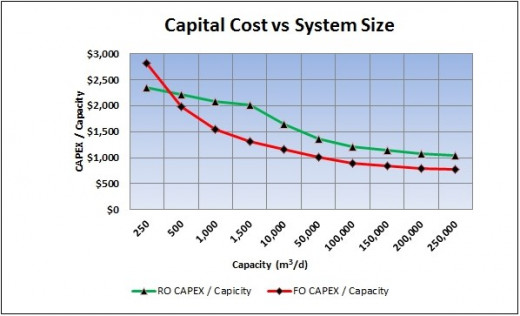

In Reverse Osmosis (RO), if pressure on the concentrated salt solution is increased until it exceeds the solution’s osmotic pressure, water is forced to flow through the membrane from the solution containing higher salt concentration into the solution with the lower salt concentration. The water that diffuses through the membranes is clean product water (permeate). The amount of energy via a pump to create sufficient hydraulic pressure in this system is costly. Forward (direct) osmosis (FO) using semi-permeable polymeric membranes may be a viable alternative to reverse osmosis as a lower cost and more environmentally friendly desalination technology. The driving force in the described FO process is provided by a draw solution comprising highly soluble gases—ammonia and carbon dioxide. The process uses an ammonium bicarbonate draw solution to extract water from a saline feed water across a semi-permeable polymeric membrane. Very large osmotic pressures generated by the highly soluble ammonium bicarbonate draw solution yield high water fluxes and can result in very high feed water recoveries. Upon moderate heating, ammonium bicarbonate decomposes into ammonia and carbon dioxide gases that can be separated and recycled as draw solutes, leaving the fresh product water.

In Trevi Systems Forward Osmosis (FO) uses a unique polymer solution, instead of a pump, to naturally draw (like a sponge absorbs) the solution through the filter membrane after it was chemically cleaned (this unique method avoids the costly pump used to create pressure in RO). Any Brine salts are returned to water source. The partially cleaned solution is then heated using low-cost energy sources (i.e., electrical, gas, solar, or waste heat) before entering the coalescer where additional salt\minerals are separated from the solution. The cleaned part of the solution is scrubbed again through a Nano Filter producing 99% clean product. Separated salts are recycled back through the filter membrane and polymer solution in an endless loop.

There are other types of FO systems, but the uniqueness of having a special solution to create the draw pressure pulling the fresh water out of the salt water stands out. In most systems, a pump is needed to create hydraulic pressure pushing the salt water through the filter membrane, in addition, to a pump to siphon the water from the ocean. The amount of energy needed is excessive. The Trevi System uses far less energy to do the same thing, essentially, making it a a very "green" way for desalination in arid countries. The heat used also can originate from solar, waste heat, electrical etc. The costs will vary depending on location and electrical versus non-electrical costs.

Benefits of the Trevi system are:

- The process has the ability to desalinate ocean water at 1/8th the electrical energy of current RO systems (0.5 kWh/m3)

- Trevi FO system uses ‘waste heat’ or low grade thermal heat at 75 C to drive the FO desalination process.

- Trevi system’s heat requirements are approximately 50MJ/ m3

- The brine stream generated may be concentrated to either very low or very high recovery rates without a noticeable change in electrical energy consumption, allowing the system to be tailored to the environmental requirements of the customer.

- The draw solution maybe varied in concentration to allow higher or lower osmotic pressure for specific water conditions such as brackish water, municipal waste, industrial etc.

- The Trevi FO system operates at ambient pressure, lowering plumbing costs.

- The Trevi FO system will benefit from lower membrane fouling due to the nature of FO system. Thereby lowering maintenance costs and membrane replacement intervals may be reduced.

- No high pressure pumps in the Trevi System.

- Draw solution lifetime is to be determined but is expected to be greater than 2 years

There are several FO companies competing and pushing the envelope with this technology. Independent studies and simulations, apart from the competing companies, have yielded great results from competing companies. The results of the simulations are compared to the energy requirements of current desalination technologies. Energy savings of FO compared to current technologies, on an equivalent work basis, are projected to range from 72% to 85%!

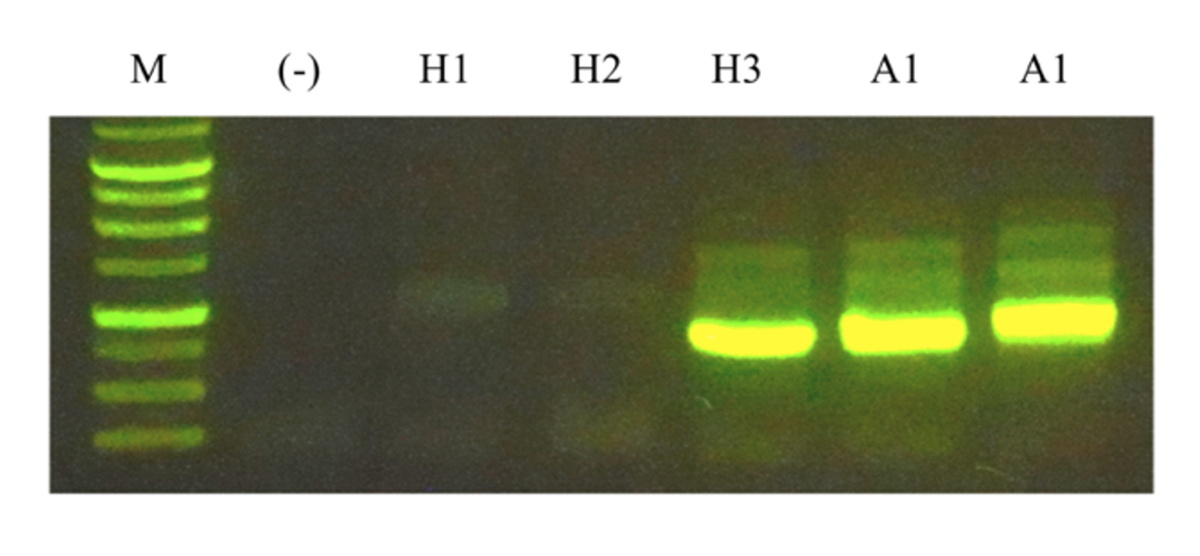

Desalination of saline water for irrigation, using fertilizer as a draw agent, is also being explored by some companies. Instead of separating the draw solution from desalinated water, the diluted fertilizer draw solution can be directly applied for fertigation. The most soluble fertilizers can generate osmotic potential much higher than the sea water, which is very important. There are currently nine commercial fertilizers available to test. The results of the tests indicated that the draw solutions of KCl, NaNO3 and KNO3 performed best in terms of water flux while NH4H2PO4, (NH4)2HPO4, Ca(NO3)2 and (NH4)2SO4 had the lowest reverse solute flux. The independent studies showed that that 1 kg of fertilizer can extract water ranging from 11 to 29 L (4-11 gallons) from sea water.

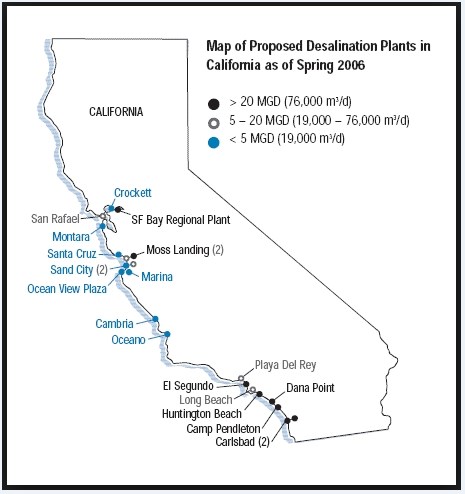

The FO method is proving to be the wave of the future for many water cleansing needs, from desalination to municipal needs in a much more "green" and inexpensive manner. The need for fresh water is critical in California, in Carlsbad, Calif., construction is 25 percent complete on a $1 billion project to wring 50 million gallons of freshwater a day from the sea and pour it into a water system that serves 3.1 million people.