How to Make Metal Moulding Box

Moulding Box Construction

Introduction

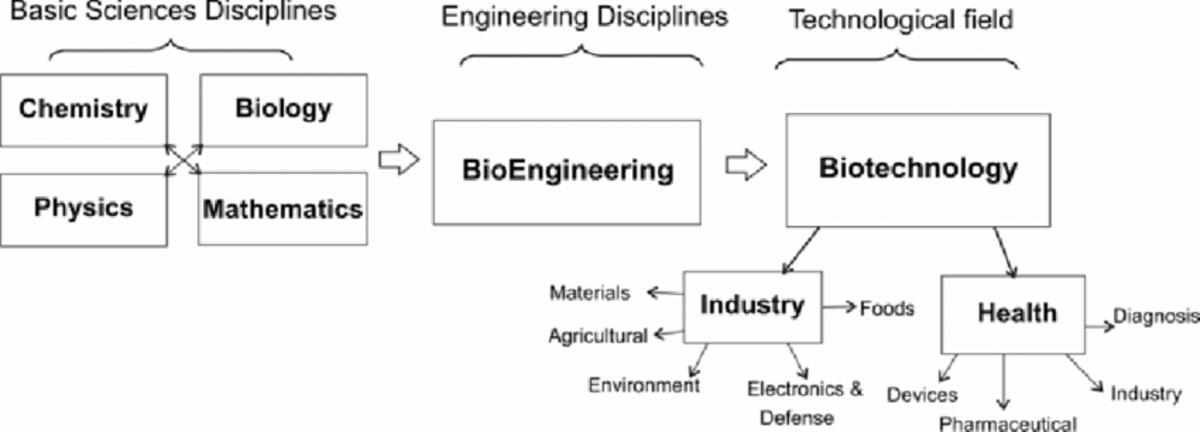

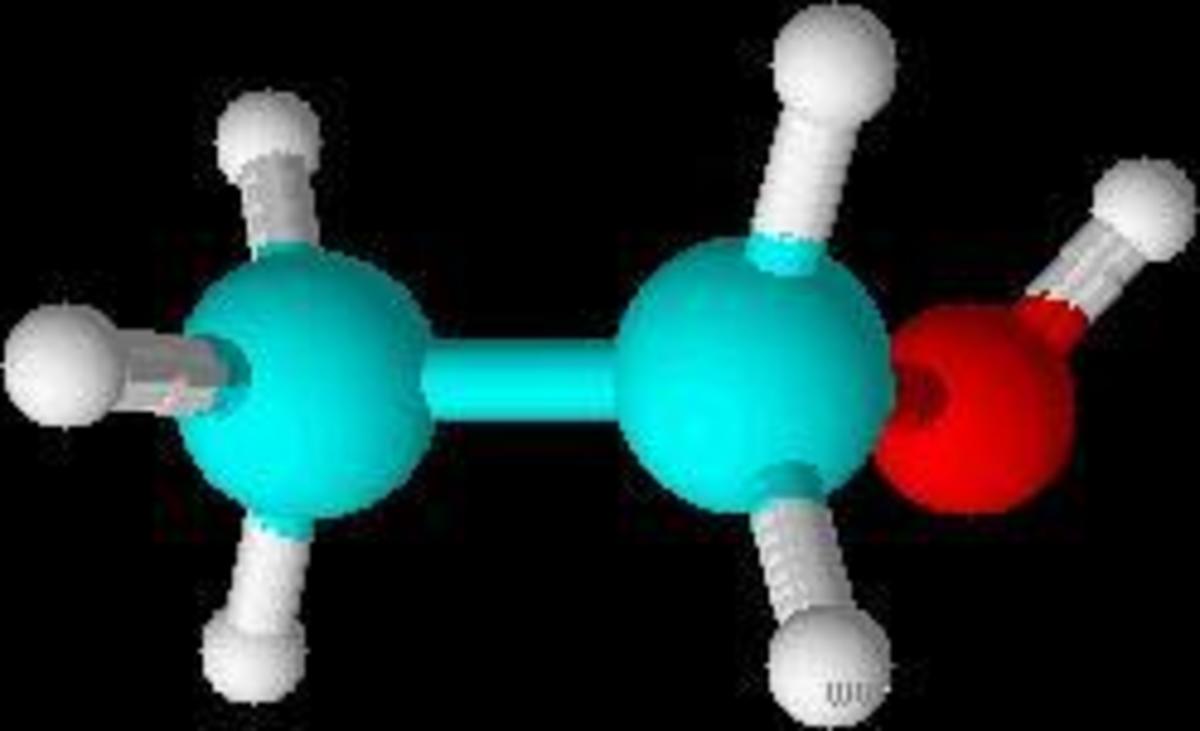

How can moulding box be made? Molding box or moulding box is a shaped object made of wood, Plastic or metal which is used in casting processes of various kinds and shapes. This piece will teach you how to make moulding box. Note that ‘mold’ is used by the United States while ‘mould’ is used by the Britain; so do not be confused. They are made in segments that may be matched to each other and to end closures. I wonder how the automobile department will be without metal molding box because some important parts are made with the help of molding box. Engine blocks and other cast parts of automobiles came to be because of the help offered by metal molding box. Cylinders used in water drilling machines were achieved as a result of metal molding box. It is the molding box that holds molding materials and molten metal together before the final result is achieved (cylinder). In this note, I am discussing on the production of metal molding box. This is based on the personal and practical work experience. That is why I have the video of sequences or procedures on how to make mold box in this text. This starts from the cutting, folding hammering and even teachings on the parts of the metals to be welded together to form the final structure which is the molding box.

Metal moulding box has many important applications in the field of engineering. More specifically, the box is usually applied by Mechanical and Metallurgical engineers.

Mold boxes cannot be done without in many engineering or production companies in the world and, think of how the world of today will be without the use of molding boxes for many engineering works. The parts of many automobile are being achieved with the help of molding boxes. These can be manufactured with sand casting processes or other related casting processes. In foundry, many patterns are cast into real shapes because of the help offered by mold boxes. Metal moulding boxes are used for sand casting process. A foundry is a place where castings are made. Castings are the products which are produced during casting process from the used pattern.

The Steps in Making Metal Mold Box

This sub-topic discusses the step in making metal mold box. The devices and the instruments used in this production of the molding box are: mild steel sheet, steel rule, Chalk, hammer, leg vice, cutting saw, metal rod, electrodes, welding machines and the face shield. The steps are explained below:

Cutting: The flat mild steel sheet is cut into long rectangular length. This is the done after the marking out process. The molding box produced in this writing is square in shape. The dimensions used are 10*10*10*10. These dimensions are in millimeters. The four lengths of the molding box or mold box to be formed are to be ten millimeters each. Note that tolerance of about 3mm (millimeters) is to be given to obtain a proper result at the end of the formation process. This is because during the folding of the steel metal sheet, there will be decrease as the bent portions take some measurements of the total 40 millimeters. The length then tends to be shortened and the 10mm of each side will no longer be obtained. So, to avoid shortage of the square shape, the 3mm is considered and included in the formation. The tolerance of 3mm is also included to help during welding of the final end points. This part of the measurement sticks to the ‘body’ of the box.

Folding: The already cut-out length of the mild steel is folded to form the square shape of the mold box. The folding is done in a leg vice. The marked parts of the box are placed between the vice, tightened between the Leg Vice and finally bent. The marked out portions of the molding box is bent into shape to make the box. When each side is bent, it is hammered with the use of hammer. This will be well understood with the video attached to this write-up. Ensure to protect your hand while folding to prevent cut.

Welding: After bending the mild steel to form the four cornered shape of the molding box, the two end points are being welded together to form the final shape of the box. These end points are welded together using electrode gauge 12. The gauge 12 is used because the mild steel used in the construction is light. It is also used because it forms molten pool and has the ability of welding the two points firmly together. The type of electrode gauge used is dependent on the functions to be performed during the welding. Gauge 10 and 9 electrodes are used when the aim of the welding is mainly to produce molten pool.

Construction of the Mold Box Handles

Measure out a total length of 11 inches from a metal rod. Mark out 3 inches from each extreme ends of the rod. The next is to bend the already 3 inches which was measured out to form a U-shape with the 5 inches as the base. Mark-out one inch from the top of the 3 inches of the both sides. Finally, the one inch from both sides is bent to from an angle of 90 degrees. The bent one inch is the part to be welded on the body of the mold box to form the handle. The handle is properly welded on the mold box so that it will not fail during casting process using the box. When the handle is not properly welded, accident can be encountered in the foundry workshop. Molten metal can pour on the body of the worker during casting as the handle collapses. Tight welding must be ensured to avoid this accident. Note that the constructed handles are two so that the box can easily be carried during casting.

Conclusion

Engineering companies prefer metal molding boxes to others made of other materials. The reason is because of the benefits associated with it. One of them is its durability.

Molding or mold box cannot be done without in many manufacturing engineering companies that deal on casting with metals. The processes that take place during making of molding box were detailed out. The video for easy understanding of this process is also included to aid understand. The molding process which requires mold box is a versed course in many branches of engineering study. The major engineering departments that make use of this box are the production, mechanical and metallurgical engineering. The foundry engineers cannot do without mold box as that is the major instrument they use in the workshop. Mechanical engineers that construct automobile parts use the box to form the needed parts. Mold boxes take many shapes depending on the casting to be made. If you are working on this as a project, it is believed that this will be of good help to you.

© 2013 Uzochukwu Mike