The Basic Principle of Iron Smelting

Iron ore

Iron is a metal that is very useful for human life and is widely used today besides gold and silver or copper.Iron is used to make tools such as knives, machetes, hoes, shovels, hammers and even motorbikes, cars and planes. The use of iron continues to increase with an increase of 2% each year. In the small industry in our society, iron is still processed by forging smelting plates, only large industries process iron ore by smelting. In this article I will try to explain the basic principles of processing iron ore by smelting which can be applied to small and medium industries.

How do you get iron ore?Iron ore is contained in the earth's crust or in the soil and some is contained in river sand. We can do a simple test to test whether there is really iron ore content in the sand. For that, take a magnet, then rub it into the sand, you will see a blackish iron ore attached to the magnet. For more details, watch the following video:

Test to determine the presence of iron ore in the sand

Testing iron ore

This trial is only to test the presence or absence of iron ore in the sand but cannot be used to mine iron ore because this type of trial will only get very little iron ore.

Then how do you get or mine iron ore. Iron ore that is in the ground is mined by excavation and obtained iron ore mixed with other minerals, iron ore like this is metallic in color ( see photo of iron ore above ) and is ready to be smelted, other minerals will be lost or exhausted by smelting . Meanwhile, the iron ore contained in river sand must first be extracted from the sand by panning it like gold paning, then it is ready to be smelted. Apart from panning, there are other ways, namely that the sand is burned in a tub above a furnace until the iron ore melts and collects into one, then the iron ore is melted back to make equipment.

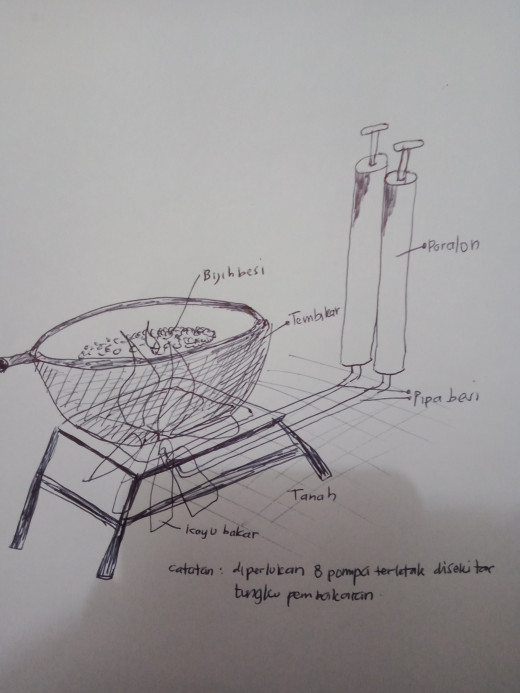

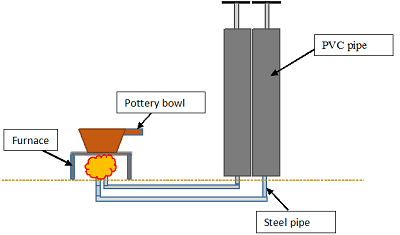

The basic principle of smelting iron ore is that iron is smelted by fire that is blown or pumped manually or by machine. The fuel can be firewood or natural gas. The basic principle is that ore that has been obtained by panning or mining is put into a container or bowl made of pottery or ceramic.

The fire is continuously blown or pumped with a manual pump like the picture above made of paralon pipes then flowed through an iron pipe under the furnace or you can also use a compressor engine until the fire temperature reaches the melting point of iron, which is 1375 ° C-1500 ° C. To melt iron, it takes 8 pumps from the pipe in the four corners around the furnace. In smelting iron ore, at least five workers are needed. In this blowing process, an oxidation process occurs which causes the temperature of the fire to increase to a high temperature which can melt iron. In addition, the melting point of iron is the highest of all metals on earth except tungsten. So this basic principle can be used to melt other metals such as gold, silver and copper.

The basic principle of smelting iron has been applied in the village of Limpok, Aceh Besar, near the city of Banda Aceh, and has succeeded in smelting iron and copper for making various kinds of equipment.

That is the explanation of the basic principles of traditional iron smelting, hopefully this is useful.

This content is accurate and true to the best of the author’s knowledge and is not meant to substitute for formal and individualized advice from a qualified professional.

© 2020 Mahlil