What is Lean Thinking; Review and Explanation

Lean Thinking by James Womack and Daniel Jones

Lean Thinking is a book by James Womack and Daniel Jones is a follow on from their original book the Machine that Changed the World; the book that introduced us in the west to the term Lean Manufacturing.

Lean Thinking is a book that challenges traditional ways of business thinking that tolerate and in some case produce waste in our business systems. It seeks to instill a mindset that is focused on the creation of value (as perceived by the end user) and the elimination of Muda or waste.

Lean Principles

Buy Lean Thinking

Lean Thinking Review

Lean thinking gets us to understand how an organization can promote value and remove waste through some lengthy and detailed case studies following the lean journey of a number of organizations over several years and shows how these companies have profited from the implementation of lean thinking.

The book itself could be hard going for someone that is not a lean enthusiast with over half the book given over to the case studies. However in my mind it is a book that is a must read for executives and senior management in any organization that wishes to improve. Some of the ideas in the book are bound to trigger those little light bulb moments that you need to improve your ways of thinking and working.

Having seen the principles of lean being implemented first hand within the Automotive industry from the early 1980s onwards as the west struggled to copy the success of Toyota I have read many books on the subject, whilst this may not be the easiest read, it is one of the best!

Lean Thinking Hardcover

Lean Thinking Alternative Reviews

There are a number of reviews of Lean Thinking out there on the web and some of the most useful I include here. Firstly here is a review from MIT where the original study into the automotive industry that gave us the name lean, a name that the authors wished had been chosen differently due to its “mean” connotations and anorexic implementation in some areas unlike the athletic and versatile organization that they had envisioned!

Also a couple of bloggers within a couple of other industries and other manufacturing philosophies have also reviewed Lean thinking and I include links to their reviews as they contrast the lean approach to their field of TOC and to the Software Industry.

Lean Thinking Womack

James Womack and Lean Thinking

James Womack is one of the Authors of Lean Thinking and has been heavily involved in Lean since the early 1980s when he and his Co-Author Daniel Jones took part in an MIT sponsored study of the Automotive Industry. This study showed that Toyota was performing significantly better than any of its competitors through the application of what it called the Toyota Production System (TPS) and the research team dubbed “Lean Manufacturing”.

The book Lean Thinking is a follow on from their original book entitled the Machine that Changed the World and continues their research into the philosophy known as lean.

Since then James has gone on to be the founder and chairman of the Lean Enterprise Institute in the US, a position now held by another renowned lean author John Shook.

Daniel Jones Lean Thinking

Dan Jones and Lean Thinking

Daniel Jones also worked on the original study at MIT and has also moved into consultancy by becoming the founder and chairman of the Lean Enterprise Academy in the UK and continues to promote Lean Thinking.

Daniel is very much active in Lean Manufacturing within the UK and continues to write with James Womack on a number of joint projects.

Lean Thinking for the Kindle

What is Lean Thinking

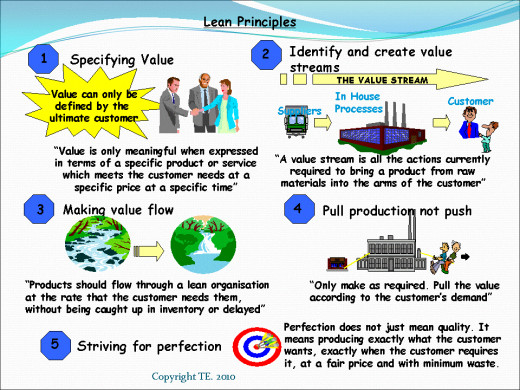

What is lean thinking? James Womack and Dan Jones identified five principles of lean manufacturing in their initial work and those were;

- Identify Value as perceived by the Customer (end User)

- Identify and create the Value stream

- Make value flow with delays

- Pull from the value stream at the demand of the customer

- Strive for perfection.

Focus on Customer Satisfaction Not Just Removing the Seven Wastes

Lean Thinking is Not Just Waste Removal

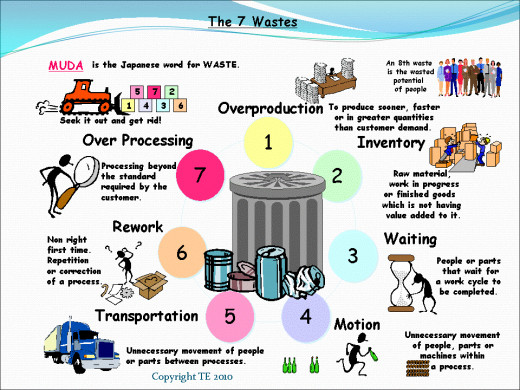

These lean principles still hold true and are what lean thinking is all about, not as some would say as a focus to remove waste from your processes. The removal of waste or Muda is a result of these principles not the other way around. There is no point making a process more efficient and removing waste from it if the process itself adds no value!

By implementing lean manufacturing according to these principles rather than just focusing on waste you can truly have a lean organization. But to do this you need management commitment, a good understanding of the lean principles and respect for and the involvement of all employees. The benefits of Lean Manufacturing are huge as shown within the books by Womack and Jones; since the original book was written Toyota has overtaken GM as the biggest automobile manufacturer in the world and has none of the money worries that have plagued GM.

Lean Thinking Video

Lean Thinking Summary

Just what is Lean Thinking as specified by Womack and Jones? Well to summarise you can break lean thinking down into a single paragraph;

"Clearly specify value in order to line up all the activities for a specific product (family) along a value stream and make the value flow smoothly at the pull of the customer in pursuit of perfection."

If you can run your business by these simple principles you will as the book suggests; banish waste and create wealth within your business. We are all in business to make a profit, and this can only be done in the long term by concentrating on our customers not by looking for short term gains.

Lean thinking is the way to improve your business and to keep your customers satisfied and coming back time after time.