Homemade Visco Firework Fuse

Learn about visco firework fuse and how to make your own.

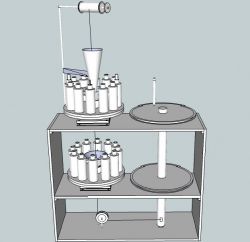

This page is about making visco firework fuse and promoting a blog which hosts a comprehensive eBook with plans and instructions for making your own visco machine (as seen on the right). Go to the blog by Clicking Here.

For those that appreciate the beauty, thrills and mechanics of fireworks, making your own is both rewarding and exciting. All fireworks carry some level of risk but having a safe and reliable fuse greatly reduces the chances of damage or injury. That's why it's so important to have a fuse you can trust! Even for the amateur pyrotechnic enthusiast, there will quickly come a realisation that a safe and reliable fuse is not only an essential piece of kit for successfully setting off fireworks predictably, but that they are the most underappreciated part of any firework.

There's a lot more information on the blog about making visco fuse than there is on this page, so be sure to check it out if you're interested by Clicking Here!

A background to making firework fuse

There are many places where restrictions on the sale of fuse prevents (or makes it difficult for) a pyrotechnic enthusiast to obtain fuse. Even where you can purchase fuse you might be looking to pay a relatively high price for a short length. That's why so many pyrotechnic enthusiast look to making their own fuse. There are many types of fuse with different properties designed to fulfill different requirements. Arguably the most important of these (at least initially) to the budding enthusiast is the fuse used to initially light a pyrotechnic device. The best of which is called visco fuse.

Visco fuse is the type used to light almost all consumer fireworks and is therefore the most familiar to us all. Visco style fuse has many advantages over other fuse types (as described below) but does require a little work to produce it. Keep reading to see how easy (and fun!) it can be to make your own visco style fuse.

So what is visco fuse and why should you make it?

William Bickford is credited as the creator of safety fuse (the forefather of visco fuse) and is said to have been inspired by the process used to make rope. Bickford created safety fuse for mining applications but the same principals were used to make cannon fuse (for early artillery) and visco fuse for fireworks.

Visco fuse consists of a core of explosive powder with two sets of counter spun cotton thread wrapped around it. This forms the basic structure of the fuse which is then coated with a binding agent, typically nitrocellulose lacquer. The primary function of the lacquer is to prevent the cotton threads unraveling. Additional qualities the lacquer provides are to make the fuse durable (withstanding break and lift charges) and waterproof.

Lots of people make fuse paper and blackmatch as their chosen fuse as it's seen as being easier to make than visco. Whilst this is true of the initial outlay of time and resources, once you've made a visco weaving model it's actually faster and a lot less hassle to make visco than fuse paper or blackmatch.

An important point is that although fuse paper and blackmatch can prove adequate, it's much less reliable than visco style fuse as can be seen in the video below.

Fuse comparison... and why you should choose visco

Fuse paper can easily be blown out and whilst blackmatch is unlikely to go out its burn rate rapidly increase with increased airflow, neither of which is good for safe timings of fireworks. Visco fuse doesn't have this issue.

Fuse paper and black match are both unreliable in confined spaces as shown in the rocket nozzle example in the video, often going out just as the fuse reaches the exhaust port. Again, visco fuse doesn't have this problem.

Finally the lighting and burn rates of fuse paper and blackmatch are unreliable. Fuse papers burn rate will often slow and speed up again whilst blackmatch tends to burn a little too fast for ideal use in firework timings. In any event neither of these are suitable for more complex devices as they'll not withstand the force of a lift charge/break charge. The final clip shows blackmatch burning too fast, whilst fuse paper doesn't light at all in this example. Visco style fuse ignites perfectly and burns with a slow and steady rate.

Visco style fuse is also waterproof.

All of this goes to show why you should choose to make visco style fuse over more basic types of fuse.

Get step by step instructions for making your own visco fuse machine

So, now that you've seen that a visco style fuse is far superior to other fuse types the question remains "how do I make it?"

Well, although there is a wealth of information out there and many people have made their own visco machines unless you've got access to a workshop and a fair amount of technical knowledge these devices might be beyond the fabrication skills of most beginners and tend to put people off.

I distinctly remember trawling through site after site trying to find information on how to make my own visco machine but they were all incomplete. After piecing together the information there was still a lot of trial and error in getting the machine to work correctly. I remember thinking "if only there were some instructions... I'd definitely buy them!"

I wanted a visco machine that was; compact, hand powered, easy to construct, cheap to build, easy to operate, quiet and able to produce small to medium lengths of fuse easily and quickly. After lots of redesign I eventually made a machine that fulfilled all of these requirements. The design is both very simple and highly effective and can be seen in action by Clicking Here.

When I made my visco machine I went to a lot of effort to make detailed instructions and plans on how it was built with a view to making a step by step guide that others could follow to make their own.

I compiled all of this information together into an eBook and made it available on my blog! Simply click here or on the source links under any of the pictures to go to my blog. In addition to the eBook the blog has a lot more information about making visco fuse as well as its applications - so please feel free to pay it a visit!