How to Build a Storage Building

Why Build with Steel

Steel increases in popularity each year. As the industry grows, everything improves. Building methods, available materials, distribution systems, material availability and the number of builders knowledgeable in steel construction, increase each year. Steel construction is expanding in application. It grew from a commercial building specialty into agricultural buildings, school buildings, and even churches.

Some of the innovations are design standards, innovative sections to form connections, and insulated wall panels. Insulated wall panels are easily installed, and complete the building envelope in one installation process. Often, these are available with a finished exterior; there is no requirement for a finishing coat.

Cheapest Way to Build a Steel Building?

Which Process do You Think is Least Expensive Overall?

Manage the Process Yourself

This article focuses on methods to ensure receiving the best building possible while preserving capital for other investments. The primary way to do this is to manage the project yourself. If you are skilled at managing projects, overseeing others, and ensuring timelines and budgets, this is for you. If you have more time than money, this is also something for you to consider.

Many owners hire subcontractors to perform every function. The contractor serves as intermediary for the owner and hires an engineer, draftsman, special inspector, electrician, and any other specialists.

One way to save money on a project is to perform this work yourself. It's a win for the contractor, too- most of the time. There are some reasons hiring a contractor directly may be the best option:

Most contractors have been in business many years. They have cycled through different engineers, electricians, other specialists, and workers. The professionals they work with have been vetted. They are tested and reliable. However, a good contractor earns a good salary. He is worth it. (I would say, "or she", but I don't know even one female contractor.)

In 2010, I engineered several steel buildings for a dairy. The contractor told me this story:

"I quoted this guy a year and a half ago. He thought my price was too high. So, he hired some day laborers and brought them out to dig footings and put up some poles for a freestall barn. Three months into it, he realized those guys work so slow, and make so many mistakes, it'd be cheaper for him to hire me. So, now he calls me."

Choosing the Right Contractor

Why a Good Contractor is Worth his Salt:

The contractor in the story is one of the best in the Central Valley. After more than 30 years in the business, his employees are skilled, proficient, and fast. In business, a building is constructed because it creates or saves money. A faster building is worth more to an owner than one constructed more slowly.

Why a Contractor will Quote a Lower Price:

The contractor makes money by careful preparation, recruiting the best talent in the field, and efficiency. For him to manage every aspect, he loses time. This means he can complete fewer jobs per year and will earn less money- unless he charges to perform management and coordination of plans preparation, communicating with the engineer and draftsman, approving things with you, and acquiring documents from you, like a parcel map of your lot.

If you can manage the design and engineering, and production of plans, the contractor knows the project will move quickly, and he can earn a good profit for his time. This means you can get a lower quote for the work.

Hire Your Own Special Inspector

A special inspector is required in virtually every county and city. This inspector is not a city employee. A special inspector certifies certain critical aspects of construction. These might include high strength bolt tightening, welds, or construction of masonry walls in high seismic areas.

When a special inspector works for a contractor, his loyalty is to him. When you hire the special inspector directly, and pay personally, loyalty is directly to you. Either way, the ultimate cost is yours.

Note: some buildings do not require special inspection. In fact, my personal design process makes every effort to avoid special inspection.

Secondary Markets for Metal Buildings

Another way to save money in steel building construction is to search secondary markets. Secondary markets include auctions, online auctions, classified ads, and networking.

It is not uncommon for a land owner to purchase a pre-engineered metal building (PEMB), take delivery to his site, and then never assemble it. If you find one of these, you will likely get a much better price than if you purchased it directly.

There are two important checks you should make before purchasing a building kit in this way.

- Ensure the engineering is current, and the owner still has it.

- Inspect materials with a site visit.

If the kit does not have current engineering, engineering designed to the current codes, then local building officials will not accept the engineering package, even if nothing at all has changed in regards to load combinations or processes to calculate design forces. You will need new engineering calculations. I have seen quotes from a few different PEMB companies for updating the engineering calculations. They are usually a little more than $3,000. The ones I have seen were all shops, about 2400 to 3000 square feet.

Light gauge steel panels can sometimes rust when resting flat. If the pallets have properly been propped at an angle, any rainwater will most likely have run off. A covered kit is also a good indicator. However, you will most likely not be able to inspect every component until you have it on your own parcel and cut the binding straps.

It may be wise to negotiate a portion of the payment for a kit purchased on the secondary market until after all components have been inspected, or maybe even until the building is successfully erected. You may not notice a missing, damaged, or corroded member until construction is under way.

Here is a very good photo series on the construction of a steel building:

Comments on Video:

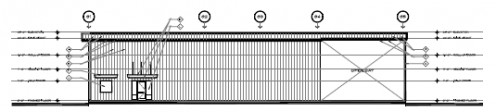

Notice at 5:20 the builders use some temporary bracing to support the frames. The finished building utilizes the metal siding to resist all wind forces. In the end, they cut three windows and a door into one wall. This significantly reduces the shear resistance capacity of that wall.

To compensate for the openings, cross braces should be installed, or concentric bracing. In this building, concentric bracing is used in the end wall (at 5:00 and at 5:50.)

Discounted Metal Buildings

It is not uncommon to visit a PEMB company's website and see buildings at deep discounts. Sometimes, buyers put down a deposit, and the seller fabricates all the parts and assembles the pallets for delivery, awaiting final payment.

...and the buyer backs out.

This is your opportunity to get a good deal on a building. Just remember that a larger building also means higher permit fees and more tax every year. In assessing an opportunity, be sure to figure in the long term costs as well as immediate fees.

Excellent deals can also be found on Amazon.com.

One Secondary Market is Amazon.com. Opportunities below are available NOW.

How to Build a Steel Building Foundation

Before a contractor can erect a steel building, he must build the steel building foundation. Foundations must be designed by a licensed engineer in most counties in the U.S. Some counties permit construction by owners. Phone the local building department to learn the requirements in your jurisdiction.

For large buildings, a soils report will be required in most counties. California now requires soils reports even for the smallest of buildings. The default allowable load in the International Building Code is 1,500 pounds per square foot (psf.) Most soils reports allow 3,000 psf. So, for very large buildings, a soils report can produce savings in material costs that exceed the cost of the report itself. This will net savings for the owner.

If a PEMB is purchased, the builder, such as CECO Buildings or ABC Buildings, will send the future owner sets of plans and engineering calculations. Provide a copy to the engineer who will design the building foundation. The calculations contain reactions required to design the footings.

How to Build a Slab for a Steel Storage Building

The basis of a good slab, for a steel building or any other type, is proper preparation of the site and soil.

First, after the permit is in hand, and any required erosion protection is erected, clear and grub the work area. If clay is located, contact your foundation engineer immediately. Typically, the solution is to double the weight of the footing. The additional mass presents the clay from shoving the building after heavy rains. Similarly, if soft earth is located, double the width of the perimeter footing.

Second, the most important factor in slab serviceability is soil compaction. Soil must be compacted to 90% for most storage buildings. For some uses, the engineer may specify 95% compaction. But, this is not expected for steel buildings. Slabs typically comprise 4 to 6 inches thick, with #3 reinforcement bars in both directions, spaced at 24” on center.

Steel buildings have long service life. Steel buildings are a more recent structural type in the construction industry. Those built 60 years ago remain in service. Though rare, the most common problem in a steel building is shifting of the foundation. The building type is not the controlling factor; it is conditions of the soil that cause foundation issues. Primarily, failure to clear organic debris or top soil before preparing the ground, or failure to identify soft soil or clay cause unsightly cracking in foundations.

Some cracking is normal. Preferably, cracks will be less than one-quarter inch in width. Most will be smaller and evenly distributed. this is normal and unavoidable. To control the propagation of cracks, the contractor will cut control joints, also called crack joints, into the cured slab. These should be spaced at maximum 15 feet on center, and should be evenly spaced. Thinner slabs required closer spacing of control joints.